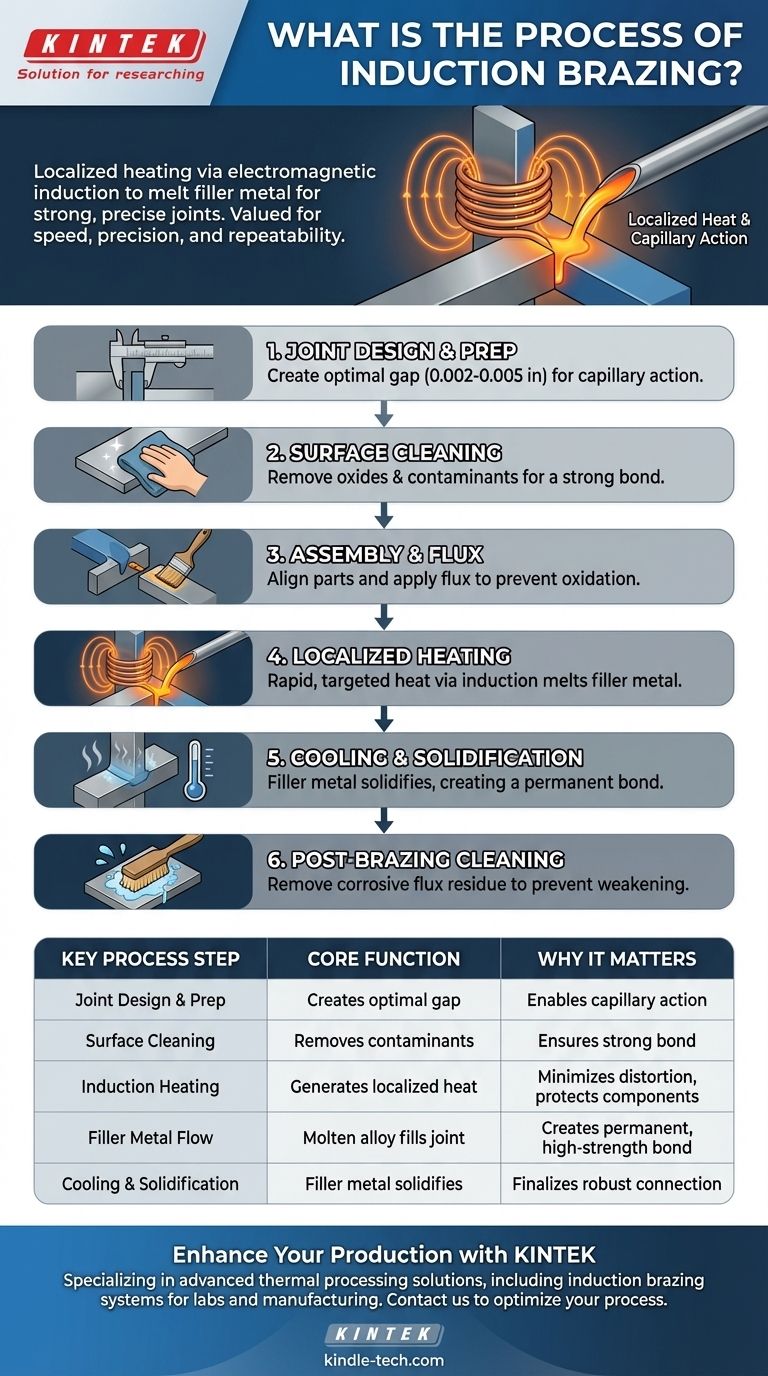

At its core, induction brazing is a process that uses electromagnetic induction to generate highly localized heat in conductive materials. This heat melts a filler metal with a lower melting point than the base parts, which then flows into a joint via capillary action and solidifies upon cooling, creating a strong metallurgical bond. The process is valued for its speed, precision, and repeatability.

The critical insight is that induction brazing is not about heating the entire assembly, but about generating rapid, targeted heat precisely where the joint is located. This makes it an exceptionally efficient and controllable method for high-volume manufacturing and joining heat-sensitive components.

The Principles Behind Induction Brazing

To understand the process, you must first grasp the two core technologies at play: induction heating and brazing.

How Induction Heating Works

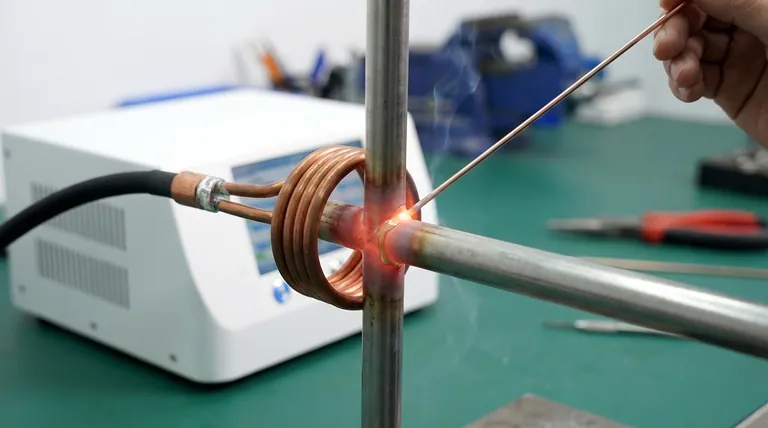

Induction heating uses a high-frequency alternating current passed through a copper induction coil. This creates a powerful, oscillating magnetic field around the coil.

When a conductive part (like steel or copper) is placed within this field, the magnetic field induces circular electrical currents within the metal, known as eddy currents.

The inherent electrical resistance of the material fights against these eddy currents, generating precise and rapid heat. It is a non-contact method that heats the part from within.

The Role of the Filler Metal and Capillary Action

Brazing relies on a filler metal (or braze alloy) with a melting point that is lower than the base materials being joined.

When the assembly is heated to the filler metal's melting temperature, the liquid alloy is drawn into the tight gap between the two base parts through a phenomenon called capillary action.

Upon cooling, the filler metal solidifies, forming a permanent, robust joint that is often as strong or stronger than the base materials themselves.

The Step-by-Step Induction Brazing Process

While the heating method is unique, the fundamental steps for preparing and executing a quality braze are universal.

Step 1: Joint Design and Preparation

The success of any brazed joint begins with its design. The gap between the parts must be carefully controlled—typically between 0.002 and 0.005 inches—to facilitate proper capillary action.

Step 2: Surface Cleaning

The surfaces of the joint must be meticulously cleaned. Any oxides, oils, or contaminants will prevent the filler metal from properly wetting the surfaces and flowing into the joint, resulting in a weak or failed bond.

Step 3: Assembly and Flux Application

The clean parts are assembled, sometimes using fixtures to maintain alignment and the correct gap. A flux is then applied to the joint area.

The flux acts as a chemical cleaner during heating, removing any oxides that form and protecting the area from atmospheric oxidation, which allows the molten braze alloy to flow freely.

Step 4: Localized Heating with Induction

The assembled joint is placed within or near the induction coil. The power supply is activated, generating the magnetic field and rapidly heating the joint area to the filler metal's melting point.

This step is typically very fast, often taking only a few seconds. The operator or an automated system introduces the filler metal, which melts and is instantly pulled into the joint.

Step 5: Cooling and Solidification

Once the joint is filled, the induction power is turned off. The assembly cools, and the filler metal solidifies, creating a permanent metallurgical bond between the components.

Step 6: Post-Brazing Cleaning

The final step is to clean the assembly to remove any remaining flux residue. Flux is corrosive, and if left on the part, it can weaken the joint and damage the base material over time.

Understanding the Trade-offs

Induction brazing is a powerful tool, but it is not the right solution for every application. Understanding its advantages and limitations is critical for proper process selection.

Key Advantages

The primary benefit of induction brazing is its speed and efficiency. Heating cycles are measured in seconds, making it ideal for high-volume, automated production lines.

Because the heat is highly localized, the rest of the assembly remains cool. This minimizes part distortion and protects heat-sensitive components located away from the joint. This is a major advantage over furnace brazing, which heats the entire part.

Finally, the process is extremely repeatable. Once the parameters (power, time, coil position) are set, an induction system can produce identical joints thousands of times with minimal variation.

Key Limitations

The main limitation is geometry. The induction coil must be able to be placed near the joint area, which can be challenging for complex or hard-to-reach joints.

The initial capital investment for induction heating equipment can also be higher than for a simple torch or furnace setup, though this is often offset by higher throughput and lower labor costs in production environments.

Making the Right Choice for Your Application

Selecting the correct brazing method depends entirely on your project's specific goals.

- If your primary focus is high-volume production and speed: Induction brazing is the ideal choice due to its rapid, repeatable heating cycles.

- If your primary focus is joining heat-sensitive components: The localized heating of induction prevents damage to the rest of the assembly.

- If your primary focus is creating a single, flawless joint in a controlled environment: Vacuum brazing may be a better option as it is fluxless and creates exceptionally clean joints.

- If your primary focus is processing large batches of non-sensitive parts simultaneously: Furnace brazing offers a practical and cost-effective method for bulk processing.

Ultimately, choosing induction brazing is a decision for precision and speed, trading geometric flexibility for unparalleled control and efficiency.

Summary Table:

| Key Process Step | Core Function | Why It Matters |

|---|---|---|

| Joint Design & Prep | Creates optimal gap (0.002-0.005 in) | Enables capillary action for filler metal flow |

| Surface Cleaning | Removes oxides and contaminants | Ensures strong metallurgical bond formation |

| Induction Heating | Generates localized, rapid heat via electromagnetic field | Minimizes part distortion; protects heat-sensitive areas |

| Filler Metal Flow | Molten alloy is drawn into the joint by capillary action | Creates a permanent, high-strength bond |

| Cooling & Solidification | Filler metal solidifies in the joint | Finalizes the robust, leak-tight connection |

Ready to enhance your production line with the speed and precision of induction brazing?

KINTEK specializes in advanced thermal processing solutions, including induction brazing systems tailored to your laboratory and manufacturing needs. Our expertise ensures you achieve stronger joints, higher throughput, and superior process control.

Contact our experts today to discuss how our lab equipment and consumables can optimize your metal joining processes.

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- High Performance Laboratory Freeze Dryer

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is the temperature of induction heating process? Unlock Precise Control from Gentle Warming to 1800°C+

- What materials can be used for induction heating? A Guide to Efficient and Effective Material Selection

- What are the advantages of induction casting? Superior Speed, Control, and Purity for High-Performance Metals

- What are the disadvantages of inductive heating? High Cost and Material Limitations Explained

- What are the applications of induction and dielectric heating? Choose the Right Process for Your Material

- What are the different heating methods for brazing? A Guide to Choosing the Right Process

- What is the temperature for induction hardening? Achieve Precise Hardness Without Compromising Part Integrity

- What is the main frequency of an induction furnace? A Guide to Optimizing Melting & Heating