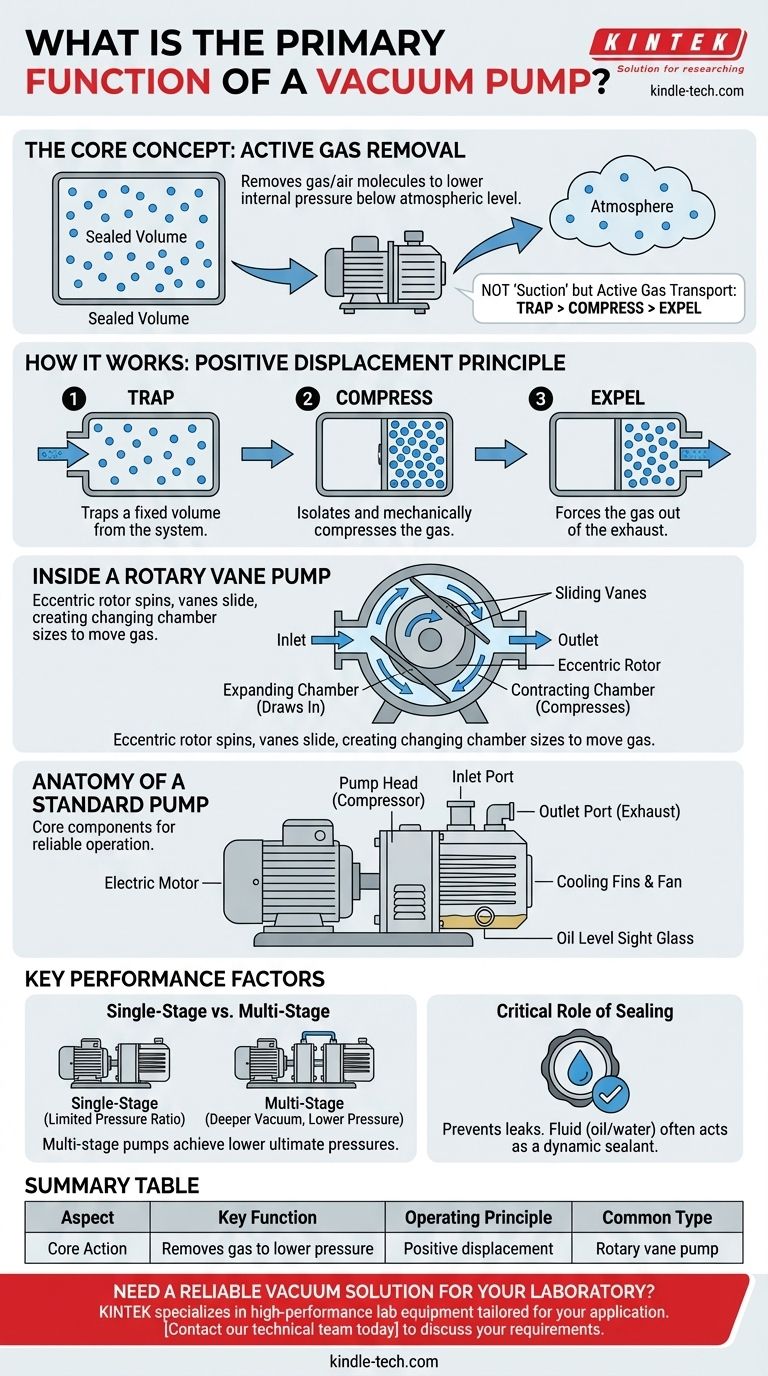

At its core, a vacuum pump's primary function is to remove gas or air molecules from a sealed volume. By capturing and expelling these molecules, the pump reduces the number of particles inside the container, thereby lowering its internal pressure to a level below the surrounding atmosphere. This process of creating a partial vacuum is fundamental to countless industrial and scientific applications.

A vacuum pump does not create "nothingness" through suction. Instead, it is a mechanical device that actively traps, compresses, and transports gas out of a sealed system, systematically lowering the pressure inside.

How a Vacuum Pump Creates Lower Pressure

A vacuum pump operates on principles of gas displacement and compression. It's helpful to think of it not as a device that "sucks," but as one that moves gas from a low-pressure area to a high-pressure area (the outside atmosphere).

The Principle of Positive Displacement

Most vacuum pumps are positive displacement machines. This means they trap a fixed volume of gas from the sealed system, isolate it, and then mechanically force it out of the pump's exhaust.

This action is repeated rapidly, with each cycle removing another pocket of gas, progressively lowering the pressure within the system.

The Mechanical Action of a Rotary Vane Pump

A common design that illustrates this principle is the rotary vane pump. A rotor is mounted off-center (eccentrically) inside a cylindrical housing.

Blades, or vanes, are set into slots in the rotor. As the rotor spins, centrifugal force pushes these vanes outward, keeping them in constant contact with the inner wall of the housing.

Because the rotor is off-center, the chambers created between the vanes continuously change in size. A chamber expands as it passes the inlet, drawing in gas from the system. As it rotates further, the chamber shrinks, compressing the gas until it is forced out of the exhaust port.

Other Displacement Mechanisms

Other designs achieve the same goal through different mechanical actions. For example, a rotary screw pump uses two intermeshing screws to trap gas in the threads, transport it along their length, and expel it at the other end.

Anatomy of a Standard Vacuum Pump

While designs vary, most vacuum pumps share a set of core components that enable them to function reliably.

The Motor

The electric motor is the powerhouse of the pump. It provides the rotational energy needed to drive the internal mechanism, whether it's a rotor with vanes or a set of screws.

The Pump Head (Compressor)

This is the heart of the operation, containing the mechanism that creates the vacuum. It houses the rotor, vanes, and cylindrical casing (or screws) that capture and compress the gas.

Inlet and Outlet Ports

The inlet port is the connection point to the sealed system you wish to evacuate. The outlet port, or exhaust, is where the captured and compressed gas is vented out of the pump, typically into the atmosphere.

Essential Support Systems

To ensure longevity and performance, pumps include critical support systems. A cooling fan and fins on the casing dissipate the significant heat generated during gas compression.

Many pumps are oil-lubricated, and an oil level sight glass allows operators to monitor the quantity and condition of the oil, which is vital for sealing and lubrication.

Understanding the Key Trade-offs

The effectiveness of a vacuum pump is not absolute. Its performance is defined by key operational variables and design choices.

Single-Stage vs. Multi-Stage Pumps

A vacuum pump works against a very high pressure ratio—the difference between the low-pressure inlet and the atmospheric-pressure outlet. A single-stage pump has a physical limit to the pressure ratio it can achieve.

To reach deeper vacuums (lower pressures), multi-stage pumps are used. These are essentially two or more pumps connected in series, where the exhaust of the first stage becomes the inlet for the second, allowing for much lower ultimate pressures.

The Critical Role of Sealing

The ability to create a deep vacuum depends on preventing leaks. Seals are critical, both within the pump mechanism and in the system it's connected to.

In some designs, a fluid like oil or water acts as a dynamic sealant. For instance, in a liquid ring pump, the amount of seal water is crucial. Too little prevents the pump from reaching a stable vacuum, while too much wastes energy without improving performance.

Applying This Knowledge

Understanding these functional principles allows you to operate, troubleshoot, and select equipment more effectively.

- If your primary focus is maintenance and operation: Pay close attention to support systems like oil levels and cooling, as they are the first line of defense against pump failure and performance degradation.

- If your primary focus is system design: Match the pump's specifications (such as its ultimate pressure and displacement rate) to your application's requirements, deciding if a single-stage or multi-stage design is necessary.

- If your primary focus is fundamental understanding: Remember that a vacuum pump is a gas-moving machine that works by mechanically trapping and expelling gas, not by a mysterious "sucking" force.

By viewing a vacuum pump as a specialized gas compressor, you gain the clarity needed to optimize its performance and ensure its reliability in any application.

Summary Table:

| Aspect | Key Function |

|---|---|

| Core Action | Removes gas molecules from a sealed volume to lower internal pressure. |

| Operating Principle | Positive displacement: traps, compresses, and expels gas. |

| Common Type | Rotary vane pump (uses eccentrically mounted rotor and vanes). |

| Key Components | Motor, pump head (compressor), inlet/outlet ports, cooling system. |

| Performance Factor | Single-stage vs. multi-stage design for different vacuum depths. |

Need a reliable vacuum solution for your laboratory?

KINTEK specializes in high-performance lab equipment, including vacuum pumps tailored for your specific application. Whether you require precise pressure control for research, sample preparation, or industrial processes, our experts can help you select the ideal pump to ensure reliability and optimize your results.

Contact our technical team today to discuss your requirements and discover the KINTEK difference in laboratory performance.

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Variable Speed Peristaltic Pump

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the aim of sintering? Transform Powder into High-Performance Components

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition

- Why graphite Cannot conduct electricity? Unlocking the Secret of its High Electrical Conductivity

- What is the analytical method XRF? A Non-Destructive Guide to Elemental Analysis

- How does magnetron sputtering work? A Guide to High-Quality Thin Film Deposition

- Can SLS powder be reused? Yes, with the right refresh rate strategy.

- Which lab grown diamond process is best? Focus on Quality, Not the Method

- How does a high-power ultrasonic homogenizer assist in the preparation of organic-inorganic nanocomposites?