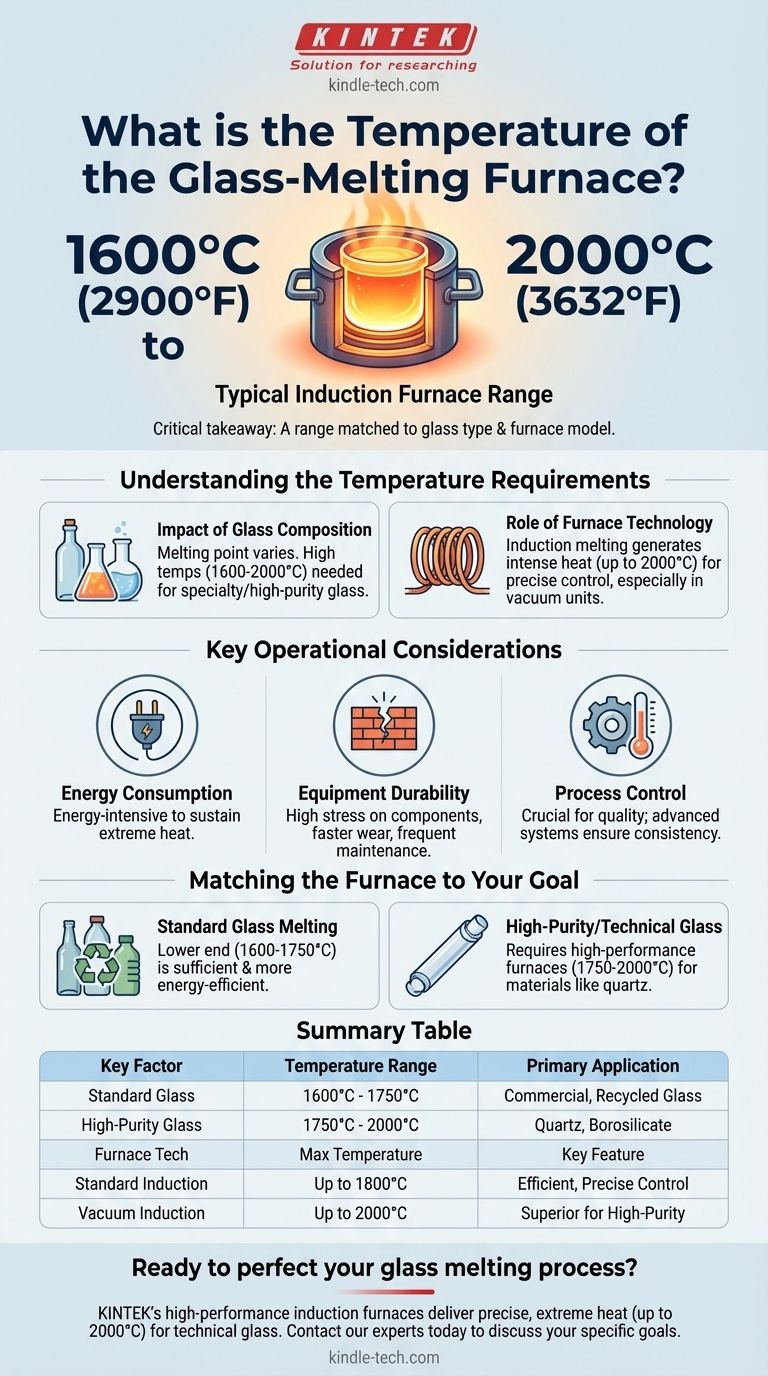

For a glass-melting application, an induction furnace operates at extremely high temperatures, with typical maximums ranging from 1600°C (2900°F) to 2000°C (3632°F). The specific temperature required within this range is dictated by the type of glass being melted and the specific model of the furnace, such as a standard or vacuum-assisted unit.

The critical takeaway is not a single temperature, but a temperature range. The furnace's capability must be matched to the specific melting point of the glass composition, with advanced induction furnaces providing the high heat needed for specialty materials.

Understanding the Temperature Requirements

The temperature inside a glass furnace is not arbitrary. It is a carefully controlled parameter that depends directly on the chemical composition of the material being melted and the capabilities of the heating technology employed.

The Impact of Glass Composition

Different types of glass have vastly different melting points. A furnace must be able to exceed this point to ensure the material becomes a homogenous, workable liquid (molten glass).

The high temperatures cited for induction furnaces, between 1600°C and 2000°C, are often necessary for melting specialty glasses with high-purity requirements or superior thermal resistance.

The Role of Furnace Technology

The references provided focus specifically on induction melting furnaces. This technology uses electromagnetic induction to generate intense heat directly within the metallic crucible or, in some cases, the conductive glass batch itself.

This method is highly efficient and allows for precise temperature control, making it possible to reach the upper-end temperatures of 2000°C, particularly in specialized configurations like vacuum induction furnaces.

Key Operational Considerations

Achieving and maintaining such high temperatures involves significant trade-offs that are critical to understand for any industrial or manufacturing process.

Energy Consumption

Reaching temperatures of 1600°C to 2000°C is an energy-intensive process. The primary operational cost of running such a furnace is often the electrical power required to sustain these extreme thermal conditions.

Equipment Durability

The intense heat places enormous stress on the furnace's components, especially the refractory lining that contains the molten material. Higher operating temperatures lead to faster wear and require more frequent maintenance and replacement.

Process Control

Maintaining a stable temperature is crucial for glass quality. Fluctuations can lead to defects in the final product. High-performance furnaces capable of reaching 2000°C rely on sophisticated control systems to ensure consistency.

Matching the Furnace to Your Goal

Choosing the right furnace temperature capability depends entirely on your end goal.

- If your primary focus is melting standard recycled or commercial glass: A furnace at the lower end of the high-temperature spectrum is typically sufficient and more energy-efficient.

- If your primary focus is producing technical or high-purity glass (e.g., quartz or borosilicate): You will need a high-performance furnace explicitly rated to reach and sustain temperatures in the 1600°C to 2000°C range.

Ultimately, selecting the correct furnace is about aligning the thermal capability of the equipment with the precise material science of your project.

Summary Table:

| Key Factor | Temperature Range | Primary Application |

|---|---|---|

| Standard Glass Melting | 1600°C - 1750°C | Commercial, recycled glass |

| High-Purity/Technical Glass | 1750°C - 2000°C | Quartz, borosilicate, specialty glasses |

| Furnace Technology | Max Temperature | Key Feature |

| Standard Induction Furnace | Up to 1800°C | Efficient, precise control |

| Vacuum Induction Furnace | Up to 2000°C | Superior for high-purity materials |

Ready to perfect your glass melting process?

KINTEK's high-performance induction furnaces are engineered to deliver the precise, extreme heat (up to 2000°C) required for technical and high-purity glass production. Our solutions offer superior temperature control, energy efficiency, and durability for your most demanding applications.

Contact our experts today to discuss how we can match the perfect furnace to your specific glass composition and production goals.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does induction furnace work? Achieve Fast, Clean, and Efficient Metal Melting

- What is induction furnaces based on the heating effect of? Unlock Faster, Cleaner Metal Melting

- What is levitation melting technique? Achieve Ultra-Pure Metal Melting Without Contamination

- How do you melt copper with induction? A Guide to Fast, Clean, and Controlled Melting

- What is the effect of frequency to induction hardening? Control Case Depth with Precision

- What is the induction furnace used for? Master Efficient Metal Melting & Heating

- What is the function of a vacuum induction arc furnace in AFA steel? Optimize Your High-Performance Alloy Synthesis

- What is a channel type induction furnace? A Guide to Efficient Metal Holding & Melting