At its core, the process of ion beam deposition (IBD) is a high-precision thin-film coating method that operates within a vacuum. It uses a focused, high-energy beam of ions to physically knock atoms off a source material (called a "target"), which then travel and condense onto a separate surface (the "substrate") to form an exceptionally dense and high-quality film.

The defining characteristic of ion beam deposition is its separation of the ion source from the target material. This separation provides an unparalleled level of independent control over the energy, direction, and flux of ions, resulting in films with superior density, purity, and adhesion compared to other deposition techniques.

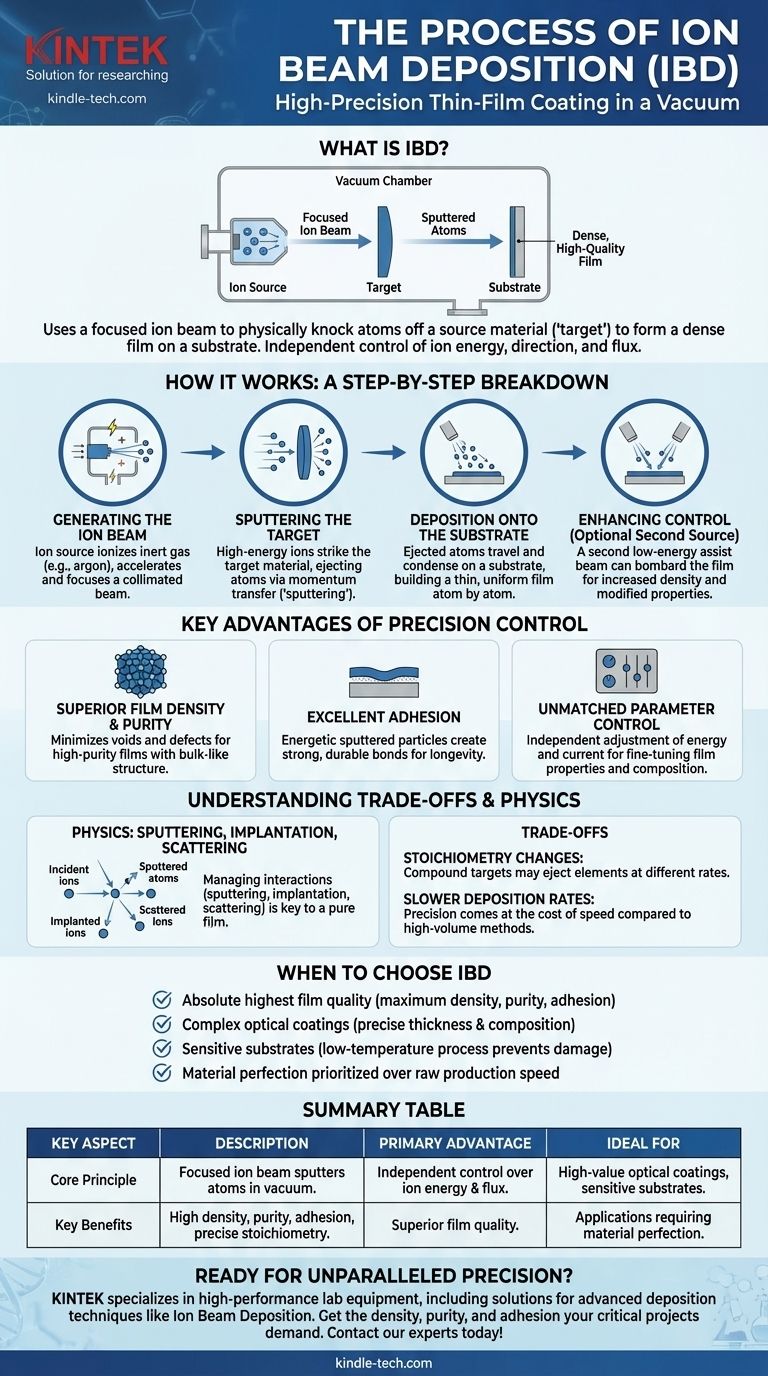

How Ion Beam Deposition Works: A Step-by-Step Breakdown

To understand IBD's advantages, it's essential to visualize its distinct stages. The entire process takes place in a high-vacuum chamber to prevent contamination.

Generating the Ion Beam

The process begins with an ion source, which is a specialized device that ionizes an inert gas, typically argon. This creates positively charged ions that are then extracted and accelerated by a high-voltage grid system, forming a well-defined, highly collimated beam.

Sputtering the Target

This high-energy ion beam is directed at the target, which is made of the material you wish to deposit. When the ions strike the target, they transfer their momentum to the target's atoms, a process known as sputtering. This collision has enough force to eject or "sputter" atoms from the target's surface.

Deposition onto the Substrate

The sputtered atoms travel in a straight line from the target and condense onto the substrate, which is strategically placed nearby. Atom by atom, this process builds a thin, uniform, and tightly bonded film on the substrate's surface.

Enhancing Control with a Second Source

In more advanced setups, a second ion source can be aimed directly at the substrate. This "assist beam" bombards the growing film with low-energy ions, further compacting the deposited material. This increases film density, modifies internal stress, and improves optical or mechanical properties.

The Key Advantages of Precision Control

The unique architecture of IBD is directly responsible for its primary benefits. Because the ion beam's characteristics can be managed independently from the material deposition, engineers gain precise control over the final film.

Superior Film Density and Purity

The energy imparted by the ions creates a film with a dense, almost bulk-like structure. This minimizes voids and defects, leading to higher purity and improved performance, particularly in optical and electronic applications.

Excellent Adhesion

The energetic nature of the sputtered particles promotes a strong, tenacious bond between the thin film and the substrate material. This adhesion is critical for the durability and longevity of the coating.

Unmatched Parameter Control

The energy and current of the ion beam can be adjusted independently. This allows for fine-tuning the deposition rate and the properties of the resulting film, such as its crystal structure and composition (stoichiometry), with a level of precision other methods cannot match.

Understanding the Trade-offs and Physics

While powerful, IBD is not a universal solution. Understanding its underlying mechanics and limitations is crucial for making an informed decision.

Sputtering, Implantation, and Scattering

The interaction between the ion beam and the target involves three key events. Sputtering is the desired outcome. However, some ions may embed themselves into the film or target (implantation), and others may bounce off the surface (scattering). Managing these effects is key to achieving a pure film.

Potential for Changes to Stoichiometry

When sputtering a compound target (one made of multiple elements), the elements may be ejected at slightly different rates. This can alter the chemical composition of the final film. While IBD offers tools to control this, it is a factor that must be carefully managed.

Slower Deposition Rates

The precision and control of IBD often come at the cost of speed. Its deposition rates are typically lower than high-volume techniques like magnetron sputtering. This makes it ideal for high-value applications where quality is more important than throughput.

When to Choose Ion Beam Deposition

Your final choice depends entirely on the requirements of your specific application.

- If your primary focus is the absolute highest film quality: IBD is the superior choice for achieving maximum density, purity, and adhesion in critical applications.

- If your primary focus is complex optical coatings: The precise, independent control over film thickness and composition makes IBD ideal for manufacturing advanced optical filters and mirrors.

- If your primary focus is sensitive substrates: IBD is a low-temperature process, which prevents thermal damage to delicate materials like polymers or pre-existing electronic components.

- If your primary focus is high-volume, low-cost production: You may need to weigh the superior quality of IBD against the faster deposition rates offered by alternative methods.

Ultimately, choosing ion beam deposition is a decision to prioritize precision and material perfection over raw production speed.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Uses a focused ion beam to sputter atoms from a target onto a substrate in a vacuum. |

| Primary Advantage | Independent control over ion energy and flux for superior film quality. |

| Key Benefits | High film density, excellent purity, strong adhesion, precise stoichiometry control. |

| Ideal For | High-value optical coatings, sensitive substrates, applications requiring material perfection. |

Ready to achieve unparalleled precision in your thin-film applications? KINTEK specializes in high-performance lab equipment, including solutions for advanced deposition techniques like ion beam deposition. Our expertise ensures you get the density, purity, and adhesion your critical projects demand. Contact our experts today to discuss how we can support your laboratory's specific needs with reliable equipment and consumables.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- High Performance Laboratory Freeze Dryer

People Also Ask

- What is the difference between MOCVD and MOVPE? They Are the Same Process

- How can the selective coating capability of the CVD process be enhanced? Precision Laser-Enhanced Deposition Guide

- What is the principle of DC sputtering? A Guide to Thin Film Deposition for Conductive Coatings

- How does a coating form CVD? Master the Chemical Reaction for Superior Thin Films

- What is chemical vapor deposition method of nanomaterials? Build Atom-by-Atom with Precise Control

- What is meant by chemical vapour deposition? A Guide to High-Purity Thin Film Growth

- What is thin film deposition in semiconductor manufacturing? Build Advanced Chips with Atomic Precision

- What is the general process of Chemical Vapor Deposition (CVD)? Master High-Performance Thin-Film Growth