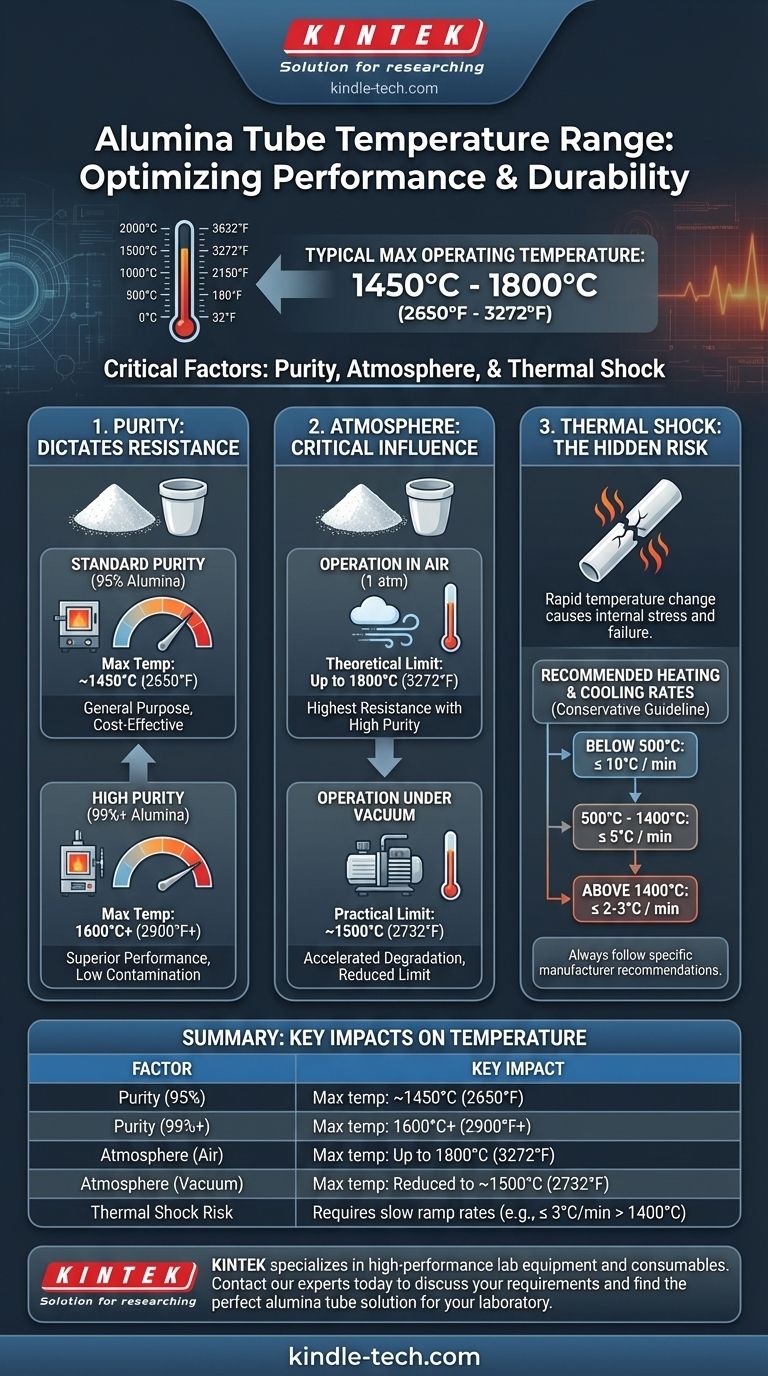

The maximum operating temperature of an alumina tube typically ranges from 1450°C to 1800°C (2650°F to 3272°F). However, this number is not absolute. The true service limit is critically dependent on the tube's purity, the operating atmosphere, and the rate at which it is heated and cooled.

The specific temperature an alumina tube can withstand is less about a single maximum value and more about a combination of factors. The most critical variables you must consider are the material's purity (95% vs. 99%+) and the pressure environment (air vs. vacuum).

Why Purity Dictates Temperature Resistance

The chemical composition of the alumina ceramic is the primary factor determining its performance at extreme temperatures. Minor impurities can significantly lower the material's melting point and structural integrity.

Standard Purity (95% Alumina)

Most general-purpose alumina tubes have a purity of around 95%. These are robust and cost-effective for applications with a maximum temperature of around 1450°C (2650°F).

High Purity (99%+ Alumina)

For more demanding applications, high-purity alumina (99% or greater) is required. This grade offers superior performance, pushing the service temperature up to 1600°C (2900°F) or higher. It is also essential when avoiding sample contamination is a priority.

The Critical Influence of Atmosphere

The environment inside the tube or furnace has a direct impact on the material's stability at high temperatures. The presence or absence of atmospheric pressure changes the operational limits.

Operation in Air (1 atm)

When used in a standard air atmosphere, alumina tubes exhibit their highest temperature resistance. Under these conditions, the theoretical limit can be as high as 1800°C (3272°F), assuming a very high-purity ceramic.

Operation Under Vacuum

Placing an alumina tube under a vacuum significantly reduces its maximum safe operating temperature. At high temperatures, a vacuum can accelerate material degradation. For this reason, the practical limit under vacuum is often lowered to around 1500°C (2732°F).

Understanding the Trade-offs: Thermal Shock

Simply reaching a high temperature is not the only challenge; the tube must survive the heating and cooling cycles. Alumina, like most ceramics, is brittle and highly susceptible to thermal shock.

The Danger of Rapid Temperature Change

Thermal shock occurs when different parts of the tube expand or contract at different rates due to rapid temperature changes. This creates immense internal stress that can easily cause the tube to crack or shatter.

Recommended Heating and Cooling Rates

To prevent failure, you must adhere to controlled heating and cooling schedules (ramp rates). The allowable rate decreases as the temperature increases.

A conservative guideline is:

- Below 500°C: ≤ 10°C per minute

- 500°C to 1400°C: ≤ 5°C per minute

- Above 1400°C: ≤ 2-3°C per minute

Always follow the specific recommendations provided by your furnace or tube manufacturer.

Making the Right Choice for Your Application

Selecting the correct tube requires matching the material's properties to your specific operational goal.

- If your primary focus is maximum temperature in air: Choose a high-purity (99%+) alumina tube and ensure your furnace controller is programmed for very slow ramp rates above 1400°C.

- If your primary focus is high-temperature vacuum operations: Select a high-purity tube but design your process to stay below the reduced limit of approximately 1500°C.

- If your primary focus is general purpose use below 1400°C: A standard 95% purity alumina tube is often the most suitable and cost-effective choice.

By understanding these key factors, you can select the appropriate material and implement procedures that ensure the longevity and reliability of your high-temperature processes.

Summary Table:

| Factor | Key Impact on Temperature Range |

|---|---|

| Purity (95% Alumina) | Max temp: ~1450°C (2650°F) |

| Purity (99%+ Alumina) | Max temp: 1600°C+ (2900°F+) |

| Atmosphere (Air) | Max temp: Up to 1800°C (3272°F) |

| Atmosphere (Vacuum) | Max temp: Reduced to ~1500°C (2732°F) |

| Thermal Shock Risk | Requires slow ramp rates (e.g., ≤ 3°C/min above 1400°C) |

Selecting the right alumina tube is critical for your lab's success. The precise temperature, atmosphere, and heating cycles of your application demand a tube that matches your specific needs. KINTEK specializes in high-performance lab equipment and consumables, offering a range of alumina tubes in various purities to ensure optimal results, longevity, and contamination control for your high-temperature processes.

Contact our experts today to discuss your requirements and find the perfect alumina tube solution for your laboratory.

Visual Guide

Related Products

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What are the advantages of using a horizontal tube furnace with quartz for FeCrAl oxidation? Ensure Purity and Precision

- What are the uses of ceramic tube? The Ultimate Guide for Extreme Environments

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- Why is a high-precision tube furnace required for CVD metal oxide films? Ensure Purity and Uniformity

- What is the role of a HPHT tube furnace in HTGR simulation? Achieve Precise Nuclear Environment Replications

- Can vacuum tubes be repaired? The Definitive Guide to Lifespan and Replacement

- How do industrial tube furnaces with PID controllers benefit terephthalic acid synthesis? Optimize Yield & Purity

- What technical advantages do quartz tube reactors offer for SCR denitration? Eliminate Wall Effects for Pure Data