The pyrolysis of wood does not have a single, universal temperature range. While the process begins at temperatures as low as 200°C, the ideal range depends entirely on the desired end product. The full operational spectrum for wood pyrolysis typically spans from 400°C to 900°C, with different temperatures yielding vastly different outputs.

The specific temperature used in wood pyrolysis is the most critical factor determining the final output. Lower temperatures and slower heating rates maximize solid biochar production, while higher temperatures favor the creation of liquid bio-oils and flammable gases.

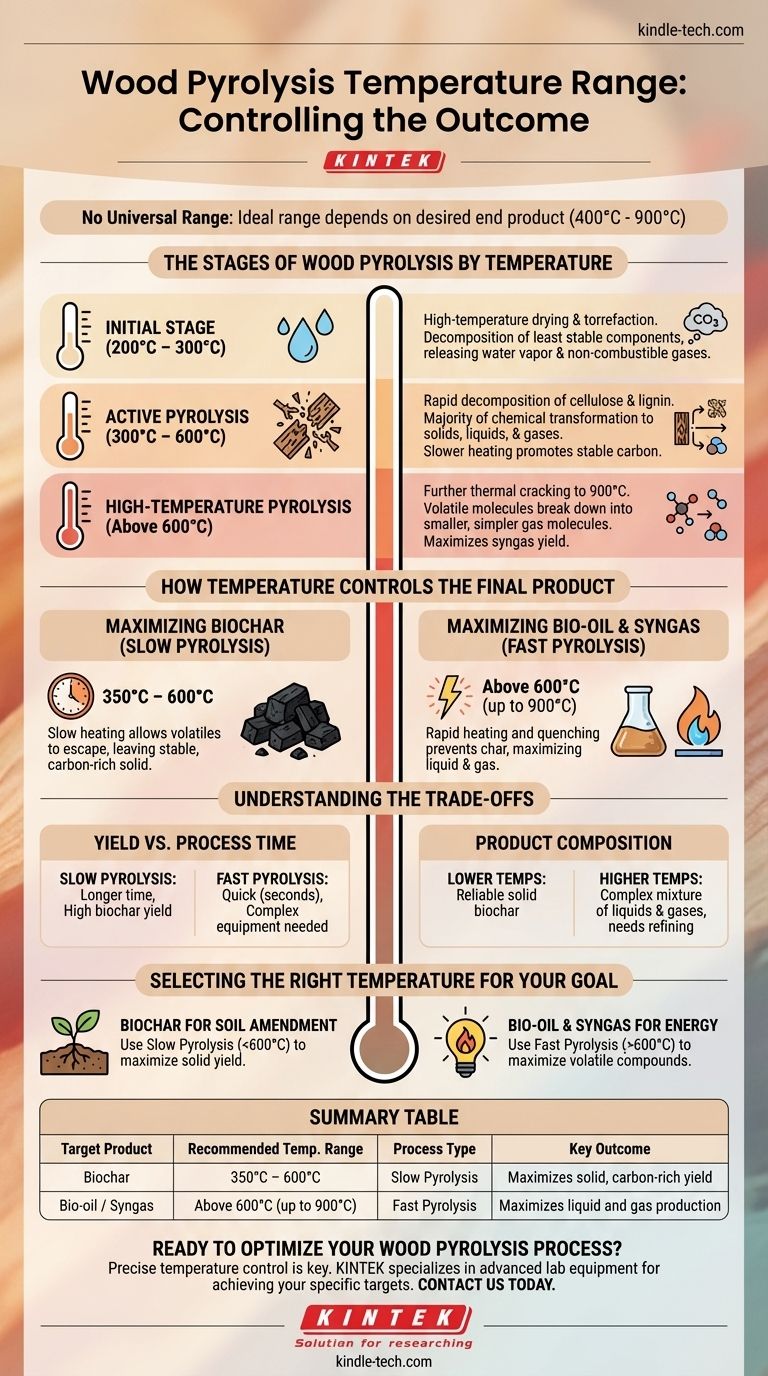

The Stages of Wood Pyrolysis by Temperature

Understanding how wood decomposes under heat reveals why temperature control is so crucial. The process isn't a single event but a series of overlapping stages.

The Initial Stage (200°C – 300°C)

Pyrolysis technically begins in this lower range. The least stable components of the wood start to break down, releasing water vapor and some non-combustible gases like carbon dioxide. This is essentially a high-temperature drying and torrefaction phase.

Active Pyrolysis (300°C – 600°C)

This is the core range where the primary structural components of wood, cellulose and lignin, rapidly decompose. The majority of the chemical transformation happens here, breaking down large organic polymers into a mix of solids, liquids, and gases. Slower heating within this range promotes the formation of stable carbon structures.

High-Temperature Pyrolysis (Above 600°C)

Pushing the temperature beyond 600°C and up to 900°C causes further thermal cracking. Large volatile molecules are broken down into smaller, simpler gas molecules. This range is used when the primary goal is to maximize the yield of combustible synthesis gas (syngas).

How Temperature Controls the Final Product

The choice of temperature is a deliberate decision to steer the chemical reactions toward a specific outcome. The rate of heating is just as important as the final temperature.

Maximizing Biochar (Slow Pyrolysis)

To produce the highest yield and quality of biochar, a slow pyrolysis process is used. The wood is heated gradually over a longer period, often at temperatures in the 350°C to 600°C range. This slow "cooking" allows volatile compounds to escape while leaving a stable, carbon-rich solid structure behind.

Maximizing Bio-oil and Syngas (Fast Pyrolysis)

To produce liquid bio-oil and flammable syngas, a fast pyrolysis process is required. This involves rapidly heating the wood to higher temperatures (typically 600°C to 700°C or more) in the absence of oxygen. The goal is to quickly vaporize the organic material and then rapidly cool the vapor to condense it into a liquid, preventing it from forming solid char.

Understanding the Trade-offs

Choosing a temperature range is an exercise in balancing competing priorities. There is no single "best" method; only the best method for a specific goal.

Yield vs. Process Time

Slow pyrolysis takes significantly longer but produces a high yield of high-quality biochar. Fast pyrolysis is very quick, often completing in seconds, but requires more complex equipment to handle the rapid heating and quenching of vapors.

Product Composition

Lower temperatures reliably produce solid biochar. Higher temperatures create a more complex mixture of liquids and gases that may require further costly refining before they can be used as fuel or chemical feedstock.

Selecting the Right Temperature for Your Goal

Your intended application is the only factor that should guide your choice of pyrolysis temperature.

- If your primary focus is creating high-quality biochar for soil amendment: Use a slow pyrolysis process with peak temperatures typically below 600°C to maximize the solid yield.

- If your primary focus is producing liquid bio-oil or combustible syngas for energy: Use a fast pyrolysis process at higher temperatures, generally above 600°C, to maximize the yield of volatile compounds.

Ultimately, controlling the temperature is how you control the outcome of wood pyrolysis.

Summary Table:

| Target Product | Recommended Temperature Range | Process Type | Key Outcome |

|---|---|---|---|

| Biochar | 350°C – 600°C | Slow Pyrolysis | Maximizes solid, carbon-rich yield |

| Bio-oil / Syngas | Above 600°C (up to 900°C) | Fast Pyrolysis | Maximizes liquid and gas production |

Ready to Optimize Your Wood Pyrolysis Process?

Whether your goal is high-yield biochar for soil enhancement or efficient bio-oil production for energy, precise temperature control is key. KINTEK specializes in advanced lab equipment and consumables, providing the reliable pyrolysis systems you need to achieve your specific product targets.

Contact us today to discuss how our solutions can enhance your laboratory's efficiency and output quality.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the disadvantages of a muffle furnace? Understanding the Trade-offs for Your Lab

- What are the materials used in a muffle furnace? A Guide to Durable Construction & Optimal Performance

- What is the temperature range of a furnace? From 1100°C to Over 2000°C Explained

- How did the design of muffle furnaces change with the advent of electric heating elements? The Evolution to Precision and Purity

- Does casting change material properties? Understand the Microstructural Impact on Performance