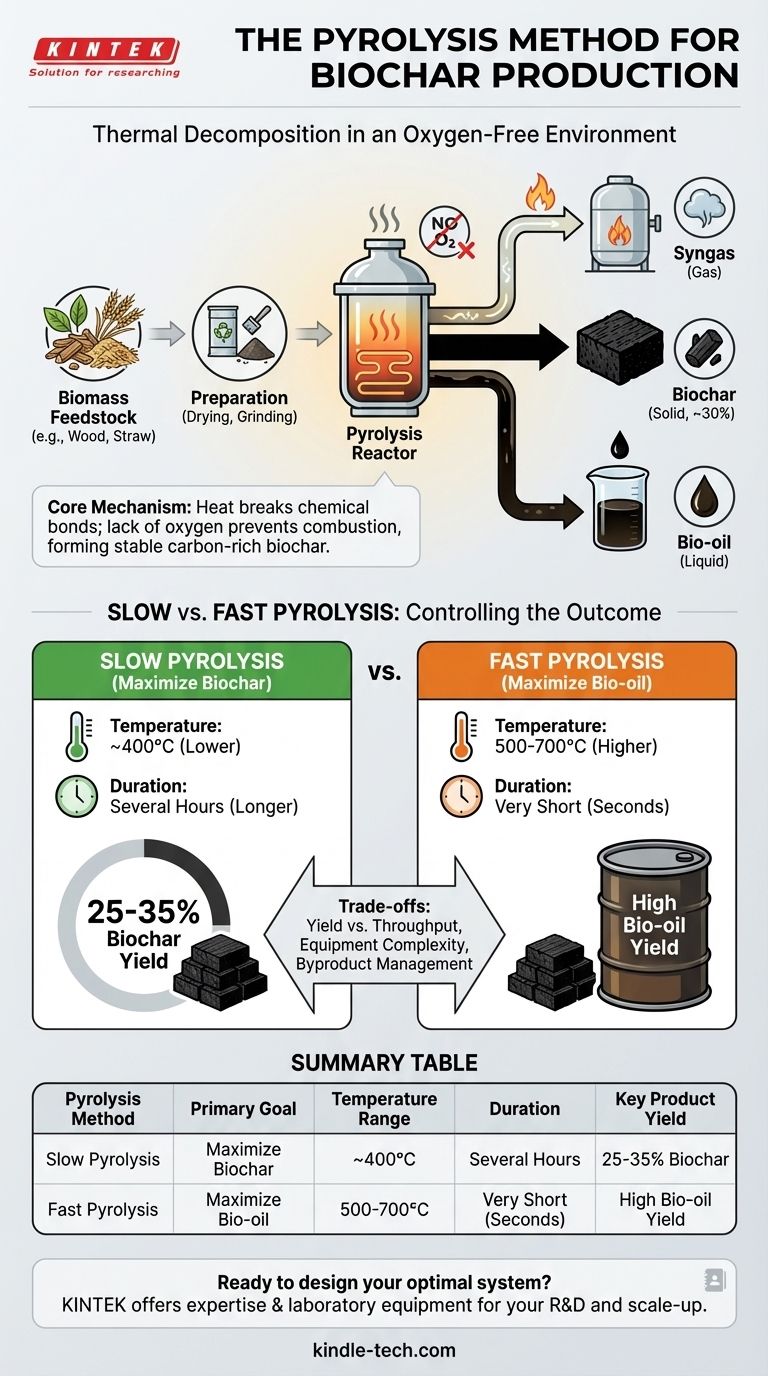

In essence, the pyrolysis method for biochar production is a process of thermal decomposition. It involves heating organic materials, known as biomass feedstock, to high temperatures in an environment with little to no oxygen. This lack of oxygen is critical, as it prevents the material from combusting and instead causes it to break down into a stable, carbon-rich solid (biochar), along with a liquid (bio-oil) and a gas (syngas).

The core principle is this: pyrolysis is not a single method, but a spectrum of processes. To maximize the yield of high-quality biochar, a specific technique called slow pyrolysis is used, which relies on lower temperatures and longer processing times to favor the creation of a solid char.

The Core Mechanism of Pyrolysis

Pyrolysis is fundamentally a chemical transformation driven by heat in an anaerobic (oxygen-free) setting. Understanding this mechanism is key to controlling the outcome of the process.

The Role of Heat and Oxygen

Heat provides the energy to break the complex chemical bonds within the biomass. Without oxygen, the material cannot burn. Instead, it thermally decomposes into simpler, more stable components.

The Input: Biomass Feedstock

The process begins with organic material, or feedstock. Common examples include pine wood, wheat straw, green waste, and even dried algae.

Before entering the pyrolysis reactor, this feedstock is typically prepared by drying to remove moisture and undergoing comminution (grinding or shredding) to create a uniform particle size.

The Outputs: Solids, Liquids, and Gases

Pyrolysis always produces three distinct products. The goal of the process determines which of these is optimized.

- Biochar (Solid): A stable, carbon-rich solid that is the primary target for biochar production.

- Bio-oil (Liquid): A dark, viscous liquid also known as pyrolysis oil or bio-crude.

- Syngas (Gas): A mixture of non-condensable gases, including hydrogen, carbon monoxide, and methane.

Slow vs. Fast Pyrolysis: Controlling the Outcome

The specific conditions of pyrolysis—primarily temperature and duration—dictate the proportion of the three outputs. This distinction is the most important factor in designing a production system.

Slow Pyrolysis for Biochar Production

This is the primary method for maximizing biochar yield. It is defined by lower temperatures and longer residence times.

- Temperature: Typically around 400°C.

- Duration: The biomass is heated for several hours.

Under these conditions, the process favors the formation of the solid char, resulting in biochar yields of 25-35% by weight.

Fast Pyrolysis for Bio-Oil Production

In contrast, fast pyrolysis is used when the main goal is to produce liquid fuel. It is defined by much more aggressive conditions.

- Temperature: Much higher, ranging from 500°C to 700°C.

- Duration: Extremely short, with biomass heated very rapidly.

These conditions "crack" the biomass into vapors that, when cooled and condensed, form bio-oil. Biochar is still produced, but it is a secondary byproduct in a much smaller quantity.

Understanding the Trade-offs

Choosing a pyrolysis method involves balancing competing priorities. There is no single "best" approach; the optimal method depends entirely on your primary goal.

Yield vs. Throughput

Slow pyrolysis maximizes the percentage of feedstock converted into biochar. However, because it takes several hours per batch, the overall throughput (tons per day) of a given reactor is lower. Fast pyrolysis has a much higher throughput but yields far less biochar.

Equipment Complexity

Fast pyrolysis requires sophisticated engineering to achieve rapid heating rates and to quickly quench and collect the volatile vapors. Slow pyrolysis systems can often be simpler in design and operation.

Byproduct Management

You never produce just one output. A system designed for biochar must have a plan for utilizing or safely disposing of the bio-oil and syngas byproducts. Often, the syngas is looped back to provide the heat needed to sustain the pyrolysis reaction, improving energy efficiency.

Making the Right Choice for Your Goal

Your intended primary product dictates the correct pyrolysis parameters. To select the right path, first define your objective.

- If your primary focus is maximizing biochar yield for agricultural or carbon sequestration purposes: You must use slow pyrolysis, operating at lower temperatures (~400°C) for extended periods (hours).

- If your primary focus is producing liquid bio-oil as a renewable fuel source: You must use fast pyrolysis, operating at high temperatures (500-700°C) with very short residence times.

- If your primary focus is a balanced output or energy self-sufficiency: You can use intermediate conditions and design a system where the syngas and bio-oil byproducts are used to power the entire process.

By controlling temperature and time in an oxygen-free environment, you can precisely steer the decomposition of biomass to create the products you need.

Summary Table:

| Pyrolysis Method | Primary Goal | Temperature Range | Duration | Key Product Yield |

|---|---|---|---|---|

| Slow Pyrolysis | Maximize Biochar | ~400°C | Several Hours | 25-35% Biochar |

| Fast Pyrolysis | Maximize Bio-Oil | 500-700°C | Very Short (Seconds) | High Bio-Oil Yield |

Ready to design your optimal pyrolysis system? Whether your goal is maximizing biochar yield for carbon sequestration or producing bio-oil for renewable fuel, KINTEK has the expertise and laboratory equipment to support your R&D and scale-up. Our reactors and consumables are designed for precise thermal processing control. Contact our experts today to discuss how we can help you achieve your biomass conversion objectives.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

People Also Ask

- What are the limitations of pyrolysis? Key Economic and Technical Hurdles Explained

- How does heating rate affect pyrolysis? Control Product Yields for Biochar, Bio-Oil, or Syngas

- What is the difference between fast and slow biomass pyrolysis? Optimize Your Biofuel or Biochar Production

- How do you start a pyrolysis plant? A Step-by-Step Guide to Launching Your Waste-to-Energy Facility

- What is the yield of biochar in slow pyrolysis? Maximize Your Output Up to 30%

- How is gasification more advantageous than pyrolysis? Maximize Energy vs. Product Flexibility

- What is the best feedstock for biochar? Match Your Material to Your Goal for Maximum Impact

- What are the advantages and disadvantages of pyrolysis? Unlocking Value from Waste vs. Cost & Complexity