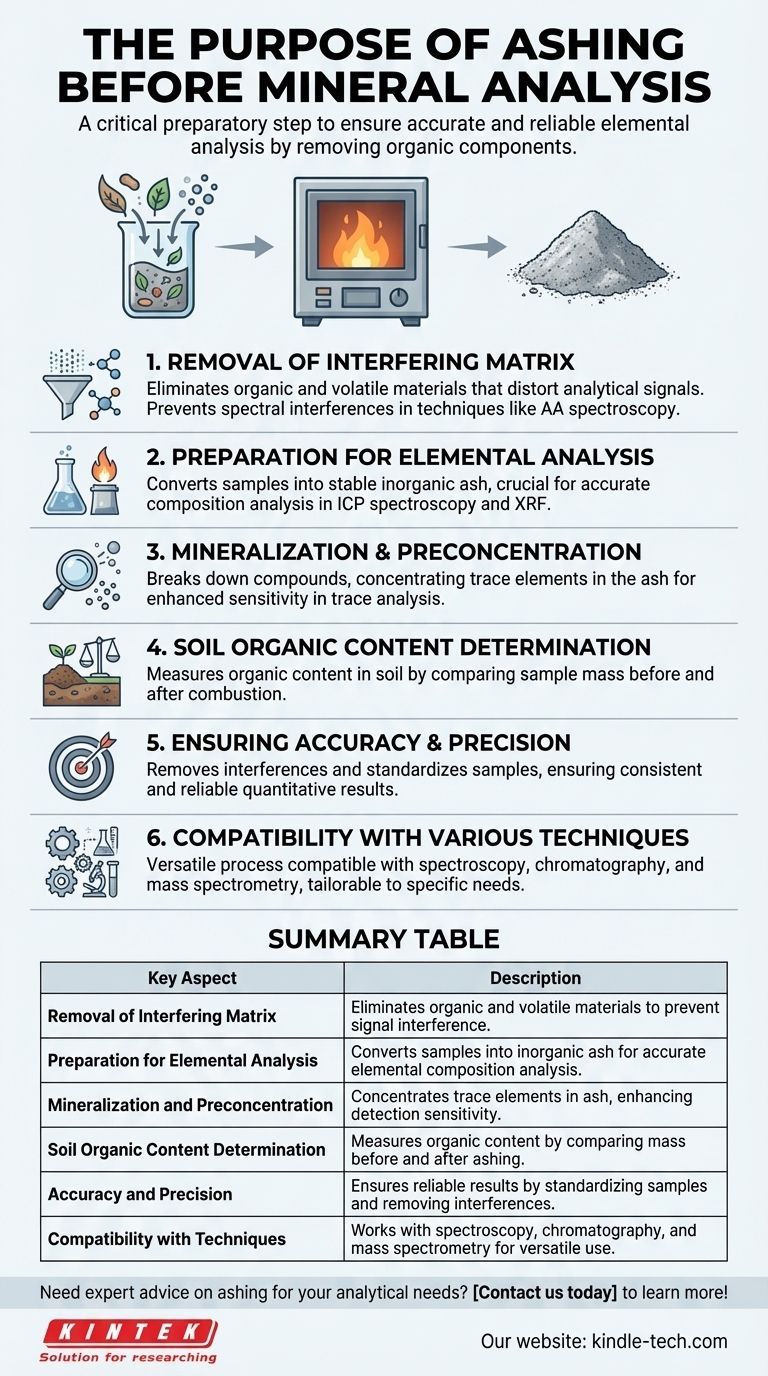

Ashing is a critical preparatory step in mineral analysis, particularly in analytical chemistry, where it serves to remove organic and volatile components from a sample, leaving behind noncombustible ash. This process is essential for accurate elemental analysis, as it eliminates matrix constituents that could interfere with the measurement of the analyte. By converting the sample into a more stable and analyzable form, ashing ensures that the subsequent analysis, such as spectroscopy or chromatography, yields precise and reliable results. It is also used in soil analysis to determine the organic content by comparing the mass before and after ashing.

Key Points Explained:

-

Removal of Interfering Matrix Constituents:

- Ashing is primarily used to eliminate organic and volatile materials that could interfere with the measurement of the analyte. These materials, if not removed, can distort the results of the analysis by either absorbing or emitting signals that overlap with those of the target elements.

- In techniques like graphite furnace atomic absorption (AA) spectroscopy, ashing removes matrix components that could otherwise cause background absorption or other spectral interferences, ensuring a cleaner signal for the analyte.

-

Preparation for Elemental Analysis:

- The ashing process converts the sample into a form that is more suitable for elemental analysis. By heating the sample to high temperatures, organic matter is burned off, leaving behind inorganic ash. This ash is then analyzed to determine its elemental composition.

- This step is crucial in techniques like inductively coupled plasma (ICP) spectroscopy or X-ray fluorescence (XRF), where the presence of organic materials could complicate the analysis or lead to inaccurate results.

-

Mineralization and Preconcentration:

- Ashing serves as a mineralization step, where organic compounds are broken down into simpler inorganic forms. This process is often used as a preconcentration step, where trace elements are concentrated in the ash, making them easier to detect and quantify.

- This is particularly important in trace analysis, where the concentration of the target elements is very low. By removing the bulk of the organic material, the relative concentration of the trace elements in the ash is increased, enhancing the sensitivity of the analysis.

-

Determination of Organic Content in Soil Analysis:

- In soil science, ashing is used to determine the organic content of soil samples. By comparing the mass of the sample before and after ashing, the proportion of organic material can be calculated. This is important for understanding soil composition and fertility.

- The loss of mass during ashing corresponds to the organic matter that has been combusted, providing a quantitative measure of the organic content in the soil.

-

Ensuring Accuracy and Precision in Analytical Results:

- By removing interfering substances and converting the sample into a more stable form, ashing helps to ensure that the analytical results are both accurate and precise. This is particularly important in quantitative analysis, where even small interferences can lead to significant errors.

- The ashing process also helps to standardize the sample, making it easier to compare results across different analyses or laboratories.

-

Compatibility with Various Analytical Techniques:

- Ashing is compatible with a wide range of analytical techniques, including spectroscopy, chromatography, and mass spectrometry. The process can be tailored to the specific requirements of the analysis, such as adjusting the temperature and duration of the ashing to ensure complete removal of organic material without degrading the inorganic components.

- This versatility makes ashing a valuable step in many different types of mineral and elemental analysis, from environmental testing to materials science.

In summary, ashing is a fundamental step in mineral analysis that ensures the accuracy and reliability of the results by removing interfering substances and preparing the sample for precise elemental analysis. Its application spans various fields, from environmental science to materials analysis, making it an indispensable tool in the analytical chemist's toolkit.

Summary Table:

| Key Aspect | Description |

|---|---|

| Removal of Interfering Matrix | Eliminates organic and volatile materials to prevent signal interference. |

| Preparation for Elemental Analysis | Converts samples into inorganic ash for accurate elemental composition analysis. |

| Mineralization and Preconcentration | Concentrates trace elements in ash, enhancing detection sensitivity. |

| Soil Organic Content Determination | Measures organic content by comparing mass before and after ashing. |

| Accuracy and Precision | Ensures reliable results by standardizing samples and removing interferences. |

| Compatibility with Techniques | Works with spectroscopy, chromatography, and mass spectrometry for versatile use. |

Need expert advice on ashing for your analytical needs? Contact us today to learn more!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement

- How to use a muffle furnace in a laboratory? A Step-by-Step Guide to Safe, Precise Thermal Processing

- What are the precautions of muffle furnace? Essential Safety Protocols for Your Lab

- What is the function of the sintering process in ceramic manufacturing? Achieve High Density and Structural Integrity