In a bioreactor, the overlay's primary purpose is to control the gas composition in the headspace—the volume of gas above the liquid culture. This provides a non-invasive way to manage the concentration of dissolved gases like oxygen and carbon dioxide, which are critical for cell health, pH stability, and overall process success. It acts as a gentle, precise control layer that complements the more aggressive method of sparging gas directly through the culture.

The overlay is not just for adding gas; it is a strategic tool for decoupling gas supply from mechanical agitation. This allows you to fine-tune the cellular environment—particularly for controlling dissolved CO2 and managing pH—without introducing the damaging shear stress or foam associated with high sparging rates.

How an Overlay Works: Beyond Simple Gas Supply

To effectively use an overlay, you must understand its mechanism and how it differs from other gas exchange methods.

Defining the Headspace and Overlay

The headspace is the volume of gas between the surface of the liquid culture and the top of the bioreactor vessel.

An overlay is the controlled, continuous flow of a specific gas or gas mixture into this headspace. This flow flushes the existing atmosphere and maintains a desired gas composition at the liquid's surface.

The Mechanism of Gas Transfer

The overlay facilitates gas exchange through diffusion across the gas-liquid interface.

Molecules of gas (e.g., O2, CO2) in the headspace dissolve into the culture medium at the surface, driven by the difference in partial pressure between the two phases. The rate of this transfer depends on the surface area and the efficiency of mixing, which constantly renews the liquid at the surface.

Decoupling Gas Supply from Agitation

An overlay's key advantage is separating gas delivery from physical disruption. Sparging (bubbling gas through the liquid) is highly efficient for oxygen transfer but can create significant shear stress and foam, damaging sensitive cells.

The overlay provides a gentle alternative, allowing you to supply necessary gases without the physical impact of sparging.

Key Applications for an Overlay

The overlay is a versatile tool used to solve several common challenges in cell culture processes.

Precise pH Control via CO2 Management

This is one of the most critical applications. Most cell culture media use a bicarbonate buffer system to maintain stable pH.

The concentration of dissolved CO2 directly influences pH. By controlling the percentage of CO2 in the overlay gas, you can precisely regulate the dissolved CO2 and steer the culture's pH without the need for harsh liquid acid/base additions.

Supporting Shear-Sensitive Cell Lines

Mammalian, insect, and certain microbial cells are highly sensitive to the physical shear forces generated by bursting gas bubbles during sparging.

For these fragile cultures, an overlay provides a baseline level of O2 and CO2 exchange that is essential for viability, minimizing the cell damage that would occur with aggressive sparging.

Managing Foam

Excessive sparging is a primary cause of foam, which can clog exhaust filters, lead to contamination, and cause loss of product.

By reducing the reliance on high sparge rates, the use of an overlay directly mitigates foam formation, simplifying bioreactor operation and reducing process risk.

Creating Specific Atmospheric Conditions

For anaerobic or microaerophilic cultures, oxygen is toxic. The overlay is essential for purging oxygen from the headspace.

Continuously flushing the headspace with an oxygen-free gas, such as nitrogen (N2), ensures the strict atmospheric conditions required for these specialized processes are maintained.

Understanding the Trade-offs and Limitations

While powerful, the overlay is not a universal solution and has clear limitations that must be respected.

Lower Mass Transfer Rate

The single greatest limitation of an overlay is its relatively low mass transfer coefficient (kLa). The surface area of the liquid is vastly smaller than the cumulative surface area of countless bubbles produced by a sparger.

For this reason, an overlay alone cannot supply enough oxygen to support high-density cultures with significant oxygen demand. In these cases, it must be used in conjunction with sparging.

Slower Response Time

Because it relies on diffusion across a limited surface area, the effect of changing the overlay gas composition on the culture is much slower than with direct sparging.

This makes the overlay unsuitable for rapid, emergency interventions if, for example, dissolved oxygen levels were to crash suddenly.

Dependence on Mixing

The effectiveness of an overlay is highly dependent on good agitation within the vessel. The impeller must ensure constant surface renewal, bringing oxygen-depleted media from the bottom of the reactor to the surface to facilitate gas exchange. In poorly mixed reactors, the overlay's effect may be limited to the top layer of the culture.

Making the Right Choice for Your Process

Integrating an overlay into your control strategy depends entirely on your culture's specific needs and your primary process goals.

- If your primary focus is high-density culture with high oxygen demand: Rely on sparging for bulk oxygen supply, but use the overlay for fine-tuning pH with CO2 and managing foam.

- If your primary focus is growing shear-sensitive cells: Use the overlay as the primary method for gas exchange to minimize cell damage, supplementing with low-rate sparging only if necessary.

- If your primary focus is precise, non-invasive pH control: Use the overlay to deliver controlled amounts of CO2 to balance the bicarbonate buffer system without chemical additions.

- If your primary focus is an anaerobic or microaerophilic culture: Use the overlay to continuously flush the headspace with an oxygen-free gas mixture (like N2) to maintain the required environment.

Ultimately, viewing the overlay as a complementary control system to sparging—not a replacement—unlocks a more nuanced and effective approach to bioreactor management.

Summary Table:

| Key Function | Benefit | Consideration |

|---|---|---|

| Precise pH Control via CO2 | Non-invasive regulation using bicarbonate buffer system | Slower response time than direct sparging |

| Support for Shear-Sensitive Cells | Minimizes physical damage from bubble bursting | Lower oxygen transfer rate (kLa) |

| Foam Management | Reduces sparging-related foam and contamination risk | Requires good mixing for effective surface renewal |

| Anaerobic/Microaerophilic Cultures | Maintains oxygen-free headspace with gases like N2 | Not sufficient for high-density cultures alone |

Optimize Your Bioprocess with KINTEK Lab Equipment

Struggling with pH stability, cell viability, or foam control in your bioreactor runs? The strategic use of an overlay gas is key to gentler, more precise process control—especially for sensitive mammalian, insect, or microbial cultures.

At KINTEK, we specialize in supplying reliable bioreactors and lab equipment designed to help you implement advanced control strategies like overlay gassing. Our solutions support researchers and lab professionals in achieving higher yields and better process consistency.

Let us help you enhance your cell culture outcomes. Contact our experts today to discuss your specific bioreactor needs and discover the right equipment for your lab.

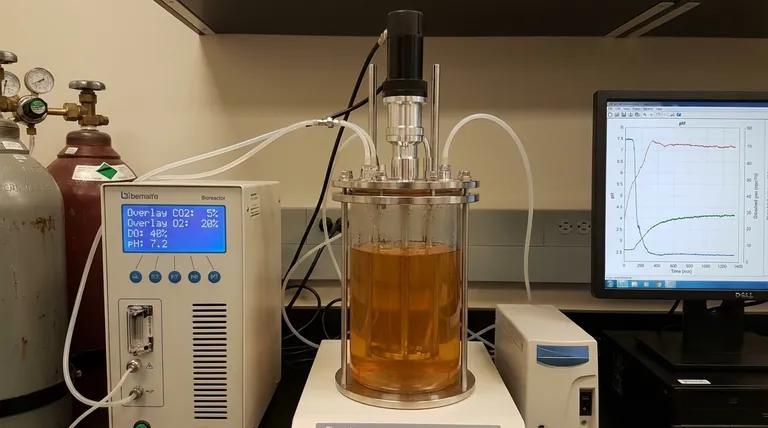

Visual Guide

Related Products

- Copper Foam

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- How does a jacketed laboratory reactor maintain process stability? Master Thermal Control in Electrochemistry

- Why Use a PTFE-Lined Stainless Steel Reactor for Boehmite Synthesis? Ensuring Purity in High-Pressure Environments

- What is a biochar reactor? Turn Waste into Valuable Carbon for Soil and Energy

- Why are nickel-based alloys like Inconel or Hastelloy required for SCW reactors? Ensure Durability in Extreme Environments

- Why are reactors and control systems critical for the chemical co-precipitation method? Precision for Magnetic Fluids

- What is the primary role of high-pressure reactors in H2 engine material testing? Ensuring Durability & HTHA Resistance

- Why is a laboratory continuous flow reactor preferred over a closed reactor? Optimize Methane Reforming Precision

- Why is a titanium alloy reactor used for 121°C chemical cleaning? Ensure Pure Data in High-Temp Corrosion Tests