At its core, the PACVD process is a method for depositing high-performance thin films onto a surface at relatively low temperatures. Unlike traditional Chemical Vapor Deposition (CVD), which relies on extreme heat to trigger chemical reactions, Plasma-Assisted Chemical Vapor Deposition (PACVD) uses an energized gas, or plasma, to activate the process. This fundamental difference allows for the coating of materials that would be damaged or destroyed by high-temperature methods.

The central innovation of PACVD is its use of plasma as an energy source. This allows for the formation of dense, durable, and highly adherent coatings at temperatures low enough to be compatible with heat-sensitive substrates like plastics, aluminum, and certain steels.

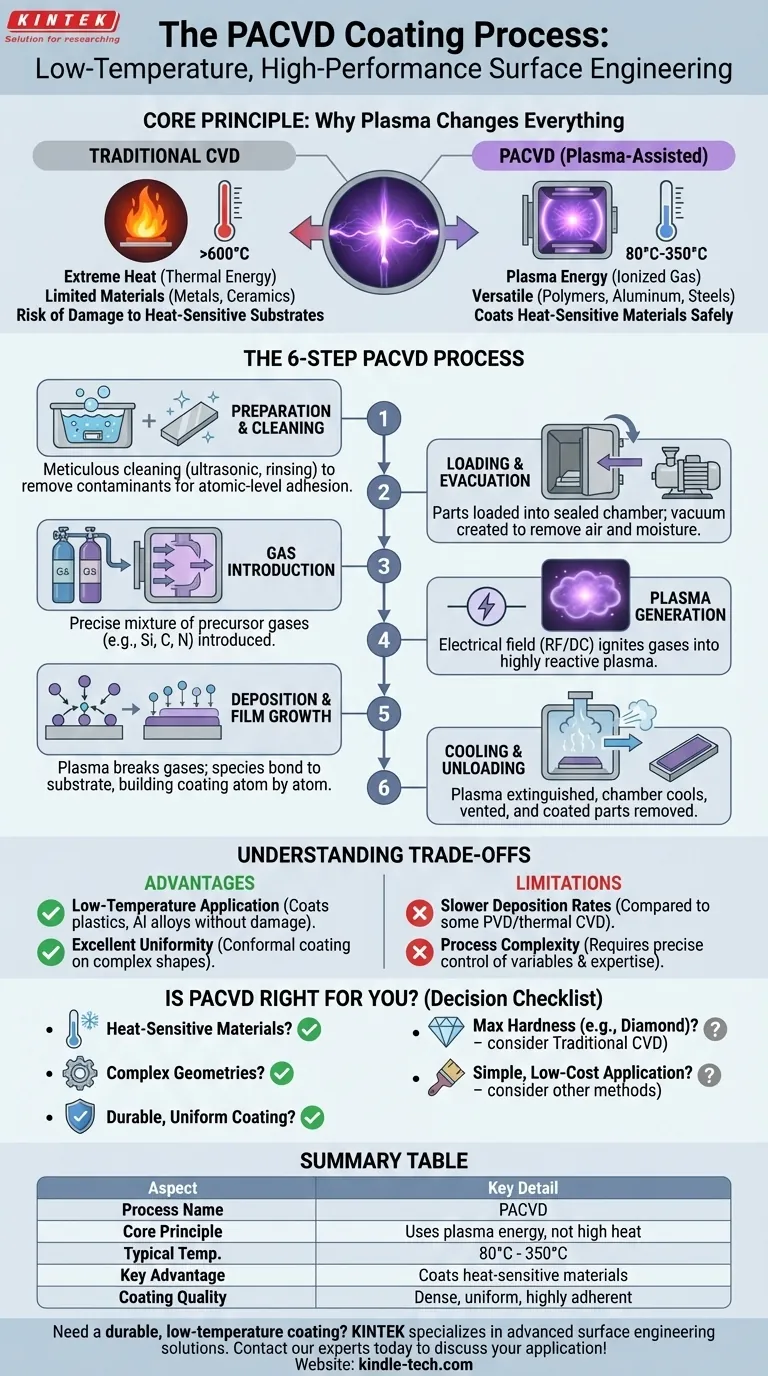

The Core Principle: Why Plasma Changes Everything

Traditional coating methods often present a difficult choice between performance and material compatibility. PACVD was developed to solve this problem by fundamentally changing how the coating reaction is powered.

Limitations of Traditional CVD

Standard Chemical Vapor Deposition (CVD) requires very high temperatures, often exceeding 600°C (1112°F). This heat provides the necessary thermal energy to break down precursor gases and form a coating on a substrate's surface.

However, these extreme temperatures limit the types of materials that can be coated, excluding most polymers, certain alloys, and tempered components whose properties would be ruined.

The Role of Plasma as an Energy Source

PACVD creates a low-pressure vacuum environment and then introduces an electrical field to excite the precursor gases into a plasma state. This plasma is a highly reactive mixture of ions, electrons, and neutral particles.

The intense energy within the plasma is sufficient to break down the gas molecules and initiate the chemical reactions needed for deposition. It effectively replaces the need for extreme thermal energy.

Key Benefits: Versatility and Quality

By using plasma instead of high heat, PACVD processes can operate at much lower temperatures, typically between 80°C and 350°C. This opens the door to coating a vast range of heat-sensitive materials.

Furthermore, the plasma environment often leads to coatings with excellent adhesion, high density, and superior uniformity, even on complex shapes.

The Step-by-Step PACVD Process

The PACVD process is a precise, multi-stage operation that takes place entirely within a sealed vacuum chamber. Each step is critical to the quality of the final coating.

Step 1: Substrate Preparation and Cleaning

This is arguably one of the most critical stages. The substrate (the part to be coated) must be meticulously cleaned to ensure proper coating adhesion.

This multi-step process often includes ultrasonic cleaning, rinsing, and drying to completely remove oils, lubricants, dust, and any other surface contaminants. An atomically clean surface is the foundation for a successful coating.

Step 2: Loading and Chamber Evacuation

Once cleaned, the parts are carefully loaded into the PACVD chamber on specialized fixtures. The chamber is then sealed and powerful pumps create a high-vacuum environment, removing virtually all air and residual moisture.

Step 3: Introduction of Precursor Gases

With the vacuum established, a precise mixture of precursor gases is introduced into the chamber. These gases contain the chemical elements that will ultimately form the desired coating layer (e.g., silicon, carbon, nitrogen).

Step 4: Plasma Generation

An electrical field, typically radio frequency (RF) or direct current (DC), is applied within the chamber. This energy ignites the precursor gases, transforming them into the glowing, energized plasma that characterizes the PACVD process.

Step 5: Deposition and Film Growth

Within the plasma, the precursor gas molecules are broken apart into highly reactive species. These species are then drawn to the substrate's surface, where they react and bond, building the coating one atomic layer at a time. This process continues until the desired coating thickness is achieved.

Step 6: Cooling and Unloading

After the deposition cycle is complete, the plasma is extinguished and the chamber is allowed to cool. The chamber is then vented back to atmospheric pressure, and the newly coated parts are carefully removed.

Understanding the Trade-offs of PACVD

Like any advanced technology, PACVD has a specific profile of strengths and weaknesses. Understanding these is key to determining if it is the right solution for a given problem.

Advantage: Low-Temperature Application

This is the defining benefit of PACVD. Its ability to coat polymers, aluminum alloys, and pre-hardened steels without altering their fundamental properties is a significant advantage over high-temperature alternatives.

Advantage: Excellent Uniformity

Because the precursor gas fills the entire chamber before being activated, PACVD can produce highly conformal coatings that cover complex geometries and internal surfaces more effectively than line-of-sight processes like PVD (Physical Vapor Deposition).

Limitation: Slower Deposition Rates

Generally, PACVD processes can have lower deposition rates compared to some PVD or thermal CVD techniques. This can make it less suitable for applications requiring extremely thick coatings or very high throughput.

Limitation: Process Complexity

PACVD systems are sophisticated and require precise control over numerous variables, including gas mixture, pressure, power, and temperature. This complexity can translate to higher equipment costs and a need for specialized operational expertise.

Is PACVD the Right Choice for Your Application?

Choosing the correct coating technology requires aligning its capabilities with your specific project goals.

- If your primary focus is coating heat-sensitive materials: PACVD is one of the best technologies available, offering hard, durable coatings for polymers, aluminum, and tempered components.

- If your primary focus is achieving a highly conformal coating on complex shapes: PACVD's gas-based nature provides a distinct advantage over line-of-sight methods, ensuring more uniform coverage.

- If your primary focus is maximum hardness or wear resistance on a temperature-stable material: Traditional high-temperature CVD might offer harder coatings (like diamond), while certain PVD technologies may provide higher performance for specific cutting tool applications.

- If your primary focus is minimizing cost for a simple application: Simpler coating methods like electroplating or painting may be more cost-effective if the advanced properties of a PACVD film are not required.

Ultimately, understanding the fundamentals of the PACVD process empowers you to make an informed decision based on your unique material and performance requirements.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Name | Plasma-Assisted Chemical Vapor Deposition (PACVD) |

| Core Principle | Uses plasma energy instead of high heat to deposit coatings |

| Typical Temperature Range | 80°C - 350°C (176°F - 662°F) |

| Key Advantage | Coats heat-sensitive materials (plastics, aluminum) |

| Coating Quality | Dense, uniform, and highly adherent films |

Need a durable, low-temperature coating for your heat-sensitive components?

KINTEK specializes in advanced lab equipment and consumables for surface engineering. Our expertise can help you determine if PACVD is the ideal solution for coating your polymers, aluminum alloys, or complex parts. We provide the technology and support to enhance your product's performance and longevity.

Contact our experts today to discuss your specific application requirements!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition