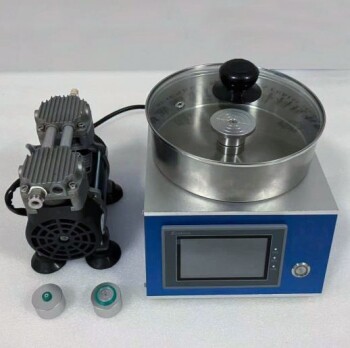

A vacuum pump is indispensable in freeze drying, enabling the sublimation process by creating and maintaining the necessary low-pressure environment. It ensures efficient moisture removal while preserving the structural integrity of sensitive materials like pharmaceuticals or food. The pump's performance directly impacts drying speed, product quality, and energy efficiency.

Key Points Explained:

-

Pressure Reduction for Sublimation

- The lab vacuum pump lowers chamber pressure to ~0.1-0.001 mbar, creating conditions where ice transitions directly to vapor (sublimation) at temperatures as low as -40°C

- Without this pressure drop, materials would melt rather than dry, compromising product structure and stability

-

Two-Phase Drying Support

- Primary Drying: Removes ~95% of free water by maintaining constant vacuum during ice sublimation

- Secondary Drying: Eliminates bound water molecules by sustaining vacuum while gradually raising temperature

-

Process Efficiency Factors

- Pumping speed determines how quickly optimal vacuum levels are achieved

- Ultimate vacuum pressure affects the final moisture content - deeper vacuums yield drier products

- Oil-free pumps prevent contamination in sensitive applications like vaccine production

-

System Integration

- Works with condensers to trap vaporized water, preventing pump overload

- Modern systems use vacuum sensors to automatically adjust pump operation for energy savings

-

Material Preservation

- Low-temperature drying protects:

- Protein structures in biologics

- Flavor compounds in food

- Reactivity in chemicals

- Prevents oxidation by removing air from the chamber

- Low-temperature drying protects:

Have you considered how pump selection varies between pharmaceutical freeze dryers (requiring ultra-clean operation) versus industrial food processing (prioritizing high throughput)? The right vacuum system balances these technical demands with operational costs, becoming the unseen workhorse behind stable medications and crispy instant coffee alike.

Summary Table:

| Role of Vacuum Pump | Key Benefits |

|---|---|

| Pressure Reduction | Enables sublimation at low temperatures (-40°C), preventing material melting |

| Two-Phase Drying Support | Removes 95% free water (primary drying) and bound moisture (secondary drying) |

| Process Efficiency | Faster drying speeds, lower final moisture content, and energy savings |

| Material Preservation | Protects proteins, flavors, and chemicals while preventing oxidation |

| System Integration | Works with condensers and sensors for automated, contamination-free operation |

Optimize your freeze-drying process with the right vacuum pump! At KINTEK, we specialize in high-performance lab equipment tailored to your needs—whether for pharmaceuticals, food processing, or chemical applications. Contact us today to discuss how our vacuum solutions can enhance your freeze-drying efficiency and product quality.