Calendering is a high-volume manufacturing process that transforms a molten polymer into a continuous, high-quality film or sheet. In this method, the heated and plasticized material is passed through a series of large, rotating rollers that squeeze it into the desired thickness and apply a specific surface finish. While primarily associated with Polyvinyl Chloride (PVC), it is also suitable for other select thermoplastics.

The core purpose of calendering is to achieve superior control over sheet thickness and surface quality at production speeds that other methods cannot match. It is a process chosen for its precision and efficiency in very large-scale applications.

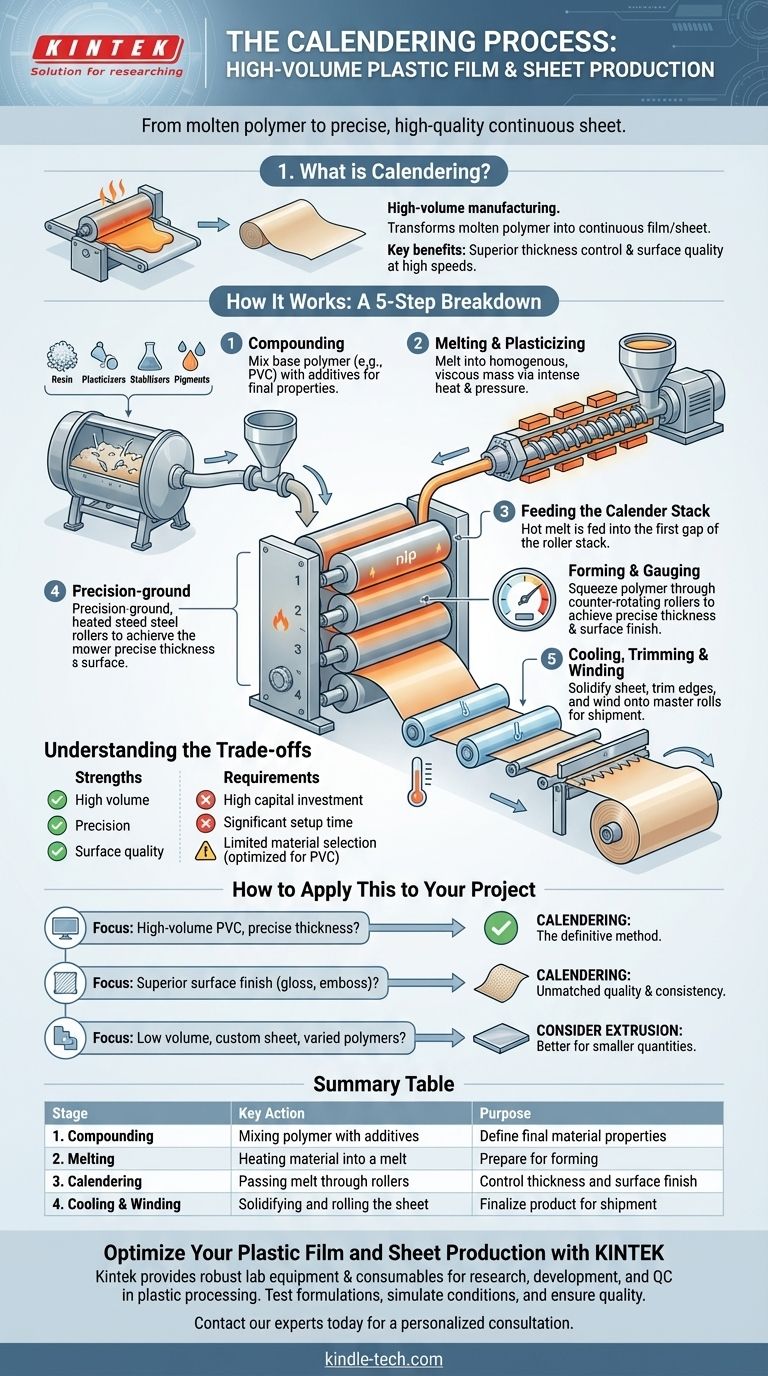

How the Calendering Process Works: A Step-by-Step Breakdown

The calendering line is a complex, integrated system. Each stage is critical for ensuring the quality and consistency of the final product.

Step 1: Material Compounding

Before melting, the base polymer resin (e.g., PVC) is dry-blended with a variety of additives. These can include plasticizers for flexibility, stabilizers for heat resistance, pigments for color, and fillers for bulk or specific properties. This initial compounding step dictates the final characteristics of the sheet.

Step 2: Melting and Plasticizing

The compounded material is fed into a continuous mixer or an extruder. Here, intense heat and pressure are applied to melt the material into a homogenous, viscous mass known as a "melt." This ensures the material is at the correct temperature and consistency for forming.

Step 3: Feeding the Calender Stack

The hot polymer melt is then fed into the "nip" – the gap between the first two rollers in the calender stack. The calender itself consists of a series of (typically four) large, heavy, precision-ground steel rollers that are heated internally.

Step 4: Forming and Gauging

The material winds its way through the stack of counter-rotating rollers. Each successive nip is progressively smaller, squeezing the polymer and accurately gauging its thickness down to the final specification. The final set of rollers often determines the surface finish, which can be high-gloss, matte, or embossed with a texture.

Step 5: Cooling, Trimming, and Winding

Immediately after exiting the last calendering roll, the hot sheet is passed over a series of cooling rollers to solidify it and lock in its dimensions. The edges are then trimmed for uniformity, and the continuous sheet is wound onto large master rolls for shipment or secondary processing.

Understanding the Trade-offs

Calendering is a powerful process, but it is not universally applicable. Its strengths are balanced by significant operational requirements.

High Initial Capital Investment

A complete calendering line is an enormous piece of industrial machinery representing a multi-million dollar investment. The rollers themselves are extremely expensive and require high-precision engineering.

Not Suited for Low Volumes

The process involves significant setup time to heat the rollers, dial in the correct gauges, and purge the system between material changes. This makes it highly inefficient and cost-prohibitive for short production runs or prototyping.

Limited Material Selection

The process is optimized for materials with a specific melt behavior, like PVC. While other materials like ABS or certain polyolefins can be calendered, the material must be able to withstand the high shear forces between the rolls without degrading.

How to Apply This to Your Project

Choosing the right manufacturing process is critical for balancing cost, quality, and volume.

- If your primary focus is high-volume production of PVC film or sheet with precise thickness control: Calendering is the definitive and most cost-effective method for this application.

- If your primary focus is achieving a superior surface finish (e.g., high gloss, leather-like emboss) directly in-process: Calendering offers unmatched quality and consistency for creating integral textures and finishes.

- If your primary focus is producing a few hundred feet of a custom sheet or working with a wide variety of polymers: You should specify a more flexible process like flat die extrusion, which has lower setup costs and is better suited for smaller quantities.

By understanding where calendering excels, you can make an informed decision that aligns your project's technical requirements with the most suitable manufacturing technology.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Compounding | Mixing polymer with additives | Define final material properties |

| 2. Melting | Heating material into a homogenous melt | Prepare for forming |

| 3. Calendering | Passing melt through precision rollers | Control thickness and surface finish |

| 4. Cooling & Winding | Solidifying and rolling the sheet | Finalize product for shipment |

Optimize Your Plastic Film and Sheet Production with KINTEK

Navigating the complexities of high-volume manufacturing requires the right equipment and expertise. Whether you are scaling up a calendering line or exploring alternative methods like extrusion for smaller batches, KINTEK is your trusted partner.

We specialize in providing robust lab equipment and consumables that support research, development, and quality control for plastic processing. Our solutions help you test material formulations, simulate process conditions, and ensure your final product meets the highest standards of quality and consistency.

Let's discuss how we can support your project's success. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Small Lab Rubber Calendering Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What is the role of a laboratory crushing and sieving system in microalgae pyrolysis? Enhance Your Yield Efficiency

- What is the difference between calendaring and calendering? Master the Key Spelling and Context

- What is the process of calendering? A Guide to High-Volume Plastic Film Production

- What is the difference between grinding and pulverizing? Achieve the Perfect Particle Size for Your Application

- How does a grinding mill work? A Guide to Crushing, Grinding, and Pulverizing