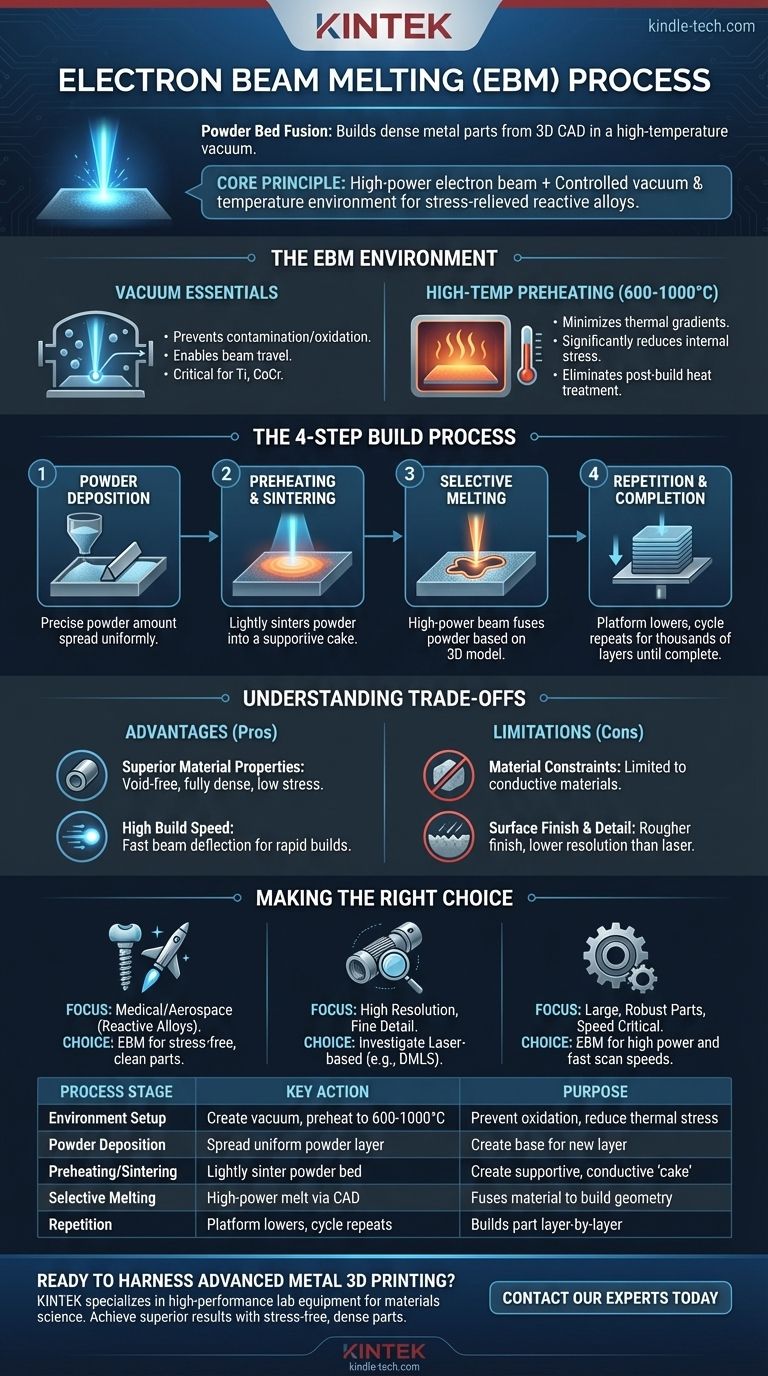

Electron Beam Melting (EBM) is a powder bed fusion technology that builds fully dense metal parts directly from a 3D CAD model. It uses a powerful, computer-controlled electron beam within a high-temperature vacuum to melt and fuse successive layers of metal powder, creating complex geometries that are impossible to produce with traditional manufacturing.

The core principle of EBM is its unique combination of a high-power energy source (the electron beam) and a controlled environment (high vacuum and high temperature). This process is specifically engineered to produce stress-relieved parts from reactive and high-performance alloys.

The EBM Environment: Vacuum and High Temperature

Before any melting occurs, the machine must establish a very specific environment. This is the primary factor that differentiates EBM from other metal additive manufacturing processes.

Why a Vacuum is Essential

The entire EBM build process takes place in a high vacuum. This serves two critical purposes. First, electrons cannot travel effectively through air, so the vacuum provides a clear path from the beam emitter to the powder bed.

Second, the vacuum creates an oxygen-free environment. This is crucial for preventing the contamination and oxidation of reactive materials like titanium and cobalt-chrome, ensuring the final part has superior material properties.

The Role of High-Temperature Preheating

EBM operates at exceptionally high temperatures, often between 600°C and 1000°C. Before the selective melting begins, the electron beam preheats each new layer of powder.

This high-temperature environment minimizes temperature gradients within the part as it's being built. This significantly reduces internal stresses, which is a major advantage that often eliminates the need for post-build stress-relief heat treatments.

The Step-by-Step Build Process

Once the environment is prepared, the layer-by-layer build cycle begins.

Step 1: Powder Deposition

A hopper dispenses a precise amount of metal powder, and a recoater blade or rake spreads it into a thin, uniform layer across the build platform.

Step 2: Preheating and Sintering the Layer

The electron beam, operating at a lower power setting, rapidly scans the entire powder bed. This step lightly sinters the powder particles together.

This creates a semi-solid "cake," which provides support for the part being built and helps conduct heat and electricity away from the melt zone.

Step 3: Selective Melting

Following the 3D model's cross-sectional data for that specific layer, the electron beam's power increases dramatically. It precisely traces the component's geometry, fully melting the powder particles and fusing them to the layer below.

Step 4: Repetition and Completion

The build platform lowers by the height of one layer, and the process repeats. A new layer of powder is spread, preheated, and then selectively melted. This cycle continues for thousands of layers until the final part is fully formed, encased within the cake of semi-sintered powder.

Understanding the Trade-offs

Like any manufacturing process, EBM has a distinct profile of advantages and limitations that make it suitable for specific applications.

Advantage: Superior Material Properties

The combination of a vacuum and high-temperature preheating results in void-free, fully dense parts with low residual stress and a microstructure similar to wrought materials.

Advantage: High Build Speed

An electron beam can be deflected using electromagnetic coils, allowing it to move almost instantaneously between melt points. This, combined with its high power, often results in faster build rates compared to laser-based systems.

Limitation: Material Constraints

EBM relies on the electron beam to heat the powder, so the process is limited to conductive materials. It is not suitable for polymers, ceramics, or non-conductive composites.

Limitation: Surface Finish and Feature Detail

EBM typically uses a larger powder particle size and creates a larger melt pool than laser-based methods. This results in a rougher as-built surface finish and a lower resolution for very fine features or thin walls.

Making the Right Choice for Your Goal

Selecting EBM requires matching its unique process characteristics to your specific application needs.

- If your primary focus is producing medical implants or aerospace components from reactive alloys like titanium or Ti-6Al-4V: EBM is often the superior choice due to its stress-reducing high-temperature process and contamination-free vacuum.

- If your primary focus is achieving the highest possible resolution, finest feature detail, or a smooth as-built surface: You should investigate a laser-based technology like Direct Metal Laser Sintering (DMLS).

- If your primary focus is manufacturing larger, robust parts where speed is critical and a rougher surface finish is acceptable or can be machined later: EBM's high power and fast scan speeds offer a significant production advantage.

Ultimately, choosing EBM is a decision to leverage a high-energy process that excels in creating strong, stress-free parts from some of the world's most advanced materials.

Summary Table:

| Process Stage | Key Action | Purpose |

|---|---|---|

| Environment Setup | Creates a high vacuum and preheats to 600-1000°C | Prevents oxidation, reduces thermal stress |

| Powder Deposition | Spreads a thin, uniform layer of metal powder | Creates the base for the new part layer |

| Preheating/Sintering | Electron beam lightly sinters the entire powder bed | Creates a supportive, conductive "cake" |

| Selective Melting | High-power beam melts powder following the CAD model | Fuses material to build the part geometry |

| Repetition | Platform lowers, and the cycle repeats | Builds the part layer-by-layer to completion |

Ready to harness the power of advanced metal 3D printing for your lab?

At KINTEK, we specialize in providing the high-performance lab equipment and consumables you need to push the boundaries of materials science and manufacturing. Whether you're exploring additive manufacturing for aerospace components or medical implants, our expertise can help you achieve superior results with stress-free, fully dense parts.

Contact our experts today to discuss how our solutions can support your specific laboratory and production goals.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Lab-Scale Vacuum Induction Melting Furnace

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What are the different types of sieving machines? Choose the Right Motion for Your Material

- What are the components of a sieving machine? Unlock the Anatomy of Precision Particle Separation

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What is the use of vibrating sieve machine? Achieve Precise Particle Size Analysis for Your Lab

- What is the principle of sieving machine? Achieve Accurate Particle Size Separation