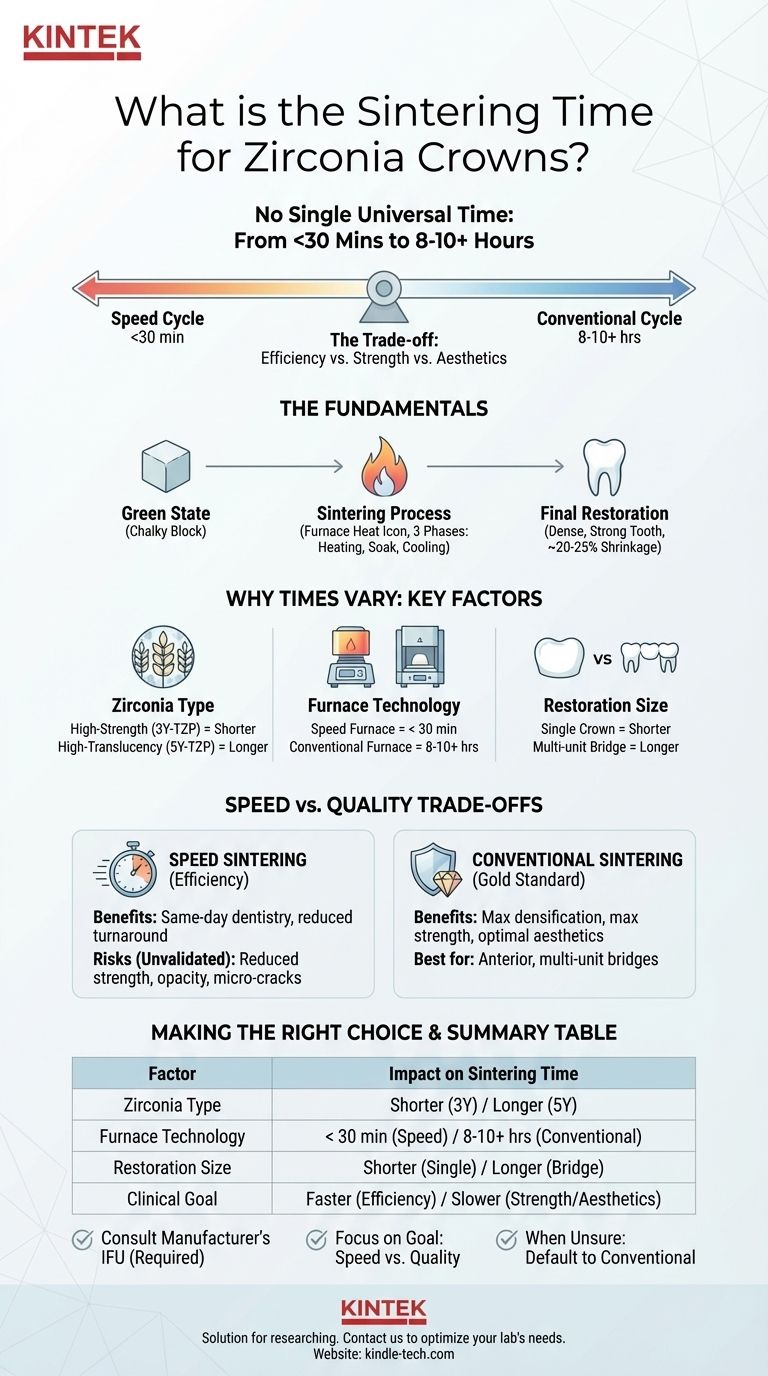

The short answer is there is no single, universal sintering time for all zirconia crowns. The duration is dictated entirely by the specific brand and type of zirconia, the furnace used, and the desired properties of the final restoration. Sintering cycles can range from a "speed" cycle of under 30 minutes to a conventional cycle lasting over 8-10 hours.

The core principle to understand is that sintering time represents a critical trade-off between clinical efficiency, mechanical strength, and final aesthetics. Choosing the correct cycle is not about finding one number, but about aligning the manufacturer's protocol with your specific clinical goal.

The Fundamentals of Zirconia Sintering

Sintering is the critical heat treatment process that transforms a chalky, oversized zirconia milling block (the "green state") into a dense, strong, final dental restoration. This process is essential for achieving the material's intended clinical properties.

The Purpose of Sintering

The primary goal of sintering is to reduce porosity and dramatically increase the density of the ceramic. This is accomplished by heating the material to a specific high temperature, holding it there, and then carefully cooling it.

The Shrinkage Factor

During this process, zirconia undergoes a predictable and significant amount of shrinkage, often around 20-25%. CAD/CAM software accounts for this shrinkage by designing an oversized restoration that, after sintering, shrinks to the precise intended dimensions.

The Three Phases of a Sintering Cycle

A complete sintering program consists of three distinct phases:

- Heating: A controlled ramp-up in temperature to avoid thermal shock.

- Sintering: A "soak" or "hold" at the peak temperature (e.g., 1450°C - 1550°C) where densification occurs.

- Cooling: A controlled ramp-down to room temperature to prevent fractures.

Why Sintering Times Vary: Key Factors

The wide range in sintering times is not arbitrary. It is a function of material science, equipment capabilities, and the physical demands of the restoration.

Zirconia Generation and Translucency

Different generations of zirconia have different chemical compositions and grain structures. High-strength, opaque zirconias (like 3Y-TZP) can often tolerate faster cycles. In contrast, highly translucent, aesthetic zirconias (like 5Y-TZP) are more sensitive to the sintering protocol and typically require longer, slower cycles to achieve their optimal optical properties without compromising strength.

Furnace Technology

The type of sintering furnace is a major determinant. Modern "speed" furnaces use microwave or advanced induction technology to heat and cool materials much faster than traditional resistance-heating ovens. However, you can only use a speed cycle if both the furnace and the specific zirconia material have been validated for that process.

Restoration Size and Span

Heat must penetrate the entire restoration evenly, from the surface to the core. A small, single-unit crown can be heated and cooled much more rapidly than a large, multi-unit bridge. Rushing the process on a large-span bridge risks uneven sintering, leading to internal stresses and a higher potential for premature failure.

Understanding the Trade-offs: Speed vs. Quality

The decision to use a fast or slow sintering cycle is a clinical and business decision with clear consequences.

The Allure of Speed Sintering

The primary benefit of speed sintering is efficiency. It enables same-day dentistry and dramatically reduces the turnaround time for lab-fabricated crowns. For a single posterior crown, a validated speed cycle can deliver a clinically acceptable restoration in a fraction of the time.

The Risks of Rushing the Process

Using an unvalidated speed cycle, or rushing a material not designed for it, can be detrimental. Potential risks include reduced flexural strength, compromised translucency (making the crown appear more opaque and less vital), and the introduction of micro-cracks from thermal shock. These issues can lead to an unaesthetic result or, worse, a catastrophic restoration failure.

Conventional Sintering: The Gold Standard

For decades, long, slow sintering cycles have been the gold standard for a reason. This method ensures the most complete densification, maximizes flexural strength, and brings out the best possible aesthetic qualities of the material. For anterior cases or multi-unit bridges, a conventional cycle is almost always the safest and most predictable choice.

Making the Right Choice for Your Goal

Always begin by consulting the manufacturer's instructions for use (IFU) for your specific zirconia. The validated cycle times provided are not suggestions; they are requirements for achieving the stated properties.

- If your primary focus is maximum strength and aesthetics (e.g., a long-span bridge): Use the manufacturer's recommended conventional, long sintering cycle.

- If your primary focus is rapid, same-day turnaround for a single posterior unit: Use a zirconia and furnace combination specifically validated and approved for speed sintering.

- If you are ever unsure or working with a new material: Default to the standard, conventional sintering cycle to ensure the highest quality and safety.

Ultimately, mastering the sintering process is about precisely following validated protocols to deliver a safe, strong, and beautiful restoration.

Summary Table:

| Factor | Impact on Sintering Time |

|---|---|

| Zirconia Type | High-strength (3Y-TZP) = Shorter cycle; High-translucency (5Y-TZP) = Longer cycle |

| Furnace Technology | Speed Furnace = < 30 min; Conventional Furnace = 8-10+ hours |

| Restoration Size | Single Crown = Shorter cycle; Multi-unit Bridge = Longer cycle |

| Clinical Goal | Speed/Strength Trade-off: Faster cycles for efficiency, slower cycles for maximum strength/aesthetics |

Achieve perfect sintering results every time. The right lab equipment is critical for predictable, high-quality zirconia restorations. KINTEK specializes in precision dental furnaces and consumables designed for dental laboratories. Whether you need a speed furnace for same-day dentistry or a conventional furnace for maximum strength and aesthetics, our experts can help you select the ideal equipment for your workflow and materials.

Contact us today to discuss your lab's needs and ensure your sintering process is optimized for success. Get in touch via our contact form.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What properties of dental zirconia parts are affected by the sintering temperature? Master Thermal Precision

- What is the firing temperature of dental ceramics? A Guide to Precise Thermal Processing

- How are Dental Press Furnaces used with modern dental technologies? Optimize Your CAD/CAM Digital Workflow

- What temperature is a dental sintering furnace? Mastering the Material-Specific Thermal Cycle