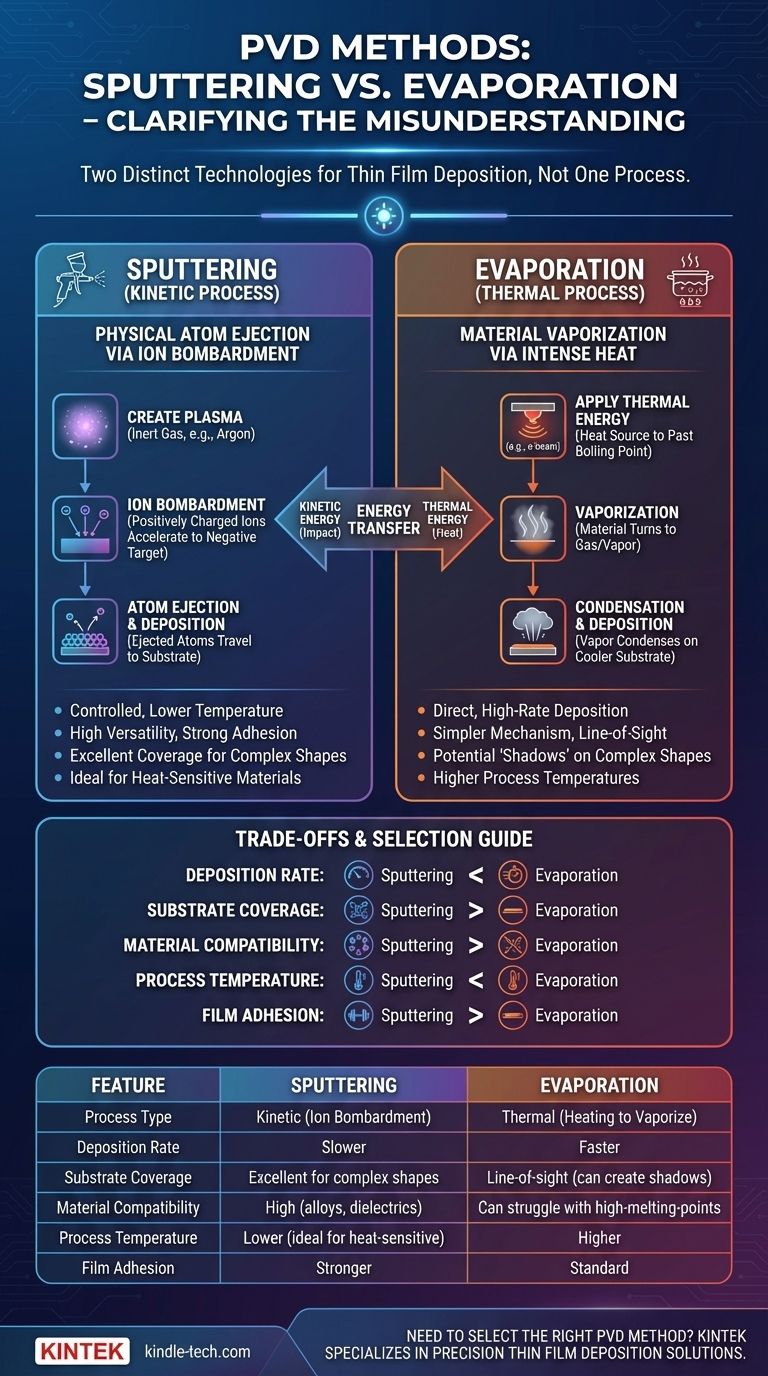

To be precise, the phrase "sputtering process of evaporation" describes a misunderstanding of two distinct technologies. Sputtering is not a form of evaporation. Sputtering is a kinetic process that uses ion bombardment to physically knock atoms off a target, while evaporation is a thermal process that uses heat to turn a material into a vapor. Both are methods of Physical Vapor Deposition (PVD) used to create thin films, but they operate on entirely different principles.

The core distinction is one of energy transfer. Sputtering uses kinetic energy—like a microscopic sandblaster—to eject atoms from a source. Evaporation uses thermal energy—heating a material until it boils—to create a vapor that condenses on a substrate.

The Mechanics of Sputtering

Sputtering is a highly controlled, lower-temperature deposition method prized for its versatility and the quality of the films it produces. The process unfolds in a vacuum chamber filled with an inert gas.

Creating the Plasma

First, a low-pressure inert gas, typically Argon, is introduced into the vacuum chamber. A strong electric field is applied, which energizes the gas and strips electrons from the Argon atoms, creating a plasma—a glowing, ionized gas.

Ion Bombardment

The source material, known as the target, is given a negative electrical charge. This causes the positively charged Argon ions from the plasma to accelerate and violently collide with the target surface.

Atom Ejection and Deposition

Each collision has enough kinetic energy to knock atoms or molecules loose from the target material. These ejected atoms travel through the chamber and deposit onto the substrate, gradually building up a thin, uniform film.

How Evaporation Fundamentally Differs

Evaporation is a more direct, high-rate deposition method. Its mechanism is simpler but comes with a different set of constraints.

The Role of Thermal Energy

Instead of using kinetic collisions, evaporation uses intense heat to raise the source material's temperature past its boiling point. The material transitions into a gaseous phase, or vapor, inside the vacuum chamber. A common method for this is electron beam (e-beam) evaporation, which uses a focused beam of electrons to heat the source material.

Deposition by Condensation

This vapor travels through the vacuum and condenses on the cooler substrate, forming a solid thin film. Because the vapor travels in a straight line from the source, this is considered a "line-of-sight" process.

Understanding the Trade-offs

Choosing between sputtering and evaporation depends entirely on the specific requirements of the final product. Neither is universally superior; they are tools designed for different tasks.

Deposition Rate

Evaporation is generally much faster than sputtering. The high thermal energy creates a large volume of vapor quickly, leading to rapid film growth. Sputtering is a more deliberate, atom-by-atom process and is therefore slower.

Substrate Coverage

Sputtering provides far better coating coverage on complex, non-flat substrates. The sputtered atoms are ejected in many directions and scatter within the plasma, allowing them to coat sidewalls and intricate features more evenly. Evaporation's "line-of-sight" nature can create "shadows" behind features.

Material Compatibility and Adhesion

Sputtering is highly versatile and can deposit a vast range of materials, including alloys and dielectrics, with their composition intact. Because the sputtered atoms arrive with higher energy, they often form denser films with stronger adhesion to the substrate. Evaporation can struggle with materials that have very high melting points or whose components evaporate at different rates.

Process Temperature

Sputtering is a lower-temperature process. The substrate does not need to be heated significantly, making sputtering ideal for coating heat-sensitive materials like plastics. Evaporation involves intense heat at the source, which can radiate and damage delicate substrates.

Making the Right Choice for Your Goal

Your application's specific needs will dictate the correct PVD method.

- If your primary focus is speed and high throughput for simple geometries: Evaporation is the more efficient and economical choice.

- If your primary focus is coating complex shapes with a uniform film: Sputtering offers superior conformity and step coverage.

- If your primary focus is depositing alloys, compounds, or dielectrics: Sputtering provides better control over the final film's composition and purity.

- If your primary focus is coating heat-sensitive substrates: Sputtering's lower-temperature operation is a critical advantage.

Understanding the fundamental difference between kinetic ejection and thermal vaporization is the key to selecting the right tool for your engineering challenge.

Summary Table:

| Feature | Sputtering | Evaporation |

|---|---|---|

| Process Type | Kinetic (ion bombardment) | Thermal (heating to vaporize) |

| Deposition Rate | Slower | Faster |

| Substrate Coverage | Excellent for complex shapes | Line-of-sight (can create shadows) |

| Material Compatibility | High (alloys, dielectrics) | Can struggle with high-melting-point materials |

| Process Temperature | Lower (ideal for heat-sensitive substrates) | Higher |

| Film Adhesion | Stronger | Standard |

Need to select the right PVD method for your application? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision thin film deposition solutions. Our experts can help you choose between sputtering and evaporation systems to achieve optimal film quality, uniformity, and adhesion for your specific substrates and materials. Contact us today to discuss your project requirements and enhance your lab's capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- Can you test diamonds with a machine? A Guide to Picking the Right Tool

- How can you control temperature inside a resistance furnace? Master Precise Thermal Management

- Why is KBr and NaCl used in IR spectroscopy? Achieve Clear, Accurate Sample Analysis

- What are the ceramic materials applicable to sintering? A Guide to Choosing the Right Material

- Why is laboratory stirring equipment essential in the Sol-Gel process? Achieving Chemical Homogeneity and Stability

- What products are manufactured with titanium? The Ultimate Guide to High-Performance Materials

- What is the annealing process in industry? A Guide to Relieving Stress and Restoring Ductility

- Why must PEO and lithium salt raw materials be pre-treated in a vacuum drying oven? Ensure Battery Stability