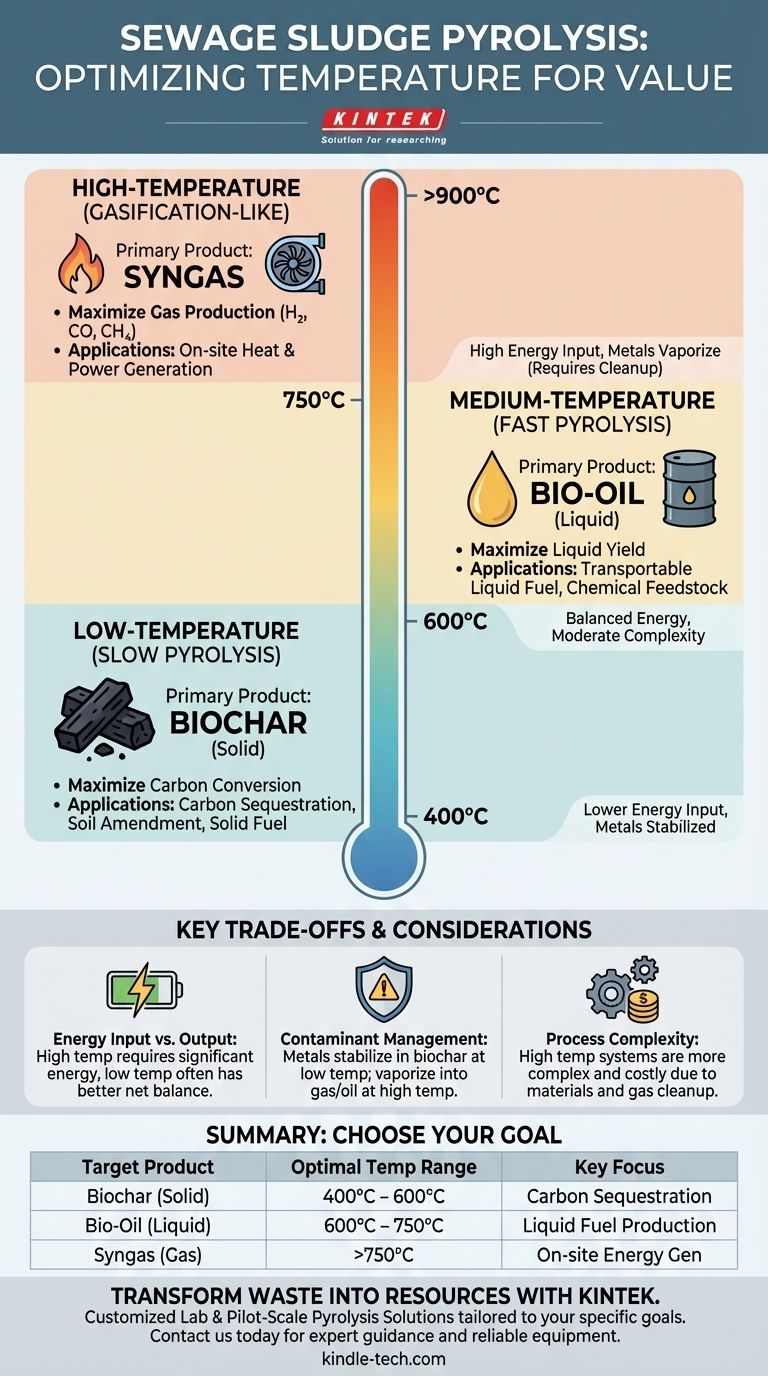

The temperature for sewage sludge pyrolysis is not a single value but rather a carefully selected range, typically between 400°C and 900°C. The specific temperature chosen is the most critical process parameter because it fundamentally dictates the yield and properties of the three primary products: solid biochar, liquid bio-oil, and combustible syngas.

The central challenge is not finding one "correct" temperature. It's understanding that lower temperatures favor biochar production, while higher temperatures maximize gas and liquid fuel yields. The optimal temperature is entirely dependent on your desired final product.

How Temperature Governs Pyrolysis Outcomes

Pyrolysis is the thermal decomposition of organic material, like sewage sludge, in a low-oxygen environment. Temperature is the primary lever that controls whether the sludge’s chemical bonds are broken down into solid, liquid, or gaseous components.

Low-Temperature Pyrolysis (400°C – 600°C)

This range is often associated with "slow pyrolysis," where heating rates are lower and residence times are longer. The primary output is a solid.

The main product is biochar, a stable, carbon-rich material. Operating in this range maximizes the conversion of the sludge's carbon into this solid form.

This biochar is valuable for carbon sequestration, as a soil amendment to improve water retention and nutrient availability, or as a solid fuel. Yields of bio-oil and syngas are significantly lower.

Medium-Temperature Pyrolysis (600°C – 750°C)

This intermediate range is often the target for "fast pyrolysis," which uses rapid heating to maximize the production of liquid fuels.

The main product is bio-oil (or pyrolysis oil). These temperatures and faster heating rates break down the organic matter into smaller, condensable vapors that are then cooled to form a liquid.

This process is ideal if the goal is to produce a liquid fuel that can be stored, transported, and potentially upgraded into transportation fuels or specialty chemicals.

High-Temperature Pyrolysis (>750°C)

Operating at these elevated temperatures drives the thermal cracking process even further, breaking down larger molecules—including the vapors that would form bio-oil—into small, non-condensable gas molecules.

The main product is syngas, a mixture of combustible gases like hydrogen (H₂), carbon monoxide (CO), and methane (CH₄).

This approach is essentially a form of gasification and is chosen when the primary goal is on-site heat and power generation, as the syngas can be combusted directly in a gas engine or turbine.

Understanding the Trade-offs

Selecting a temperature is an engineering decision that involves balancing competing priorities. There is no universally superior choice.

Energy Input vs. Energy Output

Achieving and maintaining higher temperatures requires a significant energy input. This operational cost must be justified by the energy value of the resulting syngas or bio-oil.

A lower-temperature process focused on biochar production often has a more favorable net energy balance, especially if the biochar is sold as a value-added product rather than used as a fuel.

Contaminant Management

Sewage sludge contains inorganic contaminants, including heavy metals. At lower pyrolysis temperatures (below 600°C), most of these metals remain stabilized within the solid biochar matrix.

At higher temperatures, some volatile metals (like mercury, cadmium, and lead) can vaporize and transfer into the bio-oil or syngas. This creates a downstream contamination issue that requires complex and costly gas cleanup systems.

Process Complexity and Cost

High-temperature systems demand more advanced and expensive reactor materials to withstand the harsh conditions.

Furthermore, the equipment needed to handle and upgrade corrosive bio-oil or to clean hot syngas adds significant complexity and cost compared to simply handling and processing solid biochar.

Selecting the Right Temperature for Your Goal

Your choice of pyrolysis temperature should be a direct reflection of your project's primary objective.

- If your primary focus is carbon sequestration or creating a soil amendment: Aim for slow pyrolysis in the 400-600°C range to maximize the yield and stability of biochar.

- If your primary focus is producing a transportable liquid fuel: Target fast pyrolysis conditions around 600-750°C to optimize the production of bio-oil.

- If your primary focus is on-site electricity or heat generation: Utilize high-temperature pyrolysis above 750°C to maximize the generation of energy-dense syngas.

By aligning the process temperature with your end goal, you can effectively transform sewage sludge from a waste stream into a valuable resource.

Summary Table:

| Target Product | Optimal Temperature Range | Key Process Focus |

|---|---|---|

| Biochar (Solid) | 400°C – 600°C | Slow pyrolysis for carbon sequestration & soil amendment |

| Bio-Oil (Liquid) | 600°C – 750°C | Fast pyrolysis for liquid fuel production |

| Syngas (Gas) | >750°C | High-temperature pyrolysis for on-site energy generation |

Ready to transform your sewage sludge into valuable resources?

At KINTEK, we specialize in advanced pyrolysis systems tailored to your specific goals. Whether you aim to maximize biochar for carbon sequestration, produce liquid bio-oil for fuel, or generate syngas for energy recovery, our expertise in lab equipment and consumables ensures you get the right solution for your laboratory or pilot-scale needs.

We provide:

- Customized pyrolysis reactors for precise temperature control.

- Expert guidance on process optimization to balance yield, energy efficiency, and contaminant management.

- Reliable equipment designed for durability and performance in demanding environments.

Contact us today to discuss how we can help you optimize your sewage sludge pyrolysis process. Let's turn your waste stream into a valuable resource. Get in touch via our contact form.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What are the advantages of using a rotary tube furnace for MoVOx catalysts? Elevate Uniformity and Crystallinity

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases

- Why are high temperatures required when sintering stainless steels? Unlock Pure, High-Density Results

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies