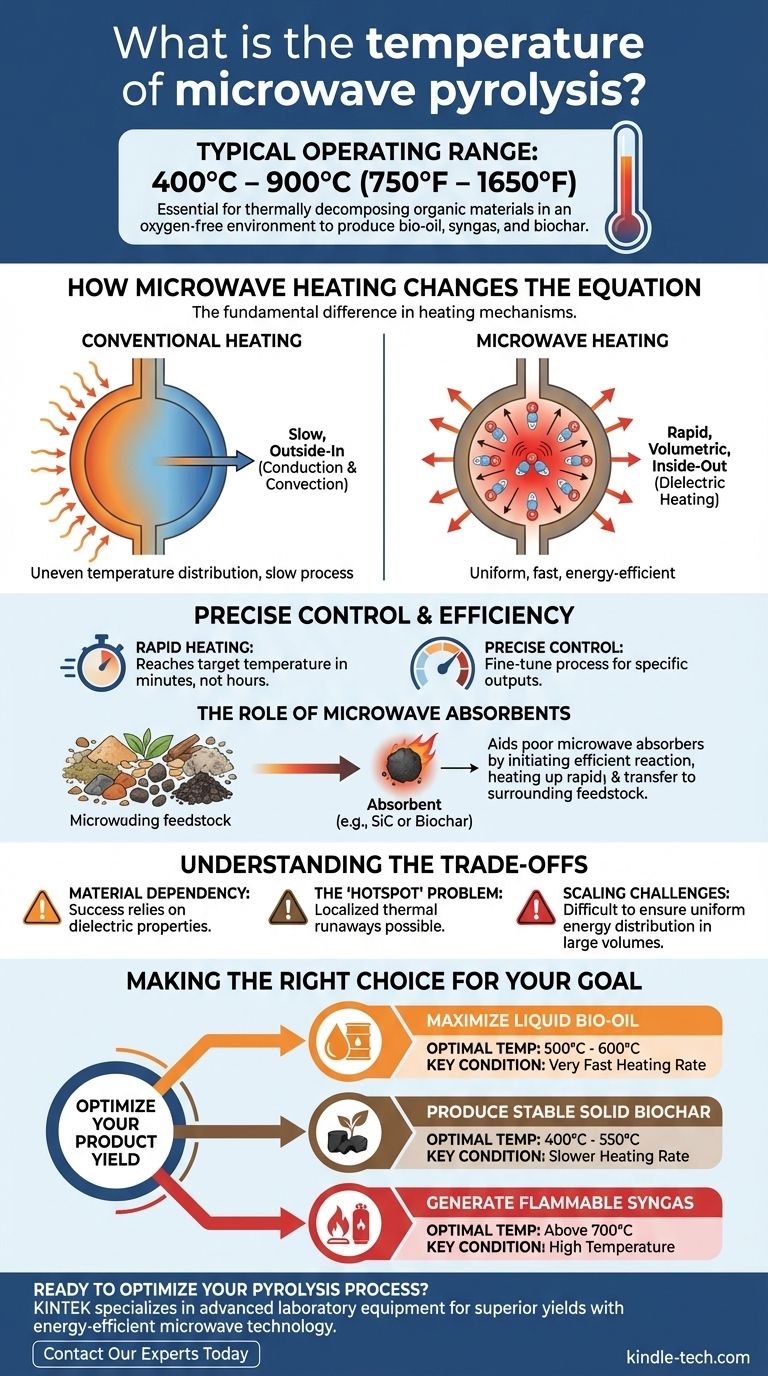

In short, microwave pyrolysis typically operates between 400°C and 900°C (750°F to 1650°F). This temperature range is necessary to thermally decompose organic materials like biomass or plastics in an oxygen-free environment. While the process can begin at lower temperatures around 200-300°C, the higher range is required to efficiently produce valuable outputs like bio-oil, syngas, and biochar.

The critical distinction is not the final temperature, which is similar to conventional methods, but how that temperature is achieved. Microwave pyrolysis heats materials from the inside-out, offering rapid and targeted energy delivery that fundamentally changes process control and efficiency.

How Microwave Heating Changes the Equation

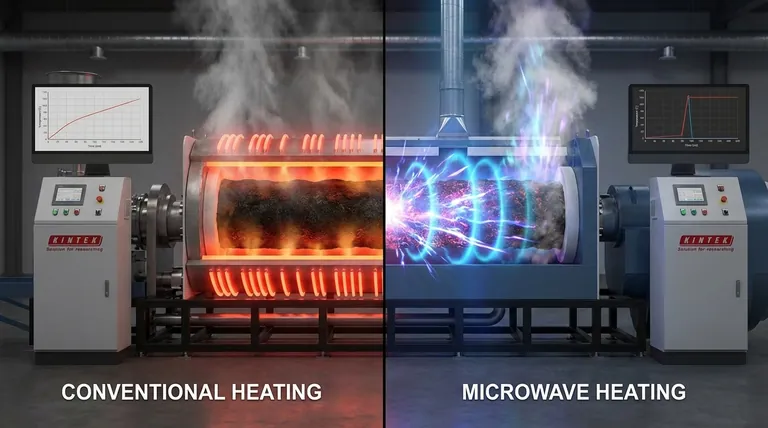

To grasp the significance of microwave pyrolysis, you must first understand the fundamental difference in heating mechanisms. Conventional methods are often slow and inefficient, while microwave heating is volumetric and immediate.

Conventional vs. Microwave Heating

Conventional pyrolysis relies on conduction and convection. Heat is applied to the outside of a reactor and slowly transfers inward to the feedstock, much like cooking a thick piece of meat in an oven. This process is slow and can lead to uneven temperature distribution.

Microwave pyrolysis uses dielectric heating. Microwaves directly energize polar molecules within the material, causing them to oscillate and generate heat internally and uniformly. This is an "inside-out" method that is significantly faster and more energy-efficient.

The Role of Microwave Absorbents

A key factor is that not all materials heat well with microwaves. Many types of biomass, for instance, are poor microwave absorbers.

To overcome this, a microwave-absorbent material (like silicon carbide or biochar from a previous run) is often mixed with the feedstock. This absorbent material heats up rapidly and then transfers that heat to the surrounding feedstock via conduction, initiating the pyrolysis reaction efficiently.

Precise and Rapid Temperature Control

Because the heating is generated directly within the material by an energy source that can be turned on or off instantly, microwave pyrolysis offers exceptional control.

Heating rates are extremely fast, allowing operators to reach the target temperature in minutes rather than hours. This precision enables fine-tuning of the process to favor the production of specific outputs, whether it's liquid bio-oil, solid biochar, or combustible syngas.

Understanding the Trade-offs

While innovative, microwave pyrolysis is not without its challenges. Understanding its limitations is crucial for practical application.

Material Dependency

The success of the process is highly dependent on the dielectric properties of the feedstock. Materials that don't absorb microwave energy well require the addition of an absorbent, which can add complexity and cost to the process.

The "Hotspot" Problem

While generally more uniform than conventional methods, microwave heating can still create localized thermal runaways or "hotspots." If not managed, these can lead to inconsistent product quality and potential damage to the reactor equipment.

Challenges in Scaling

Microwave technology is highly effective at lab and pilot scales. However, scaling it to large, industrial-level operations presents significant engineering and economic challenges, particularly in reactor design and ensuring even energy distribution across massive volumes of material.

Making the Right Choice for Your Goal

The optimal temperature within the 400-900°C range depends entirely on your desired end product. Microwave technology gives you the precise control to target these outcomes.

- If your primary focus is maximizing liquid bio-oil: A moderate temperature around 500-600°C with a very fast heating rate is typically most effective.

- If your primary focus is producing stable solid biochar: A lower temperature, often between 400-550°C, and a slower heating rate will maximize the solid yield.

- If your primary focus is generating flammable syngas: Higher temperatures, generally above 700°C, are required to further break down the materials into gaseous components.

Ultimately, microwave pyrolysis provides a powerful tool for controlling chemical decomposition through precise, volumetric heating.

Summary Table:

| Target Product | Optimal Temperature Range | Key Condition |

|---|---|---|

| Maximize Liquid Bio-Oil | 500°C - 600°C | Very Fast Heating Rate |

| Produce Stable Solid Biochar | 400°C - 550°C | Slower Heating Rate |

| Generate Flammable Syngas | Above 700°C | High Temperature |

Ready to optimize your pyrolysis process with precise temperature control? KINTEK specializes in advanced laboratory equipment, including pyrolysis systems. Our expertise can help you achieve superior yields of bio-oil, biochar, or syngas with energy-efficient microwave technology. Contact our experts today to discuss your specific application and goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Lab-Scale Vacuum Induction Melting Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- How does a rotary kiln rotate? Discover the Core Mechanics That Drive Thermal Processing

- What are the advantages of catalytic pyrolysis over thermal pyrolysis? Achieve Higher-Quality Bio-Oil and Chemicals

- What is pyrolysis decomposition of biomass? Unlock Value from Organic Waste

- What can be used for pyrolysis? Turning Organic Waste into Valuable Resources

- What are the advantages of pyrolysis in waste management? Turn Waste into Fuel and Valuable Resources

- What is pyrolytic decomposition? Transform Waste into Valuable Resources with Pyrolysis

- Does calcination produce CO2? Understanding the Role of Carbonates in Thermal Decomposition

- What are the essential features of the fast pyrolysis process? Maximize Bio-Oil Yield from Biomass