Waste tire pyrolysis is a thermochemical process that converts waste tires into valuable products such as fuel oil, carbon black, steel wire, and gas. The process involves heating the tires in an oxygen-free environment to break down the rubber into its constituent components. The key steps include feeding the tires into a reactor, heating them to induce depolymerization, condensing the resulting gases into oil, and collecting the solid residues. The process is environmentally friendly and economically beneficial, as it recycles waste tires into usable resources.

Key Points Explained:

-

Introduction to Waste Tire Pyrolysis:

- Waste tire pyrolysis is a process that thermally decomposes waste tires in the absence of oxygen to produce useful by-products such as fuel oil, carbon black, steel wire, and gas.

- This process is an effective way to recycle waste tires, reducing environmental pollution and generating valuable resources.

-

Preparation of Waste Tires:

- Tire Removal and Shredding: Waste tires are first collected and shredded into smaller pieces to facilitate the pyrolysis process. Shredding increases the surface area, allowing for more efficient heating and decomposition.

- Magnetic Separation: After shredding, the tires undergo magnetic separation to remove steel wires, which are then collected as a by-product.

-

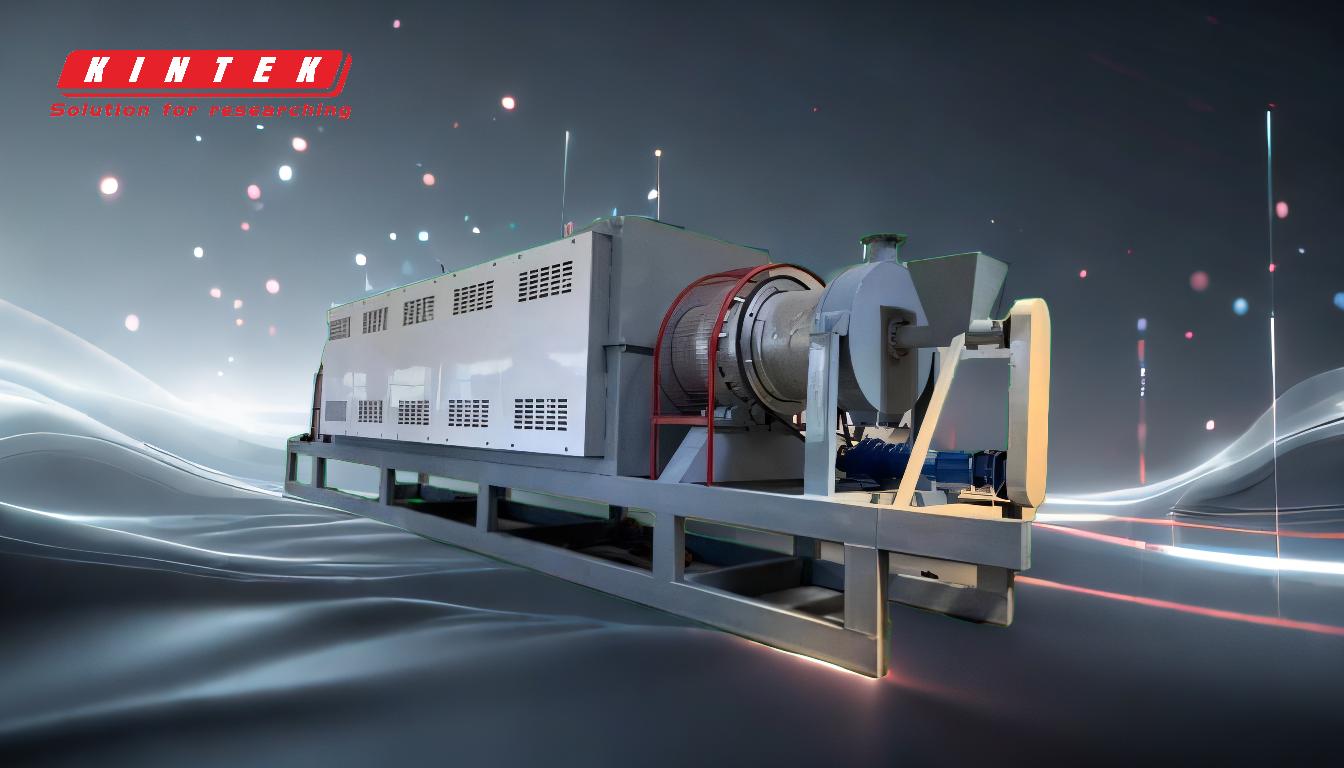

Feeding Tires into the Reactor:

- The shredded tires are fed into a pyrolysis reactor, which is a sealed vessel designed to withstand high temperatures and pressures.

- The reactor is placed inside a furnace, and oxygen is evacuated to create an oxygen-free environment, which is crucial for the pyrolysis process.

-

Heating and Depolymerization:

- The reactor is heated to a temperature range of 300-700°C, depending on the desired end products. This heating causes the rubber's main chain to crack into smaller molecules, including monomers, biopolymers, and fragments.

- The depolymerization process typically runs for 3-5 hours, during which the rubber breaks down into various hydrocarbons.

-

Condensation and Separation of By-Products:

- Condensation of Pyrolysis Oil: The vaporized gases produced during depolymerization are passed through a heat exchanger, where they are condensed into liquid pyrolysis oil. This oil can be used for heating, power generation, or further refining into fuels.

- Non-Condensable Gas Treatment: The non-condensable gases, primarily composed of methane, ethane, and other hydrocarbons, are desulfurized and cleaned before being stored in a gas pressure tank. These gases can be used as fuel for the pyrolysis process itself or for other industrial applications.

-

Collection of Solid Residues:

- Carbon Black: After the pyrolysis process, the solid residue left in the reactor is primarily carbon black, which can be used as a reinforcing agent in rubber products, as a pigment, or in the production of inks and coatings.

- Steel Wire: The steel wires removed during the magnetic separation step are collected and can be recycled for use in various industrial applications.

-

Continuous Process and Automation:

- Modern pyrolysis plants often operate on a continuous basis, with automated systems for feeding, heating, cracking, heat exchange, and slag discharge. This continuous operation increases efficiency and reduces labor costs.

- The process is designed to be energy-efficient, with the heat generated during pyrolysis often used to sustain the reaction, reducing the need for external energy sources.

-

Environmental and Economic Benefits:

- Environmental Benefits: Waste tire pyrolysis reduces the volume of waste tires in landfills, decreases the risk of tire fires, and minimizes the release of harmful chemicals into the environment. The process also reduces the demand for virgin materials by recycling waste into valuable products.

- Economic Benefits: The by-products of pyrolysis, such as fuel oil, carbon black, and steel wire, have significant market value. The process provides a sustainable and profitable way to manage waste tires, creating economic opportunities for businesses and communities.

-

Variability in Product Composition:

- The composition of the end products (fuel oil, carbon black, gas, and steel wire) can vary depending on factors such as the pyrolysis method, temperature, and the type of tires used. For example, higher temperatures may produce more gas and less oil, while lower temperatures may yield more oil and less gas.

- The quality of the carbon black can also vary, with higher-quality carbon black being more valuable for industrial applications.

-

Applications of Pyrolysis Products:

- Pyrolysis Oil: Can be used directly as a fuel for heating or power generation, or further refined into diesel or gasoline. It can also be used as a feedstock for chemical production.

- Carbon Black: Used in the manufacturing of tires, rubber products, plastics, inks, and coatings. It is also used as a reinforcing agent in various industrial applications.

- Steel Wire: Recycled and used in the production of new steel products, reducing the need for virgin steel and lowering production costs.

- Non-Condensable Gas: Used as a fuel source for the pyrolysis process itself or for other industrial processes, providing a sustainable energy source.

In conclusion, waste tire pyrolysis is a complex but highly effective process for recycling waste tires into valuable resources. The process involves several key steps, including tire preparation, depolymerization, condensation, and the collection of by-products. The resulting products have a wide range of applications, making pyrolysis an environmentally friendly and economically viable solution for managing waste tires.

Summary Table:

| Step | Description |

|---|---|

| Tire Preparation | Shredding and magnetic separation to remove steel wires. |

| Feeding into Reactor | Tires are fed into a sealed, oxygen-free reactor for pyrolysis. |

| Heating Process | Reactor heated to 300-700°C to break down rubber into hydrocarbons. |

| Condensation | Gases condensed into pyrolysis oil; non-condensable gases treated and stored. |

| Solid Residue Collection | Carbon black and steel wire collected for reuse. |

| Applications | Products used in fuel, rubber manufacturing, steel production, and more. |

Discover how waste tire pyrolysis can benefit your business—contact us today to learn more!