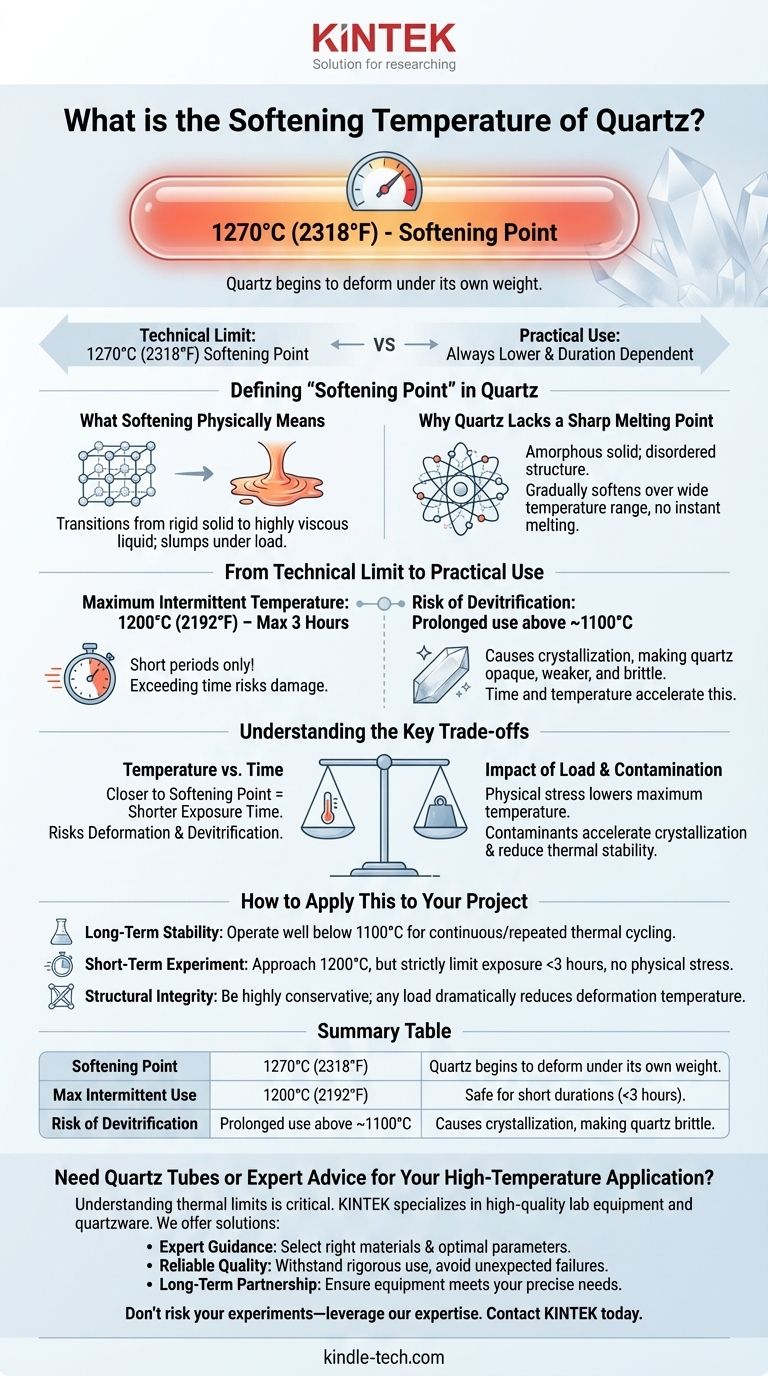

In technical terms, the softening point of a quartz tube is approximately 1270°C (2318°F). This is the specific temperature at which the material begins to lose its rigidity and deform under its own weight.

The key distinction for any high-temperature application is the difference between the material's absolute softening point and its safe, practical working temperature, which is always lower and depends heavily on the duration of use.

Defining "Softening Point" in Quartz

Understanding what happens to quartz at extreme temperatures is crucial for using it safely and effectively. Unlike metals, quartz glass doesn't have a sharp, defined melting point.

What Softening Physically Means

The softening point is a standardized measure corresponding to a specific viscosity. At this temperature, quartz transitions from a rigid solid to a highly viscous liquid, causing it to slump or deform, especially under any physical load.

Why Quartz Lacks a Sharp Melting Point

Quartz is an amorphous solid, meaning its atomic structure is disordered, much like a liquid. Instead of melting instantly at a specific temperature, it gradually softens over a wide temperature range as it heats up.

From Technical Limit to Practical Use

The softening point is a material property, but the maximum operating temperature is a practical engineering limit. For quartz, this limit is significantly lower than its softening point.

Maximum Intermittent Temperature

You can push quartz to higher temperatures for short periods. A common guideline is a maximum temperature of 1200°C (2192°F), but usage should not exceed 3 hours at this level to prevent damage.

The Risk of Devitrification

Holding quartz at high temperatures, even below its softening point, can cause a process called devitrification. The amorphous structure begins to crystallize, turning the quartz opaque and making it mechanically weaker and more brittle upon cooling. Time and temperature accelerate this process.

Understanding the Key Trade-offs

Using quartz near its thermal limits requires balancing performance against material longevity and safety.

Temperature vs. Time

The most critical trade-off is time. The closer you operate to the softening point, the shorter the acceptable exposure time becomes. Pushing past recommended durations risks not just deformation but also devitrification, which permanently compromises the material.

Impact of Load and Contamination

Any physical stress or load on the quartz will lower its effective maximum temperature, causing it to deform at temperatures well below the official softening point. Similarly, surface contaminants can act as fluxes, accelerating crystallization and reducing the material's thermal stability.

How to Apply This to Your Project

Choosing the correct operating parameters is essential for successful and repeatable outcomes.

- If your primary focus is long-term stability: Operate quartz components well below 1100°C for any continuous or repeated thermal cycling.

- If your primary focus is a short-term experiment: You can approach 1200°C, but strictly limit the exposure time to under three hours and ensure the material is not under physical stress.

- If your primary focus is structural integrity: Be highly conservative with your temperature limits, as any load dramatically reduces the temperature at which deformation begins.

Ultimately, respecting the thermal properties of quartz is the key to leveraging its remarkable capabilities safely.

Summary Table:

| Property | Temperature | Key Consideration |

|---|---|---|

| Softening Point | 1270°C (2318°F) | Quartz begins to deform under its own weight. |

| Max Intermittent Use | 1200°C (2192°F) | Safe for short durations (<3 hours). |

| Risk of Devitrification | Prolonged use above ~1100°C | Causes crystallization, making quartz brittle. |

Need Quartz Tubes or Expert Advice for Your High-Temperature Application?

Understanding the precise thermal limits of quartz is critical for the safety and success of your laboratory processes. At KINTEK, we specialize in high-quality lab equipment and consumables, including quartzware designed for demanding applications.

We provide more than just products; we offer solutions:

- Expert Guidance: Our team can help you select the right quartz materials and determine the optimal operating parameters for your specific experiments, balancing performance with material longevity.

- Reliable Quality: Our quartz products are manufactured to withstand rigorous use, helping you avoid unexpected failures due to thermal stress or devitrification.

- Long-Term Partnership: We work with you to ensure your lab equipment meets your precise needs, from initial selection to ongoing support.

Don't risk your experiments or equipment—leverage our expertise.

Contact KINTEK today to discuss your high-temperature requirements and ensure you get the right solution for your laboratory.

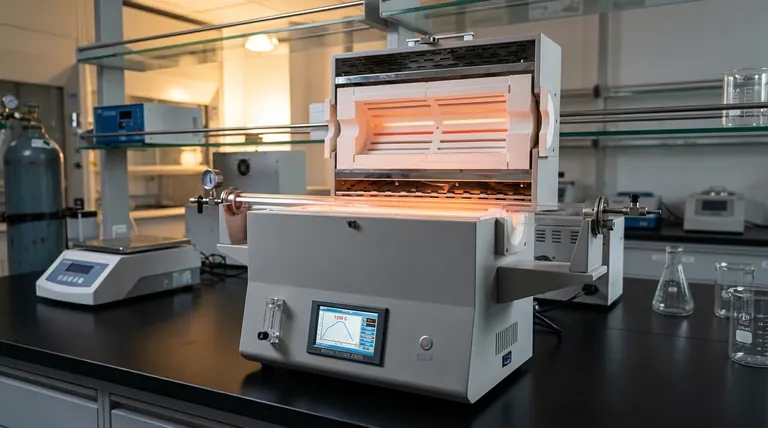

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

People Also Ask

- What is the difference between sputtering and electron beam? Choosing the Right Thin Film Deposition Method

- Can carbon be sputtered? Unlock the Power of Diamond-Like Carbon (DLC) Films

- What is the use of furnace in a laboratory? Essential Tool for Material Transformation

- What is the difference between evaporation and sputtering in coating technology? Choose the Right Method for Your Lab

- What is the difference between short path and thin film? Choosing the Right Distillation Method for Your Lab

- Can graphite withstand high-temperature? Maximizing Performance in Controlled Atmospheres

- What are the applications of electron beam? A Guide to Precision Energy Delivery

- What is HIP hot isostatic pressing used for? Achieve Maximum Density & Reliability