In essence, the PVD color process is a high-tech vacuum deposition method used to apply a very thin, yet extremely durable, colored film onto a material's surface. Unlike paint, this process doesn't add a separate layer of pigment. Instead, it creates a new, colored ceramic surface that is molecularly bonded to the original object, resulting in a finish that is highly resistant to wear, scratches, and corrosion.

The core purpose of PVD is not just to color an object, but to fundamentally transform its surface. By creating a ceramic compound at an atomic level, the process imparts a color that is an inseparable part of the material, offering superior durability compared to traditional coatings.

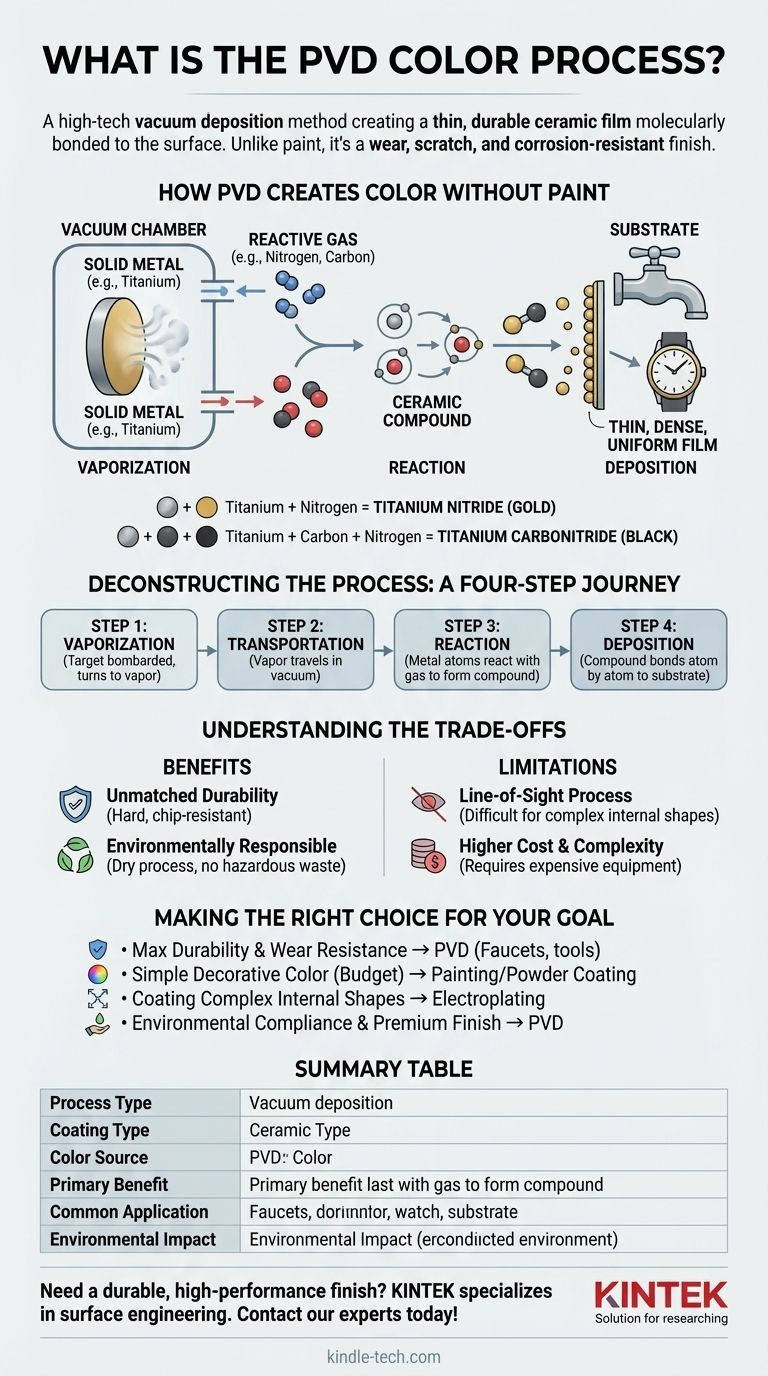

How PVD Creates Color Without Paint

The color you see from a PVD coating is not from a dye or pigment. It is the inherent, physical property of a specific ceramic compound that is formed and deposited onto the surface in a microscopic layer.

The Source of the Color

The process begins with a solid metal, such as titanium, zirconium, or chromium. This metal is vaporized inside a vacuum chamber.

Crucially, a precisely controlled reactive gas (like nitrogen, carbon, or oxygen) is also introduced. The vaporized metal atoms react with this gas to form a new ceramic compound, and it's this compound that possesses a specific, stable color.

For example, titanium reacting with nitrogen creates titanium nitride, which has a brilliant gold color. If it reacts with carbon and nitrogen, it forms titanium carbonitride, which is black.

Building the Film Atom by Atom

This newly formed ceramic compound travels through the vacuum and lands on the object being coated (the substrate). It builds up in an exceptionally thin, dense, and uniform layer, often just a few microns thick.

Because the film is so thin and uniform, it doesn't obscure the underlying texture of the material, preserving fine details like brushed or polished finishes.

Deconstructing the PVD Process: A Four-Step Journey

While the technology is complex, the process can be understood in four distinct stages that take place inside a high-vacuum chamber.

Step 1: Vaporization

The process starts with a solid block of the coating material, known as the "target." This target is bombarded with a high-energy source, such as a plasma arc or ion beam, which dislodges individual atoms and turns the solid material into a vapor.

Step 2: Transportation

These vaporized atoms travel from the target toward the object being coated. This happens in a near-perfect vacuum to ensure the atoms don't collide with air molecules or contaminants, which would disrupt the process and contaminate the final coating.

Step 3: Reaction

This is the critical stage for creating color. As the metal vapor travels, a carefully chosen reactive gas is introduced into the chamber. The metal atoms chemically react with the gas molecules to form the desired ceramic compound.

Step 4: Deposition

Finally, the newly formed ceramic compound deposits onto the surface of the substrate. This creates a strong molecular bond, building a dense and hard film, atom by atom, until the desired thickness and color are achieved.

Understanding the Trade-offs

PVD is a superior process for many applications, but it's essential to understand its specific advantages and limitations compared to traditional methods like electroplating or powder coating.

The Benefit: Unmatched Durability

PVD coatings are significantly harder and more resistant to wear, friction, and chemical attack than most other finishes. Because the coating is bonded at a molecular level, it won't chip, flake, or peel the way paint can.

The Benefit: Environmentally Responsible

The process is entirely dry and does not produce the hazardous chemical waste associated with traditional wet plating processes. This makes PVD a much cleaner and more environmentally friendly finishing technology.

The Limitation: A "Line-of-Sight" Process

The coating vapor travels in a straight line from the source to the substrate. This means it's difficult to evenly coat complex internal geometries or deeply recessed areas without sophisticated part-rotation systems.

The Limitation: Higher Cost and Complexity

PVD requires expensive vacuum chambers, high-purity target materials, and skilled operators. This results in a higher upfront cost compared to simpler processes like painting, making it best suited for products where performance and longevity are critical.

Making the Right Choice for Your Goal

Selecting a finish requires matching the process to the product's intended use and desired performance.

- If your primary focus is maximum durability and wear resistance: PVD is the superior choice for high-contact items like faucets, watches, tools, and industrial components.

- If your primary focus is a simple decorative color on a budget: Traditional methods like painting or powder coating are more cost-effective for surfaces that won't experience significant wear.

- If your primary focus is coating complex internal shapes: Electroplating may offer better coverage inside intricate parts, as its chemical bath is not restricted by line-of-sight.

- If your primary focus is environmental compliance and a premium finish: PVD is the leading choice, providing exceptional performance while avoiding hazardous waste streams.

By understanding the PVD process, you can choose a finish based on its fundamental properties, ensuring your product's surface performs exactly as intended.

Summary Table:

| Key Aspect | PVD Process Detail |

|---|---|

| Process Type | Vacuum deposition (Physical Vapor Deposition) |

| Coating Type | Thin ceramic film, molecularly bonded |

| Color Source | Reaction between metal vapor (e.g., Titanium) and gas (e.g., Nitrogen) |

| Primary Benefit | Extreme durability, scratch & corrosion resistance |

| Common Application | Faucets, watches, tools, industrial components |

| Environmental Impact | Dry process, no hazardous waste |

Need a durable, high-performance finish for your components? KINTEK specializes in advanced lab equipment and consumables for surface engineering and R&D. Our expertise can help you integrate PVD technology to achieve superior wear resistance and lasting color for your products. Contact our experts today to discuss your specific laboratory or manufacturing needs!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure