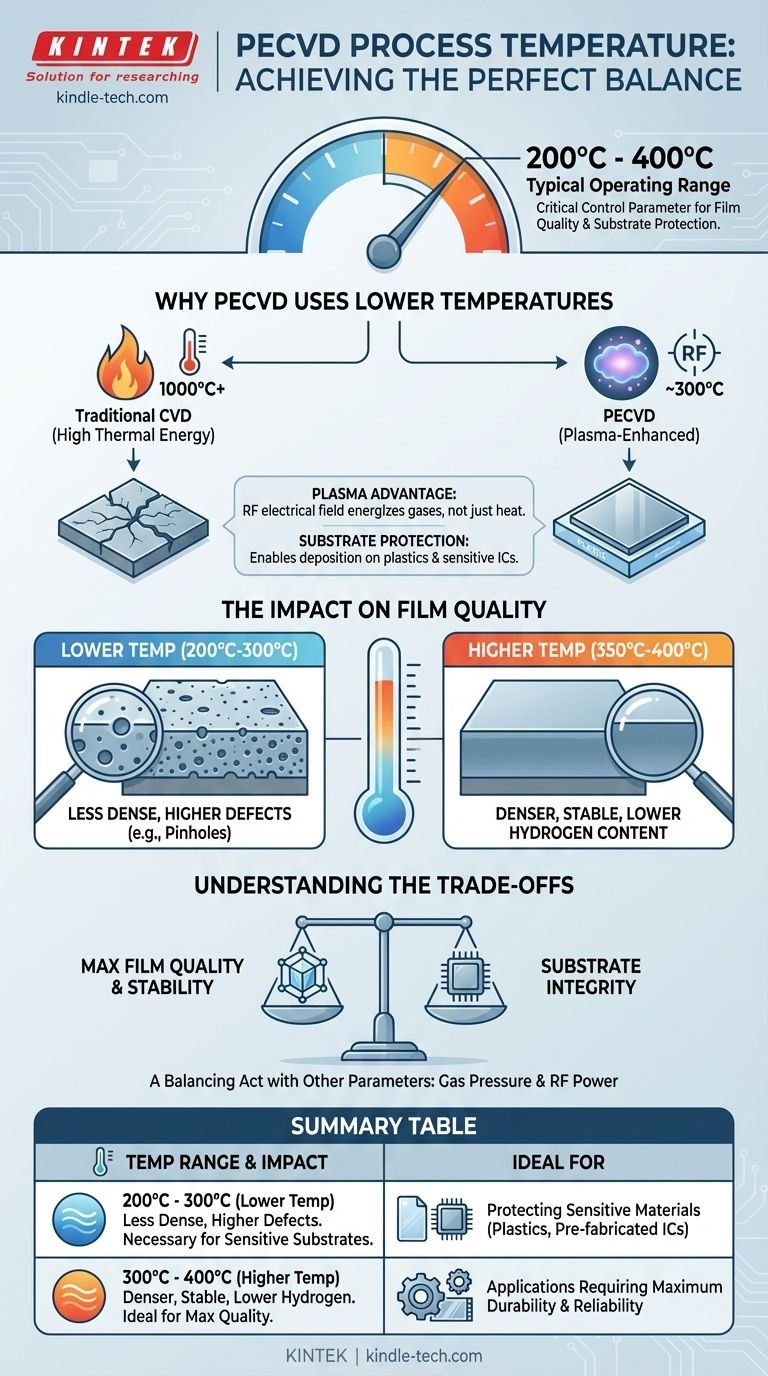

To be precise, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is typically carried out at temperatures between 200°C and 400°C. This relatively low temperature is the primary advantage of the process, especially when compared to traditional Chemical Vapor Deposition (CVD) methods that require much higher heat. However, this range is not absolute and is adjusted based on the specific film quality and substrate requirements of the application.

The specific temperature for a PECVD process is not a fixed number but a critical control parameter. It represents a fundamental trade-off between achieving the highest possible film quality and protecting the underlying substrate from thermal damage.

Why PECVD Uses Lower Temperatures

To understand the role of temperature, it's essential to first understand why PECVD is chosen over other deposition methods. The core innovation of the process is its use of plasma to energize the reactant gases.

The Plasma Advantage

In traditional CVD, high thermal energy (often over 1000°C) is required to break down the precursor gases and initiate the chemical reaction that forms the thin film.

In PECVD, an RF electrical field excites the gases into a plasma, a state of ionized gas. This plasma provides the energy needed for the reaction, allowing the process to occur at a much lower temperature.

Protecting Sensitive Substrates

The primary benefit of this lower operating temperature is the ability to deposit films on materials that cannot withstand high heat.

This makes PECVD invaluable for applications involving plastics, integrated circuits with previously fabricated layers, and other temperature-sensitive components where high-temperature processes would cause damage or diffusion.

The Impact of Temperature on Film Quality

While PECVD operates at low temperatures, the exact temperature selected within its typical range has a direct and significant impact on the final properties of the deposited film.

Higher Temperatures for Denser Films

Pushing the temperature toward the higher end of the PECVD range (typically 350°C to 400°C) generally results in a higher-quality film.

This increased thermal energy helps create a denser, more stable material with lower hydrogen content. These films are more robust and exhibit slower etch rates, indicating fewer structural defects.

Lower Temperatures and Potential Defects

Operating at the lower end of the temperature range is necessary for very sensitive substrates.

However, films deposited at lower temperatures can be less dense and may have a higher concentration of defects, such as pinholes. This is a direct consequence of providing less thermal energy to the atoms to settle into an optimal, low-defect structure.

Understanding the Trade-offs

The choice of temperature in PECVD is never made in a vacuum. It is a balancing act between competing priorities and works in concert with other process variables.

Film Quality vs. Substrate Integrity

This is the central trade-off. You must decide which is more critical: the absolute highest film quality or the preservation of the underlying device or material.

If the substrate can handle it, a higher temperature is almost always preferred for a more durable and reliable film.

The Role of Other Process Parameters

Temperature is only one piece of the puzzle. It works alongside other critical variables like gas pressure and RF power.

For example, a process run at a lower temperature might require adjustments to pressure or plasma power to compensate and achieve an acceptable deposition rate and film quality. These parameters together define the final outcome.

Choosing the Right Temperature for Your Process

Your specific goal will determine the ideal temperature within the PECVD operating window.

- If your primary focus is maximum film quality and stability: Operate at the highest temperature that your substrate and equipment can safely tolerate, often in the 350°C to 400°C range, to produce a dense film with low hydrogen content.

- If your primary focus is protecting a temperature-sensitive substrate: Use the lowest possible temperature that still yields a film with acceptable properties for your application, and be prepared to characterize and manage potential increases in defects.

- If you are working with extremely sensitive organic materials: You may need to investigate specialized variants like Plasma-Assisted Chemical Vapor Deposition (PACVD), which can operate at even lower temperatures, sometimes below 180°C.

Ultimately, selecting the correct temperature is a strategic decision that directly influences the performance and reliability of the final device.

Summary Table:

| Temperature Range | Primary Impact on Film | Ideal For |

|---|---|---|

| 200°C - 300°C | Lower density, higher defect potential | Protecting sensitive substrates (e.g., plastics, pre-fabricated ICs) |

| 300°C - 400°C | Denser, more stable films with lower hydrogen content | Applications requiring maximum film quality and durability |

Ready to optimize your PECVD process for superior thin film results?

At KINTEK, we specialize in providing high-performance lab equipment and consumables tailored to your specific deposition needs. Whether you're working with sensitive semiconductors or advanced materials, our experts can help you select the right PECVD system to achieve the perfect balance between film quality and substrate protection.

Contact us today to discuss how our solutions can enhance your laboratory's capabilities and drive your research forward.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- How does radio frequency (RF) power affect the PECVD process? Master Ionization for Superior Thin Film Quality

- What are the primary components of a PECVD system? Key Elements for High-Performance Thin Film Deposition

- Why must a rotating reaction vessel be utilized for MOF powders in PECVD? Achieve Uniform Material Modification

- What is the difference between CVD and plasma CVD? Unlock the Right Thin-Film Deposition Process

- How does post-treatment in an annealing furnace improve PECVD a-SiC thin films? Achieve Superior Material Stability

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- Is DLC coating scratch proof? Discover the Exceptional Scratch Resistance of DLC Coatings

- What are the different types of plasma deposition? Choose Between PVD Sputtering and PECVD