To be precise, there is no single temperature range for the heat treatment of steel. The correct temperature is critically dependent on two factors: the specific type of steel alloy and the desired outcome, such as hardening, softening, or stress-relieving. Each process has its own unique temperature requirements, often calculated with precision based on the steel's carbon content.

The goal of heat treatment is not simply to heat steel, but to transform its internal crystal structure. The correct temperature is the one that achieves the necessary structural change—like forming austenite—for a specific process like annealing or hardening.

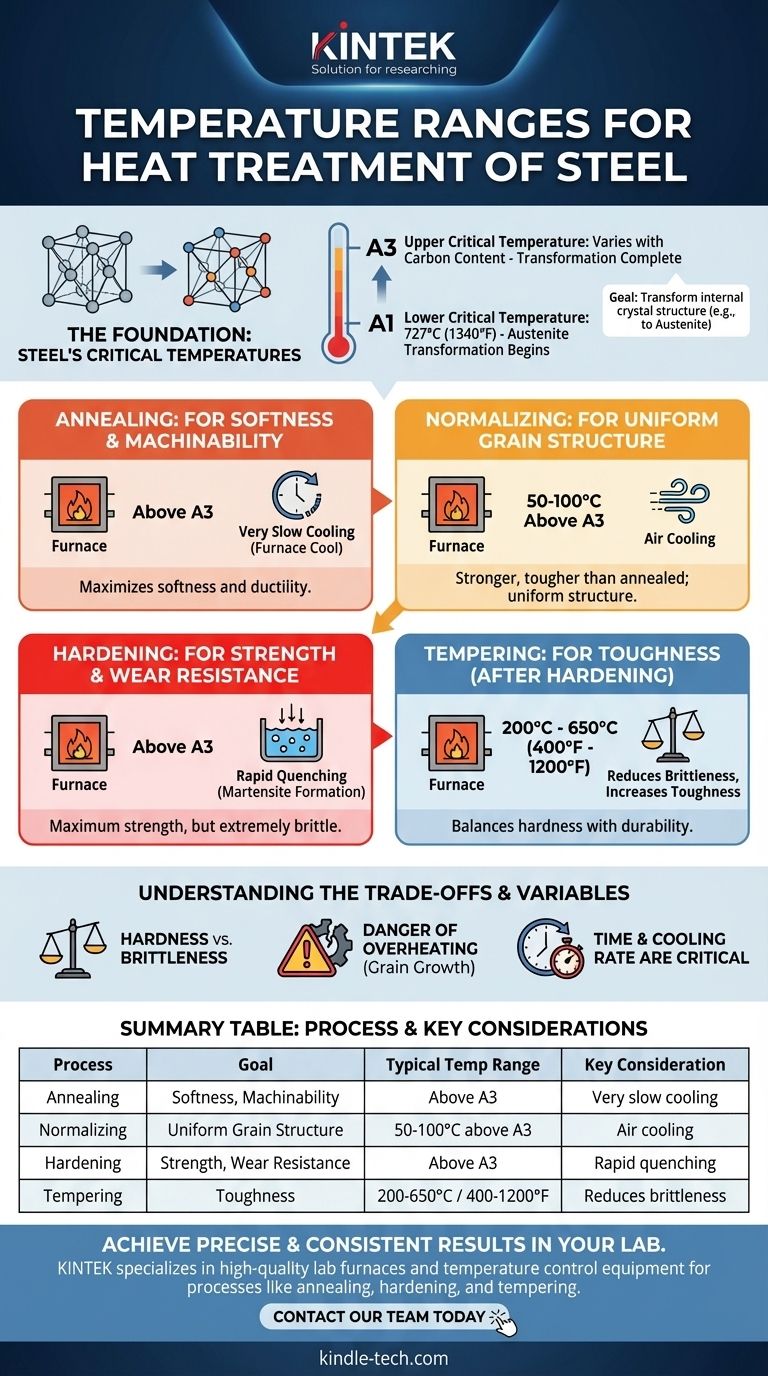

The Foundation: Steel's Critical Temperatures

To understand heat treatment, you must first understand that heating steel causes physical changes in its internal, crystalline structure. These changes occur at specific, predictable "critical temperatures."

The Lower Critical Temperature (A1)

The A1 temperature is the point at which the steel's structure begins to transform into a phase called austenite. For nearly all common carbon and alloy steels, this temperature is constant at 727°C (1340°F). Below this point, no significant hardening can occur.

The Upper Critical Temperature (A3)

The A3 temperature is the point at which the transformation to austenite is complete. Unlike the A1, this temperature varies significantly based on the steel's composition.

The Role of Carbon Content

The carbon content of the steel is the primary factor that determines the A3 temperature. As carbon content increases (up to 0.77%), the A3 temperature decreases. This is why a low-carbon steel requires a higher temperature for full hardening than a high-carbon steel.

Key Heat Treatment Processes and Their Temperatures

Different goals require different processes, each using the critical temperatures as a benchmark.

Annealing (For Softness and Machinability)

The goal of annealing is to make steel as soft and ductile as possible. This is done by heating the steel to just above its A3 temperature, holding it there long enough for the structure to fully transform (a process called "soaking"), and then cooling it extremely slowly, often by leaving it in the furnace to cool overnight.

Normalizing (For Uniform Grain Structure)

Normalizing creates a more uniform and fine-grained structure, resulting in steel that is stronger and tougher than annealed steel. It involves heating the steel to a slightly higher temperature than for annealing (typically 50-100°C above A3) and then letting it cool in still air.

Hardening (For Strength and Wear Resistance)

Hardening is used to make steel strong and wear-resistant. The steel is heated to above its A3 temperature to form austenite, then cooled so rapidly (a process called quenching) that the carbon atoms are trapped, forming an extremely hard and brittle structure called martensite.

Tempering (For Toughness)

Newly hardened steel is often too brittle for practical use. Tempering is a secondary, low-temperature treatment performed after hardening to reduce brittleness and increase toughness. It involves reheating the steel to a much lower temperature, typically between 200°C and 650°C (400°F and 1200°F), which sacrifices some hardness for a significant gain in toughness.

Understanding the Trade-offs

Choosing a heat treatment process is a matter of balancing properties. There is no single "best" state for steel.

Hardness vs. Brittleness

This is the most fundamental trade-off. The processes that create the highest hardness, like quenching, also create the most brittleness. Tempering is the act of deliberately managing this trade-off to meet the demands of a specific application.

The Danger of Overheating

Heating steel significantly above its required A3 temperature is a common and irreversible mistake. This causes excessive grain growth within the steel, resulting in a final product that is weak and brittle, even if the subsequent steps are performed correctly.

Temperature is Only One Variable

The peak temperature is critical, but it is not the only factor. The time the steel is held at that temperature (soaking) and the rate of cooling are just as important in determining the final properties of the material.

Selecting the Right Process for Your Goal

Your choice must be driven by the final application of the steel component.

- If your primary focus is maximum softness and machinability: Use full annealing by heating above A3 and ensuring a very slow cooling rate.

- If your primary focus is creating a uniform, strong starting structure: Use normalizing by heating above A3 and allowing the steel to air cool.

- If your primary focus is achieving maximum hardness: Use hardening by heating above A3 and quenching rapidly, but know that the result will be extremely brittle.

- If your primary focus is balancing hardness with toughness for a final part: Always follow a hardening process with tempering at a specific temperature to achieve the desired balance.

Ultimately, mastering heat treatment is about precisely using temperature to control steel's internal structure and achieve a specific engineering purpose.

Summary Table:

| Process | Goal | Typical Temperature Range | Key Consideration |

|---|---|---|---|

| Annealing | Softness, Machinability | Above A3 (Varies by alloy) | Very slow cooling (furnace cool) |

| Normalizing | Uniform Grain Structure | 50-100°C above A3 | Air cooling |

| Hardening | Strength, Wear Resistance | Above A3 | Rapid quenching required |

| Tempering | Toughness (after hardening) | 200°C - 650°C (400°F - 1200°F) | Reduces brittleness, increases toughness |

Achieve precise and consistent results in your lab. The correct heat treatment temperature is critical for achieving the desired material properties in your steel components. KINTEK specializes in high-quality lab furnaces and temperature control equipment, providing the reliability and precision your laboratory needs for processes like annealing, hardening, and tempering.

Let our expertise support your research and quality control. Contact our team today via our contact form to discuss your specific application and find the perfect furnace solution for your heat treatment requirements.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability