At its core, the purpose of a colloid mill is to create highly stable mixtures by drastically reducing the size of particles or droplets within a liquid. It functions as a high-shear rotor-stator mixer, designed to homogenize, disperse, and emulsify materials that would otherwise separate over time. This process ensures a product has a uniform consistency, texture, and long-term stability.

The immediate function of a colloid mill is particle size reduction. Its ultimate goal, however, is to produce a homogenous and stable emulsion or dispersion, which is critical for the quality, performance, and shelf-life of countless industrial and consumer products.

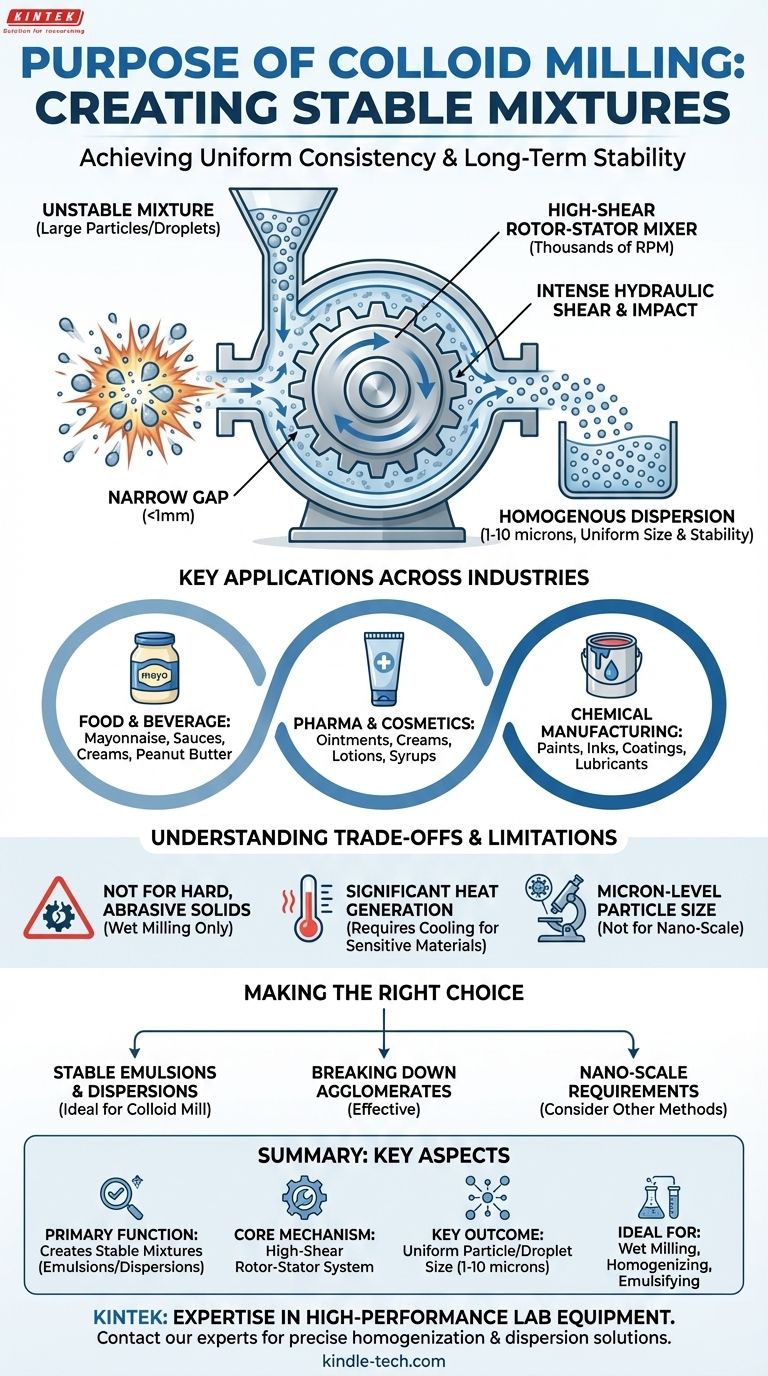

How a Colloid Mill Creates a Stable Mixture

A colloid mill achieves its results through intense mechanical force applied to a fluid. The entire process relies on a simple yet powerful engineering principle.

The Rotor-Stator Mechanism

The heart of the mill is composed of two primary components: a rotor that spins at extremely high speeds (often thousands of RPM) and a stationary outer casing called the stator.

The rotor and stator are precisely machined with complex patterns of slots or teeth. They are positioned incredibly close to each other, creating a very narrow gap, often less than a millimeter wide.

Intense Hydraulic Shear

As the product is fed into the mill, it is subjected to immense physical forces within this tiny gap. The high rotational speed of the rotor creates a massive velocity difference relative to the stationary stator.

This differential generates powerful hydraulic shear, which violently tears apart large solid particles or liquid droplets. The product is forced through the rotor-stator teeth, experiencing a combination of shear, impact, and high-frequency turbulence that breaks down its components.

From Unstable Mixture to Homogenous Dispersion

This intense energy input reduces particles or droplets down to a very small, uniform size, typically in the range of 1-10 microns.

By reducing the components to this microscopic scale and distributing them evenly throughout the liquid base, the colloid mill creates a stable mixture. The smaller particles are more easily suspended and are less susceptible to the forces of gravity or buoyancy that cause separation.

Key Applications Across Industries

The ability to create stable, uniform mixtures makes the colloid mill an essential piece of equipment in numerous sectors.

Food and Beverage Production

In food processing, texture and stability are paramount. Colloid mills are used to produce mayonnaise, salad dressings, sauces, and creams, ensuring oil and water phases do not separate. They are also used for grinding materials like peanuts into a smooth, homogenous peanut butter.

Pharmaceuticals and Cosmetics

For products applied to the skin or ingested, uniformity is critical for both safety and efficacy. Colloid mills are used to manufacture ointments, creams, lotions, and medicinal syrups, ensuring the active ingredients are evenly dispersed for consistent dosing and absorption.

Chemical Manufacturing

In the chemical industry, colloid mills are used to produce paints, inks, coatings, and lubricants. Their function is to uniformly disperse pigments, additives, and other solids into a liquid base, which is crucial for the final product's color consistency, performance, and stability.

Understanding the Trade-offs and Limitations

While highly effective, a colloid mill is not a universal solution. Understanding its limitations is key to using it correctly.

Not Designed for Hard, Abrasive Solids

A colloid mill excels at wet milling or dispersing solids that are already suspended in a liquid. It is not a grinder for hard, dry materials and can be damaged by highly abrasive particles.

Significant Heat Generation

The intense mechanical shear creates a substantial amount of heat as a byproduct. For heat-sensitive materials, such as some pharmaceuticals or food products, this can be a significant issue that may degrade the product. Many colloid mills are equipped with a cooling jacket to mitigate this effect.

Limits on Final Particle Size

A colloid mill is excellent for reducing particles to the micron level. However, for applications requiring nano-scale particles, other technologies like high-pressure homogenizers or media mills may be necessary, as they can achieve a finer degree of reduction.

Making the Right Choice for Your Goal

Selecting the correct processing equipment depends entirely on the desired characteristics of your final product.

- If your primary focus is creating a stable liquid-liquid emulsion (like a sauce or lotion): A colloid mill is an ideal and highly efficient choice for achieving the required droplet size and long-term stability.

- If your primary focus is dispersing a soft, pre-milled solid in a liquid (like a pigment or active ingredient): A colloid mill provides the necessary shear to break down agglomerates and ensure a smooth, homogenous final product.

- If your primary focus is achieving the finest possible particle size (nanometers) for a high-performance application: You should evaluate more specialized equipment, as a colloid mill may not meet the required level of fineness.

Ultimately, understanding the principle of high-shear rotor-stator milling empowers you to select the precise tool to guarantee your product's quality, consistency, and stability.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Creates highly stable mixtures (emulsions/dispersions) |

| Core Mechanism | High-shear rotor-stator system |

| Key Outcome | Uniform particle/droplet size (1-10 microns) |

| Main Industries | Food & Beverage, Pharmaceuticals, Cosmetics, Chemicals |

| Ideal For | Wet milling, homogenizing, emulsifying heat-sensitive materials (with cooling) |

Need to ensure your product's stability and uniformity?

KINTEK specializes in high-performance lab equipment, including colloid mills designed for precise homogenization and dispersion. Whether you're developing a new cosmetic cream, a stable food sauce, or a uniform pharmaceutical ointment, our expertise can help you achieve perfect consistency and extended shelf-life.

Contact our experts today to discuss your specific application and find the ideal colloid mill for your laboratory needs!

Visual Guide

Related Products

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Laboratory Micro Tissue Grinding Mill Grinder

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

People Also Ask

- What is the function of high-shear dispersion equipment in corona-resistant nanocomposites? Elevate Your Insulation

- What are the advantages of using a high-shear homogenizer for BED/GMA coatings? Achieve Superior Nano-Dispersion

- Why are stirring or homogenizing devices essential in phase inversion? Achieve Perfect Photocatalytic Membrane Dispersion

- What functions do laboratory centrifuges and high-shear homogenizers perform? Optimize Your Nano-Modified Composites

- How does a high-efficiency homogenizing mixer contribute to the preparation of Tobermorite and Xonotlite precursors?