In essence, a pelletizing machine is a device designed to compress or form fine, often low-density, materials into small, uniform cylinders or spheres known as pellets. This process, technically called agglomeration, transforms materials like sawdust, agricultural waste, or animal feed ingredients into a dense, manageable, and more valuable form.

The fundamental purpose of pelletizing is not just to change a material's shape, but to radically improve its handling characteristics. It converts dusty, difficult-to-manage bulk materials into a standardized product with increased density, making it easier to transport, store, and use efficiently.

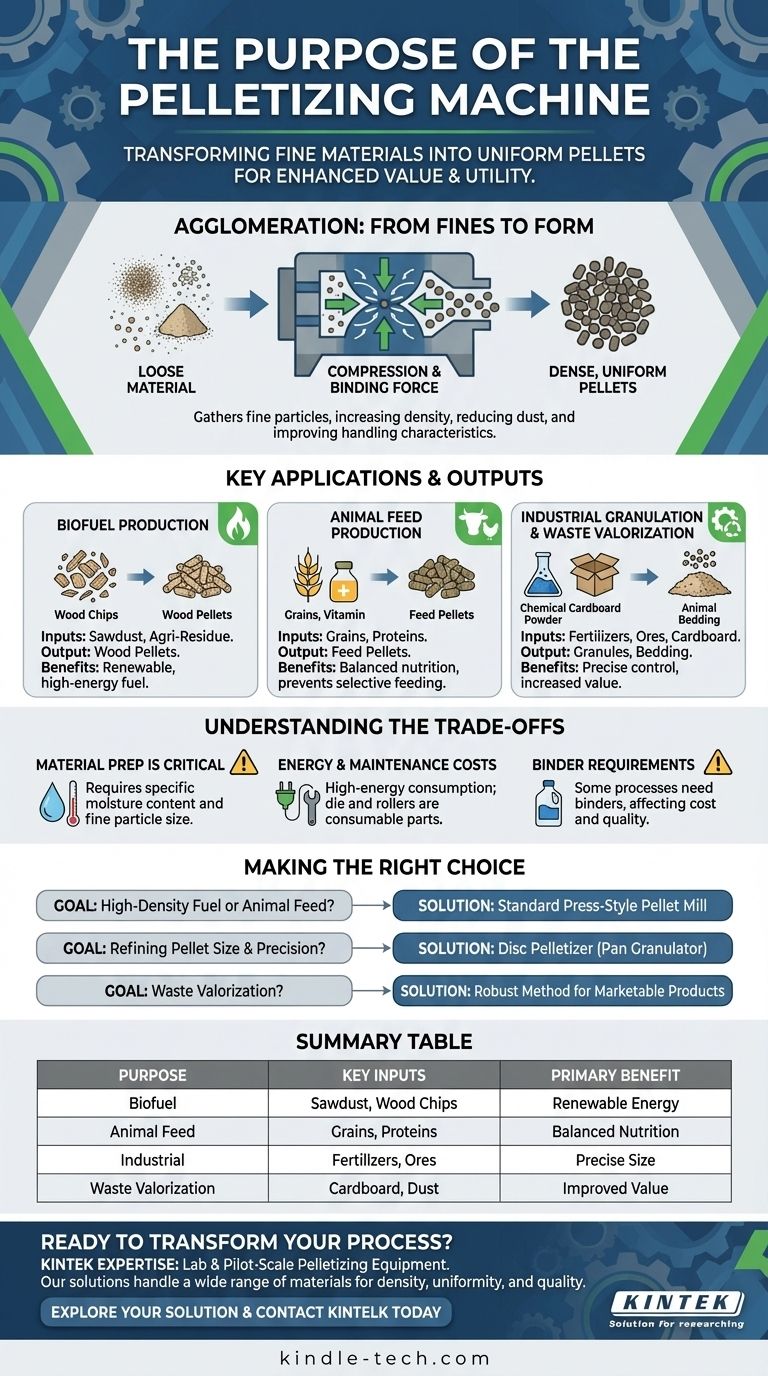

The Core Principle: Agglomeration

From Fines to Form

The underlying process of pelletizing is agglomeration. This involves gathering fine, solid particles and binding them together to create larger, more uniform elements.

Whether it's sawdust, grain dust, or mineral powders, the machine applies force, sometimes with heat or a binding agent, to cluster these particles into a durable, dense format.

Why This Matters

Converting loose material into pellets offers several critical advantages. It dramatically increases bulk density, allowing more material to be stored in a smaller space.

It also reduces dust, improving air quality and safety, and creates a uniform product that flows easily and can be used in automated systems for fuel or feed.

Key Applications and Outputs

Creating Biofuel

One of the most common applications is producing wood pellet fuel. A pellet machine takes waste materials like sawdust, wood chips, or agricultural residue and compresses them into high-energy pellets.

These pellets serve as an efficient, environmentally friendly fuel source for home heating stoves and industrial boilers, effectively turning waste into a renewable energy resource.

Producing Animal Feed

In agriculture, pelletizing machines are essential for creating livestock and poultry feed. They combine various nutritional ingredients, such as grains, proteins, and vitamins, into a single, compact pellet.

This ensures that each animal receives a consistent and balanced diet, prevents selective feeding, and makes the feed easier to handle and digest.

Specialized Industrial Uses

Beyond fuel and feed, pelletizing is used for other specific purposes. Materials like cardboard can be pelletized to create highly absorbent animal bedding.

In other industries, disc-style pelletizers are used to granulate fertilizers, ores, and other chemicals where precise control over pellet size and density is crucial.

Understanding the Trade-offs

Material Preparation is Critical

A pelletizing machine cannot process raw material in just any state. The input material must have a specific moisture content and a consistent, fine particle size to form a quality pellet.

Failing to properly prepare the material can lead to poor pellet quality, machine jams, and excessive wear on the equipment.

Energy and Maintenance Costs

The process of compression requires significant force, making pellet mills high-energy consumers. This is a primary operational cost to consider.

Furthermore, the key components that apply pressure, such as the die and rollers in a standard mill, are subject to intense friction and wear. They are consumable parts that require regular replacement, contributing to ongoing maintenance costs.

Binder Requirements

Some pelletizing processes, especially those using a disc granulator, require the addition of a binder to help the fine particles stick together. The cost and type of this binder can impact the final product's quality and overall production economics.

Making the Right Choice for Your Goal

Based on the desired outcome, the approach to pelletizing can differ significantly.

- If your primary focus is creating high-density fuel or animal feed: A standard press-style pellet mill is the most direct and common solution for these applications.

- If your primary focus is refining pellet size and characteristics with precision: A disc pelletizer (or pan granulator) offers greater control over the final product, vital for chemical or mineral processes.

- If your primary focus is waste valorization: Pelletizing provides a robust method to convert low-value waste streams like sawdust or agricultural residue into valuable, marketable products.

Ultimately, pelletizing is a transformative process that brings order, density, and value to otherwise unmanageable materials.

Summary Table:

| Purpose | Key Input Materials | Common Outputs | Primary Benefit |

|---|---|---|---|

| Biofuel Production | Sawdust, Wood Chips, Agri-Residue | Wood Pellets | Renewable, High-Energy Fuel |

| Animal Feed Production | Grains, Proteins, Vitamins | Feed Pellets | Balanced Nutrition, Easy Handling |

| Industrial Granulation | Fertilizers, Ores, Chemicals | Uniform Granules | Precise Size & Density Control |

| Waste Valorization | Cardboard, Dust, Powders | Bedding, Marketable Products | Improved Density & Value |

Ready to transform your material handling process?

Whether your goal is to produce efficient biofuel, create consistent animal feed, or valorize industrial waste, KINTEK's expertise in lab and pilot-scale pelletizing equipment can help you achieve it. Our solutions are designed to handle a wide range of materials, ensuring you get the density, uniformity, and quality you need.

Let's discuss your specific application and find the perfect pelletizing solution for your lab or operation.

Contact KINTELK today for a consultation to explore how our specialized equipment can bring efficiency and value to your projects.

Visual Guide

Related Products

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Powerful Plastic Crusher Machine

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- What is a pellet mill? Transform Powder into High-Density Pellets Efficiently

- What is a single punch tablet machine? The Essential Tool for Lab-Scale Tablet R&D

- What are the different types of pelletizers? A Guide to Choosing the Right Machine for Your Material

- What are pill presses used for? Transforming Powders into Precise Tablets for Medicine, Supplements, and More

- What are advantages of single punch tablet press machine? Maximize R&D Efficiency with Minimal Material

- What is the process of pelleting biomass? Transform Raw Biomass into High-Value, Energy-Dense Fuel

- What is the use of single punch tablet press? For Precise R&D and Small-Batch Tablet Production

- What are the different parts of a single punch tablet machine? The Core Components Explained