At its core, the study of biomass pyrolysis is the science of thermally decomposing organic material, like wood or agricultural waste, at high temperatures in an environment without oxygen. Instead of burning the material, this process chemically converts it into more stable and energy-dense products, primarily a solid carbon-rich material called biochar, as well as a liquid (bio-oil) and a gas (syngas).

The fundamental goal of pyrolysis is not to destroy biomass, but to transform and upgrade it. By removing water and less stable compounds, the process preserves and concentrates the carbon into more valuable and useful forms.

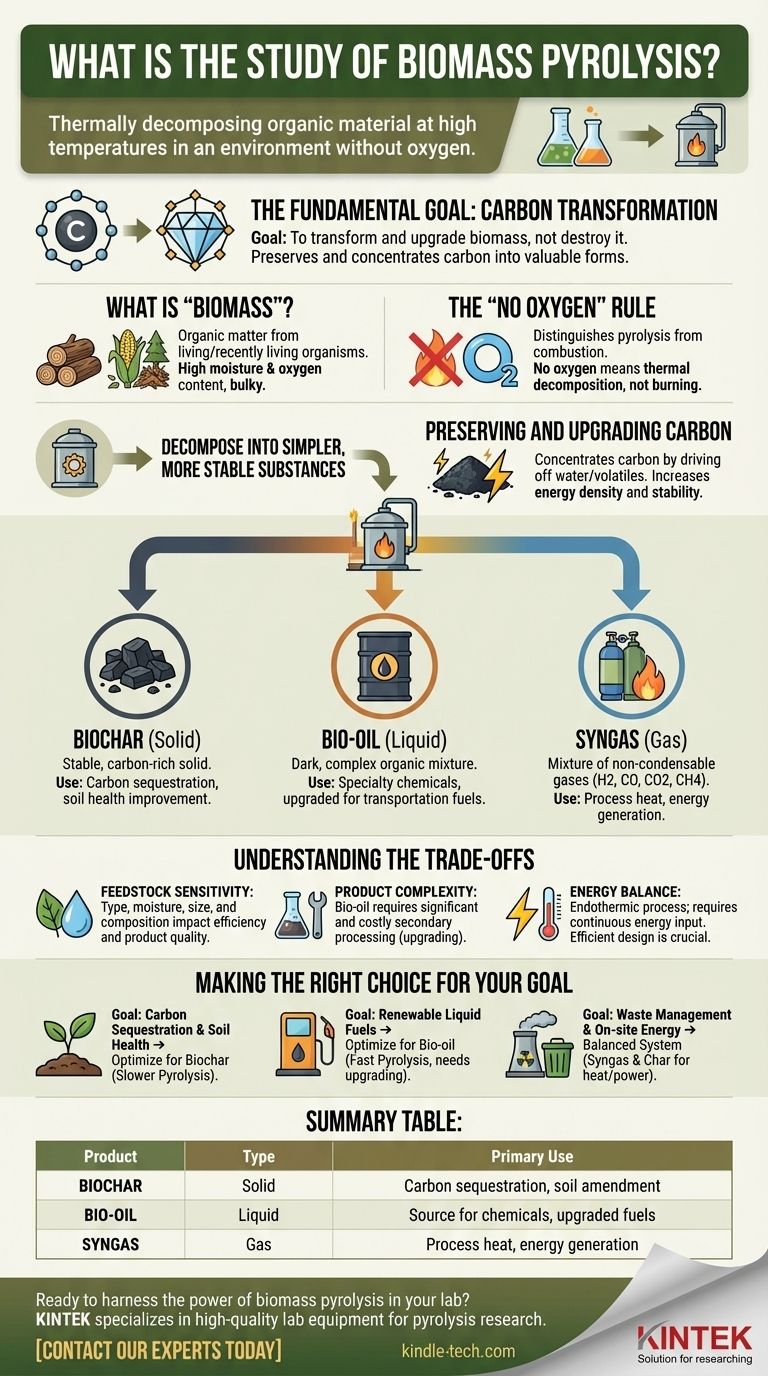

The Fundamental Goal: Carbon Transformation

Pyrolysis is a thermochemical conversion process. Understanding its core principles reveals why it is a powerful tool for waste valorization and renewable energy.

What is "Biomass"?

Biomass is any organic matter derived from living, or recently living, organisms. This includes wood, agricultural residues like corn stalks, forest debris, and even specific energy crops.

It is typically characterized by high moisture and oxygen content, which makes it bulky and inefficient to transport or use directly as a high-grade fuel.

The "No Oxygen" Rule

This is the single most important factor that distinguishes pyrolysis from combustion (burning).

In the presence of oxygen, biomass burns, releasing its energy as heat and converting its carbon into carbon dioxide.

In the absence of oxygen, the heat breaks the complex chemical bonds within the biomass, causing it to decompose into simpler, more stable substances without combusting.

Preserving and Upgrading Carbon

The ultimate objective is to retain as much of the original carbon as possible in a more useful state.

By driving off water and volatile organic compounds, the process concentrates the carbon. This significantly increases the energy density and stability of the final solid product.

The Three Primary Products of Pyrolysis

The decomposition of biomass does not yield a single output but a portfolio of products, each with different properties and applications. The relative yield of each product depends on the process conditions.

Biochar (Solid)

This is a stable, carbon-rich solid that resembles charcoal. It is often considered the main product, especially in slow pyrolysis processes. Biochar is valued for its ability to sequester carbon in soil for long periods and improve soil health.

Bio-oil (Liquid)

Also known as pyrolysis oil, this is a dark, dense liquid. It is a complex mixture of water and hundreds of different organic compounds derived from the breakdown of cellulose and lignin in the biomass. It can be a source for specialty chemicals or upgraded into transportation fuels.

Syngas (Gas)

This is a mixture of non-condensable gases, primarily hydrogen, carbon monoxide, carbon dioxide, and methane. Syngas is combustible and can be used to generate the heat required to power the pyrolysis process itself, making the system more energy-efficient.

Understanding the Trade-offs

While powerful, pyrolysis is not a perfect solution and involves key technical challenges and compromises. Its effectiveness is highly dependent on careful process control.

Feedstock Sensitivity

The process is highly sensitive to the type of biomass used. Its moisture content, physical size, and chemical composition directly impact the efficiency of the reaction and the quality of the end products.

Product Complexity

Bio-oil is not a "drop-in" replacement for petroleum. It is often acidic, corrosive, and chemically unstable, requiring significant and costly secondary processing (upgrading) before it can be used in conventional engines or refineries.

Energy Balance

Pyrolysis is an endothermic process, meaning it requires a continuous input of energy to maintain the high temperatures needed for decomposition. A poorly designed system can consume more energy than it produces from its outputs, defeating its purpose as a net energy producer.

Making the Right Choice for Your Goal

Understanding pyrolysis allows you to see it not as a single solution, but as a versatile platform technology. Your application will determine which aspect of the process is most important.

- If your primary focus is carbon sequestration and soil health: You will optimize for the production of high-quality, stable biochar through slower pyrolysis processes.

- If your primary focus is renewable liquid fuels: You will optimize for bio-oil production using fast pyrolysis, and you must account for the need for subsequent upgrading facilities.

- If your primary focus is waste management and on-site energy: You will design a balanced system where the syngas and char can be used to generate heat and power, effectively converting a waste liability into an energy asset.

Pyrolysis offers a sophisticated pathway to unlock the stored value in organic matter, turning potential waste into a portfolio of valuable resources.

Summary Table:

| Product | Type | Primary Use |

|---|---|---|

| Biochar | Solid | Carbon sequestration, soil amendment |

| Bio-oil | Liquid | Source for chemicals, upgraded fuels |

| Syngas | Gas | Process heat, energy generation |

Ready to harness the power of biomass pyrolysis in your lab? KINTEK specializes in high-quality lab equipment for pyrolysis research, helping you optimize biochar, bio-oil, and syngas production from various biomass feedstocks. Contact our experts today to find the perfect solution for your renewable energy or waste valorization project!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Vacuum Dental Porcelain Sintering Furnace

- Lab-Scale Vacuum Induction Melting Furnace

People Also Ask

- What role do laboratory autoclaves play in pectin extraction? Optimize Prebiotic Yield from Citrus and Apple Biomass

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing