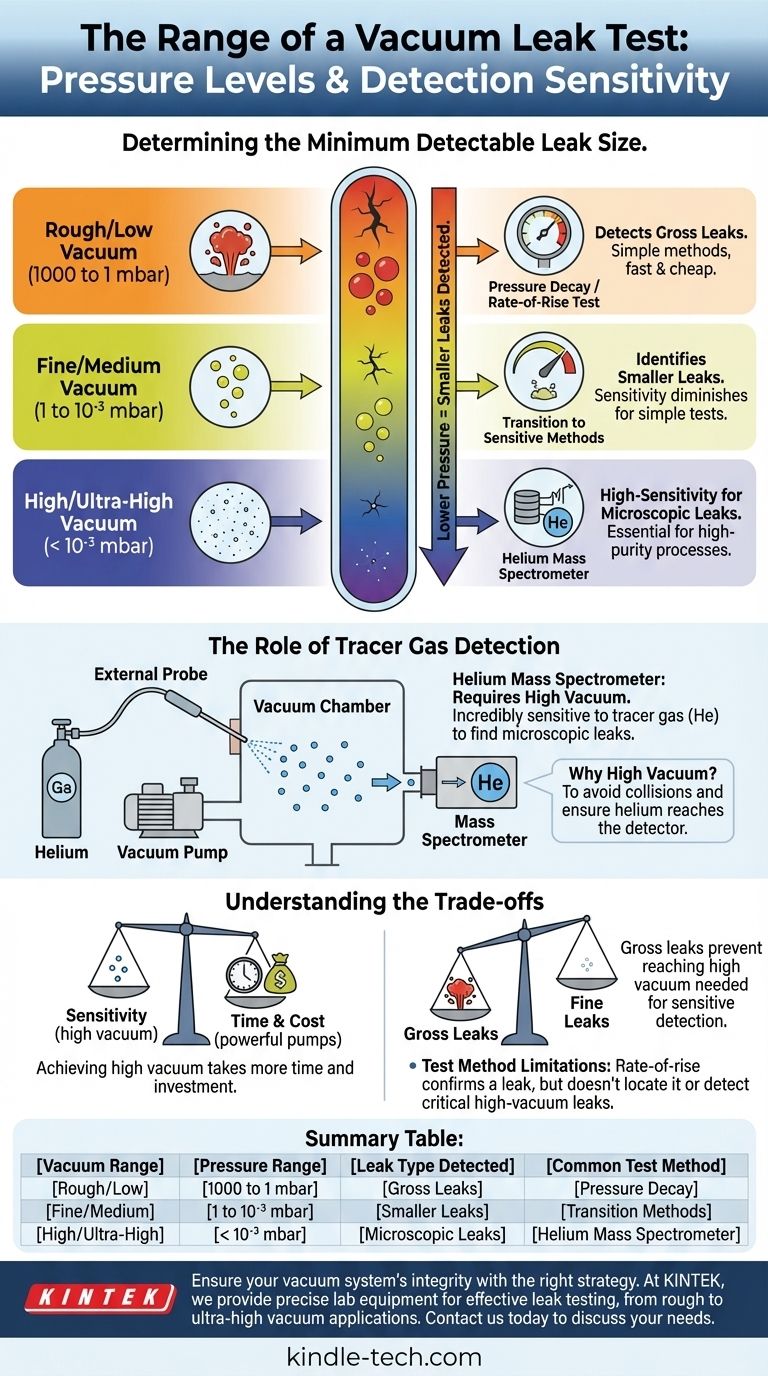

At its core, the "range" of a vacuum leak test refers to the vacuum level (pressure) at which the test is performed. This is not a single value, as tests can be conducted anywhere from a rough vacuum (near atmospheric pressure) down to an ultra-high vacuum. The specific pressure range you test within directly determines the minimum size of the leak you are able to detect.

The fundamental principle is that the deeper the vacuum you achieve, the smaller and more subtle the leak you can find. The choice of testing range is therefore a strategic decision based on the required integrity and operational pressure of the vacuum system.

How Vacuum Level Dictates Leak Detection

A vacuum system's integrity is only as good as the leaks you can find and fix. The vacuum level you can pull is the primary factor controlling the sensitivity of your leak detection method.

Rough/Low Vacuum Range (1000 to 1 mbar)

In this range, you are looking for gross leaks. These are large leaks that prevent the system from achieving a deep vacuum in the first place.

Methods used here are often simple, such as monitoring the rate of pressure rise (a "rate-of-rise" or "pressure decay" test) after isolating the vacuum pump.

Fine/Medium Vacuum Range (1 to 10⁻³ mbar)

As you move into a medium vacuum, you can begin to identify smaller leaks that might be missed in the rough vacuum range.

While rate-of-rise tests can still be used, their sensitivity diminishes. This range often serves as a transition point to more sophisticated methods.

High & Ultra-High Vacuum Range (< 10⁻³ mbar)

This is the domain for high-sensitivity leak detection. To find the microscopic leaks that affect high-purity processes or long-term vacuum stability, you must test at these low pressures.

The gold standard method here, as noted in testing procedures for vacuum furnaces, is using a helium mass spectrometer. This device requires a high vacuum to operate effectively, as it needs to distinguish a few tracer gas atoms from the background gas.

The Role of Tracer Gas Detection

Simply pulling a vacuum only tells you if there is a leak; it doesn't tell you where or how small it truly is. For that, you need a more advanced technique.

The Principle of Helium Leak Detection

This method involves evacuating the system to a high vacuum and then spraying a small amount of an inert tracer gas, typically helium, around suspected leak points on the outside.

If a leak exists, helium atoms are drawn into the vacuum system and travel to a detector, the mass spectrometer, which is specifically tuned to detect them.

Why High Vacuum is Necessary

A helium mass spectrometer is incredibly sensitive, but it cannot function in a high-pressure environment.

The system must be at a high vacuum (e.g., below 10⁻⁴ mbar) so that the few helium atoms entering through a leak can travel unimpeded to the detector without colliding with other gas molecules. This is why you must first fix large leaks before you can find small ones.

Understanding the Trade-offs

Choosing a leak detection range is not just about aiming for the highest vacuum possible. It involves balancing sensitivity with practicality.

Sensitivity vs. Time and Cost

Achieving a high or ultra-high vacuum takes significant time and requires powerful, expensive pump systems. A helium mass spectrometer is also a major investment. Testing for gross leaks at rough vacuum is comparatively fast and cheap.

Gross Leaks Can Mask Fine Leaks

A common pitfall is trying to find a fine leak when a gross leak is present. The large leak will prevent the system from ever reaching the high vacuum level required for the sensitive helium detector to work, rendering the test useless.

Test Method Limitations

A simple rate-of-rise test is useful for confirming a leak exists but provides no information on its location. It also lacks the sensitivity to detect leaks that are critical in high and ultra-high vacuum applications.

Making the Right Choice for Your Goal

The correct test range is determined entirely by your system's operational requirements and the consequences of a potential leak.

- If your primary focus is general processing or holding a rough vacuum: A pressure decay test performed in the rough to medium vacuum range is usually sufficient to find performance-inhibiting leaks.

- If your primary focus is high-purity manufacturing, scientific research, or long-term vacuum stability: You must test in the high or ultra-high vacuum range using a helium mass spectrometer to find the microscopic leaks that could compromise your work.

Ultimately, matching the test sensitivity to the application's demands ensures system reliability without unnecessary effort or expense.

Summary Table:

| Vacuum Range | Pressure Range | Leak Type Detected | Common Test Method |

|---|---|---|---|

| Rough/Low Vacuum | 1000 to 1 mbar | Gross Leaks | Pressure Decay / Rate-of-Rise |

| Fine/Medium Vacuum | 1 to 10⁻³ mbar | Smaller Leaks | Transition to Sensitive Methods |

| High/Ultra-High Vacuum | < 10⁻³ mbar | Microscopic Leaks | Helium Mass Spectrometer |

Ensure your vacuum system's integrity with the right leak detection strategy.

At KINTEK, we specialize in providing the precise lab equipment and consumables needed for effective vacuum leak testing—from robust rough vacuum setups to high-sensitivity helium mass spectrometers for ultra-high vacuum applications. Our experts can help you select the right tools to match your system's operational demands, balancing sensitivity, time, and cost.

Contact us today via our contact form to discuss your specific vacuum system requirements and discover how KINTEK can enhance your lab's reliability and performance.

Visual Guide

Related Products

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- KF/ISO/CF Ultra-High Vacuum Stainless Steel Flange Pipe/Straight Pipe/Tee/Cross

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

People Also Ask

- How does a high-temperature vacuum sintering furnace contribute to the formation of Fe-Cr-Al porous materials?

- How does a vacuum oven contribute to the quality of NIPU films? Achieve Superior Material Density and Strength

- Is annealing a slow process? The Critical Role of Controlled Cooling in Heat Treatment

- Why is a high vacuum system necessary when measuring the hydrogen solubility of aluminum? Ensure Data Purity

- Why is nitrogen used in sintering? Balancing Cost, Oxidation Control, and Material Properties

- How does a vacuum diffusion bonding furnace contribute to titanium laminates? Precision for Near-Alpha Alloys

- What is the normal temperature for sintering? Master the 750°C to 1300°C Range for Optimal Results

- What is the primary function of a small vertical vacuum furnace in magnesium refining? Maximize Purity & Recovery