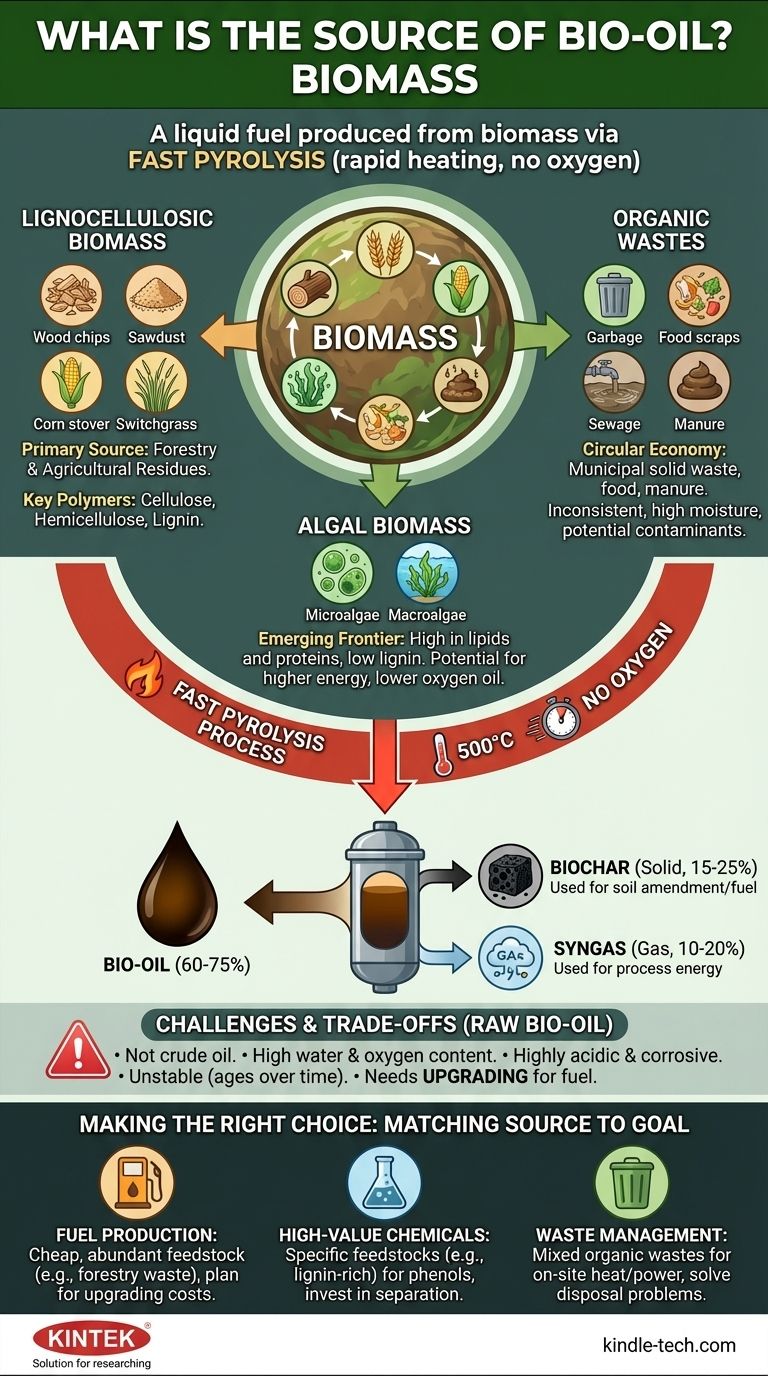

In short, bio-oil is a liquid fuel produced from biomass. It is the result of a process called fast pyrolysis, which involves rapidly heating organic materials like wood, agricultural waste, or even algae to around 500°C in the complete absence of oxygen. This thermal process vaporizes the solid biomass, and when these vapors are rapidly cooled and condensed, they form a dark, dense liquid known as bio-oil or pyrolysis oil.

The source of bio-oil is not a single material, but a vast category of organic matter called biomass. This means the specific properties and potential value of any given bio-oil are directly determined by the feedstock from which it was derived—wood waste will produce a very different oil than manure or algae.

What is "Biomass"? The Feedstock for Bio-Oil

Bio-oil is fundamentally a transformed version of the carbon stored in organic matter. The type and quality of this starting material, or feedstock, is the single most important factor influencing the final product.

Lignocellulosic Biomass: The Primary Source

Most bio-oil today is derived from lignocellulosic biomass. This is a technical term for the dry, structural matter of plants.

Common sources include forestry residues (wood chips, sawdust), agricultural residues (corn stover, wheat straw), and dedicated energy crops (switchgrass, miscanthus). This biomass is primarily composed of three polymers: cellulose, hemicellulose, and lignin, each of which breaks down into different families of chemical compounds in the final bio-oil.

Algal Biomass: An Emerging Frontier

Algae represents another promising category of feedstock. Unlike woody biomass, algae can be high in lipids (fats) and proteins and generally has very low lignin content.

Pyrolysis of algae can produce a bio-oil with a higher energy content and lower oxygen content, making it potentially easier to upgrade into conventional fuels. However, cultivating and harvesting algae at scale remains a significant challenge.

Organic Wastes: A Circular Economy Approach

A wide range of organic wastes can also be converted into bio-oil, including municipal solid waste, food scraps, sewage sludge, and animal manures.

Using waste as a feedstock is a powerful application of circular economy principles. However, these sources are often inconsistent, high in moisture, and may contain contaminants, which complicates the pyrolysis process and affects the quality of the resulting bio-oil.

The Production Process: From Solid to Liquid

Bio-oil does not exist in nature. It is an engineered product created through a specific thermochemical conversion process.

The Core Technology: Fast Pyrolysis

The key to producing bio-oil is fast pyrolysis. The "fast" is critical: the biomass must be heated to the target temperature in a matter of seconds.

Think of it as flash-vaporizing the biomass rather than slowly burning it. This extreme speed maximizes the breakdown of the solid structure into condensable vapors, which become the liquid bio-oil, instead of allowing it to turn into solid char.

Products of Pyrolysis: Not Just Oil

Fast pyrolysis doesn't just produce one thing. The process fractionates the biomass into three distinct products:

- Bio-oil (Liquid): Typically 60-75% of the product by weight. This is the primary target.

- Biochar (Solid): A stable, carbon-rich solid similar to charcoal, making up 15-25% of the yield. It can be used as a soil amendment or solid fuel.

- Syngas (Gas): Non-condensable gases like carbon monoxide and hydrogen, making up 10-20% of the yield. This gas is often recycled to provide the energy needed to run the pyrolysis process itself.

Understanding the Trade-offs: The Challenges of Bio-Oil

While often called an "oil," raw bio-oil cannot be used directly in a standard engine or refinery. It is a complex, challenging intermediate product.

It's Not Crude Oil: Key Differences

Bio-oil is fundamentally different from fossil crude oil. It has a high water content (15-30%) and high oxygen content, which lowers its energy density.

Furthermore, it is highly acidic and corrosive to standard pipes and storage tanks. It is also unstable, meaning its viscosity and chemical makeup can change over time, a process known as aging.

The Need for Upgrading

Because of these properties, bio-oil must be "upgraded" before it can be used as a transportation fuel. Upgrading is a form of refining that typically involves catalytic processes (like hydrotreating) to remove oxygen, reduce acidity, and increase stability.

This upgrading step adds significant cost and complexity to the overall fuel production pathway, which is a major barrier to its widespread commercial adoption as a simple fuel replacement.

From Waste Stream to Value Stream

The most promising application of bio-oil may not be as a bulk fuel, but as a source of valuable chemicals. This is the core of the "biorefinery" concept.

The complex mixture contains hundreds of organic compounds, including phenols, furans, and anhydrosugars, derived from the breakdown of lignin and cellulose. As your reference notes, separating these valuable substituted phenols and aromatics could be far more profitable than simply burning the oil for energy. This approach turns a low-grade fuel into a high-value chemical feedstock.

Making the Right Choice for Your Goal

The value of bio-oil is entirely dependent on the goal of the project. The source material must be matched to the desired outcome.

- If your primary focus is large-scale fuel production: Prioritize cheap, abundant, and consistent feedstocks like forestry waste, and plan for the significant cost and technical challenges of the upgrading process.

- If your primary focus is creating high-value chemicals: Select specific feedstocks known to produce high yields of target molecules (e.g., lignin-rich biomass for phenols) and invest in advanced separation technologies.

- If your primary focus is waste management: Use mixed organic wastes to generate bio-oil for on-site heat and power, creating value from a disposal problem without needing to meet stringent fuel or chemical-grade standards.

Ultimately, understanding that bio-oil's source dictates its final composition is the key to unlocking its potential as a next-generation renewable resource.

Summary Table:

| Biomass Feedstock Category | Common Examples | Key Characteristics |

|---|---|---|

| Lignocellulosic Biomass | Wood chips, agricultural residues (e.g., corn stover) | Primary source; high in cellulose, hemicellulose, and lignin. |

| Algal Biomass | Microalgae, macroalgae | High lipid content; potential for higher energy bio-oil. |

| Organic Wastes | Municipal solid waste, food scraps, manure | Circular economy approach; often inconsistent and high in moisture. |

Ready to explore how bio-oil production can fit into your laboratory's research or sustainability goals? KINTEK specializes in providing the high-quality lab equipment and consumables needed for pyrolysis research and biomass analysis. Whether you are developing new feedstocks, optimizing conversion processes, or analyzing bio-oil composition, our solutions support your innovation. Contact our experts today to discuss how we can help you advance your renewable energy projects.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the factors that affect heat transfer? Master the Key Variables for Optimal Thermal Performance

- Where is XRF used? A Guide to Non-Destructive Elemental Analysis Applications

- What is the purpose of using permeable steel mesh containers for the synthesis of non-extruded ferroalloy samples?

- What is a drying oven? A Guide to Controlled Moisture Removal and Thermal Processing

- How does laboratory drying equipment affect the performance of hydrogel carriers? Optimize Drug Loading and Release

- What is the difference between a furnace and an oven in a laboratory? Choose the Right Tool for Your Lab's Heat Needs

- How does high-power ultrasonic dispersion equipment contribute to graphene exfoliation? Achieve Superior Material Purity

- What is the meaning of physical vapor deposition? A Guide to High-Performance Thin Film Coating