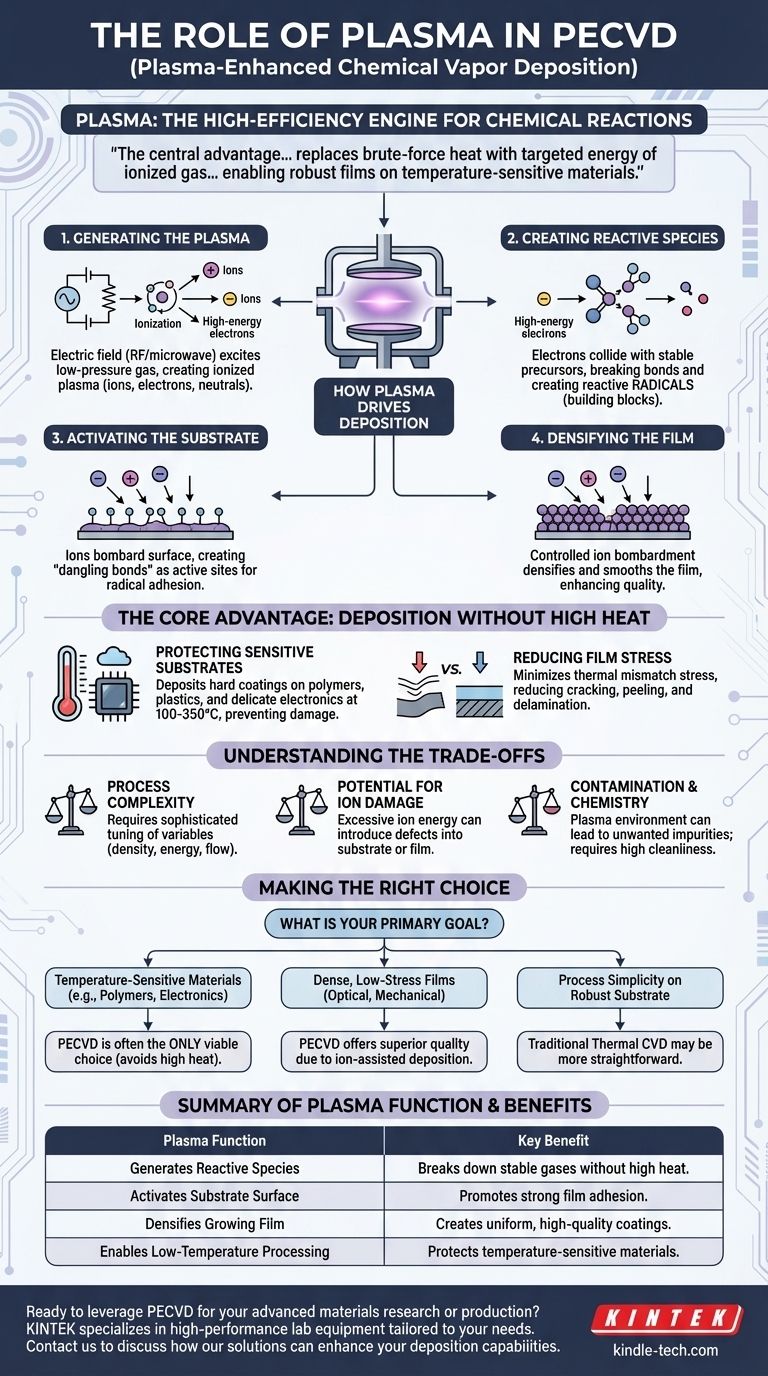

In Plasma-Enhanced Chemical Vapor Deposition (PECVD), plasma's primary role is to provide the energy required to break down stable precursor gases into reactive chemical species. This allows for the deposition of high-quality thin films at significantly lower temperatures than are possible with purely thermal methods, making it an indispensable process for modern materials science and manufacturing.

The central advantage of using plasma is that it replaces the brute-force energy of high heat with the targeted energy of ionized gas. This fundamental shift enables the creation of robust, strongly-bonded films on materials that could never withstand the temperatures of traditional deposition processes.

How Plasma Drives the Deposition Process

To understand PECVD, you must first understand how plasma acts as a highly efficient engine for chemical reactions. It isn't just a heat source; it's a complex environment that actively prepares both the gases and the target surface for deposition.

Generating the Plasma

Plasma is often called the fourth state of matter. It is a partially ionized gas containing a mix of neutral atoms, positively charged ions, and high-energy free electrons.

In PECVD systems, this state is created not by extreme heat, but by applying a strong electric field—typically from a radio frequency (RF) or microwave source—to a low-pressure gas. This electrical energy excites the gas, stripping electrons from atoms and creating the energetic plasma environment.

Creating Reactive Species

The free electrons within the plasma are the true workhorses of the process. Accelerated by the electric field, these high-energy electrons collide with the stable precursor gas molecules introduced into the chamber.

These collisions have enough energy to break strong chemical bonds, creating highly reactive molecular fragments called radicals. These radicals are the essential building blocks for the thin film and are far more likely to react and bond to a surface than their stable parent molecules.

Activating the Substrate Surface

Simultaneously, the heavier ions in the plasma are drawn toward the substrate. This ion bombardment is a critical secondary effect.

When ions strike the surface, they transfer energy, creating "dangling bonds"—unoccupied bonding sites that are chemically active. These activated sites act as perfect anchors for the incoming radicals, promoting strong adhesion and the initial growth of the film.

Densifying the Growing Film

This controlled ion bombardment continues as the film grows. It helps to physically compact the depositing material and can even etch away weakly bonded atoms or undesirable byproducts. The result is a denser, more uniform, and higher-quality film than could be achieved without this effect.

The Core Advantage: Deposition Without High Heat

The ability to create reactive species without high temperatures is the defining feature of PECVD and the reason for its widespread use.

Protecting Sensitive Substrates

Many advanced applications require depositing films onto materials that are temperature-sensitive. This includes polymers, plastics, and fully-fabricated semiconductor devices with delicate integrated circuits.

PECVD allows for the deposition of hard, protective coatings like silicon nitride or silicon dioxide at temperatures as low as 100-350°C, a range that prevents damage or degradation to the underlying substrate.

Reducing Inherent Film Stress

High-temperature processes involve significant expansion and contraction as the substrate and film cool down. This mismatch creates enormous mechanical stress, which can cause the film to crack, peel, or delaminate.

By operating at lower temperatures, PECVD minimizes this thermal stress, leading to more mechanically stable and reliable films.

Understanding the Trade-offs

While powerful, PECVD is not a universal solution. An objective assessment requires understanding its inherent complexities.

Process Complexity

A PECVD system involves more variables than a simple thermal process. Controlling plasma density, ion energy, gas flow, and electrical power requires sophisticated equipment and precise process tuning to achieve repeatable results.

Potential for Ion Damage

The same ion bombardment that densifies the film can also cause damage if not properly controlled. Excessively high ion energy can introduce defects into the substrate or the growing film, which is a critical concern in sensitive electronic applications.

Contamination and Chemistry

The plasma environment is chemically complex. Unwanted reactions can sometimes occur, potentially introducing impurities into the film. The chamber itself must also be kept impeccably clean to avoid contaminating the process.

Making the Right Choice for Your Goal

Understanding the role of plasma allows you to determine if PECVD is the appropriate tool for your specific engineering challenge.

- If your primary focus is depositing on temperature-sensitive materials (like polymers or electronics): PECVD is often the only viable choice, as it avoids the destructive high heat of other methods.

- If your primary focus is creating dense, low-stress films for optical or mechanical applications: The ion-assisted deposition in PECVD produces superior film quality and adhesion compared to many low-temperature alternatives.

- If your primary focus is process simplicity on a thermally robust substrate: A traditional thermal CVD process may be a more straightforward and cost-effective solution, assuming the high temperatures are acceptable.

Ultimately, leveraging plasma in deposition is about using controlled energy to achieve material properties that would otherwise be impossible.

Summary Table:

| Plasma Function | Key Benefit |

|---|---|

| Generates Reactive Species | Breaks down stable gases without high heat |

| Activates Substrate Surface | Promotes strong film adhesion |

| Densifies Growing Film | Creates uniform, high-quality coatings |

| Enables Low-Temperature Processing | Protects temperature-sensitive materials |

Ready to leverage PECVD for your advanced materials research or production? KINTEK specializes in providing high-performance lab equipment and consumables tailored to your laboratory's unique needs. Our expertise in plasma-enhanced processes can help you achieve superior thin film results on even the most sensitive substrates. Contact us today to discuss how our solutions can enhance your deposition capabilities and drive your innovations forward.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory CVD Boron Doped Diamond Materials

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition