In most industrial applications, silicon carbide (SiC) exhibits exceptional temperature resistance, capable of operating reliably in air at temperatures reaching approximately 1,500°C (2,732°F). Its performance is not just about surviving this heat but maintaining its structural and chemical integrity under extreme thermal stress.

Silicon carbide's value extends far beyond a simple temperature rating. Its true strength lies in the combination of thermal stability, chemical inertness, and mechanical hardness, making it a uniquely resilient material for high-performance systems.

Why Silicon Carbide Excels in Extreme Heat

The ability of SiC to withstand such high temperatures is not an isolated feature. It is the direct result of a powerful set of underlying physical and chemical properties.

Exceptional Thermal Stability

Silicon carbide maintains its strength and form at temperatures where many metals would melt or deform. This structural integrity under load is critical for components like heating elements or furnace supports.

Low Thermal Expansion

SiC has a very small coefficient of thermal expansion. This means it expands and contracts very little when its temperature changes, giving it excellent resistance to thermal shock from rapid heating or cooling cycles.

Superior Chemical Inertness

High temperatures often accelerate chemical reactions and corrosion. Silicon carbide is extremely stable, showing strong resistance to acids and other corrosive agents, which prevents it from degrading in harsh chemical and thermal environments.

Understanding the Trade-offs and Practical Considerations

No material is without its practical limitations. Being an effective advisor means acknowledging the complete picture, including the specific characteristics that must be managed during design and operation.

Age-Related Resistance Increase

When used as a resistive heating element, the electrical resistance of silicon carbide will gradually increase over its operational life. High-quality systems account for this by using an auto-transformer with multiple taps to adjust the voltage and maintain consistent power output.

Inherent Brittleness

Like many advanced ceramics, silicon carbide is extremely hard but also brittle. While it resists wear and deformation, it can be susceptible to fracture from sharp, high-energy impacts. This requires careful consideration during handling, installation, and mechanical design.

Applications Driven by Temperature Resistance

The unique combination of these properties makes SiC the material of choice for applications where failure is not an option.

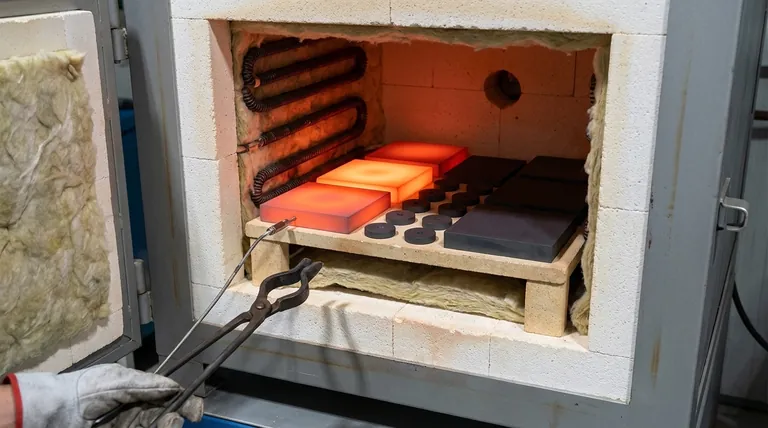

High-Temperature Heating Elements

The most common application is for electric furnace heating elements. SiC rods can operate for long periods at temperatures far exceeding the limits of traditional metallic elements, enabling processes in glass manufacturing, ceramics firing, and metal heat treatment.

Advanced Technical Components

Its resilience makes SiC invaluable in high-tech fields. It is used for components in semiconductor manufacturing equipment, nuclear energy systems, and aerospace applications where extreme heat, chemical exposure, and reliability are paramount.

Making the Right Choice for Your Application

To leverage silicon carbide effectively, align its properties with your primary engineering goal.

- If your primary focus is stable, long-term heating: Select SiC for its high temperature ceiling but ensure your system can compensate for the predictable, age-related increase in electrical resistance.

- If your primary focus is thermal shock resistance: SiC's low thermal expansion makes it an excellent choice for any application involving rapid and extreme temperature cycling.

- If your primary focus is mechanical and chemical durability: Use SiC for its hardness and inertness, but design the system to protect components from direct, sharp impacts.

By understanding both its remarkable strengths and its operational nuances, you can confidently deploy silicon carbide as a solution for the most challenging thermal environments.

Summary Table:

| Property | Key Characteristic | Benefit |

|---|---|---|

| Max Operating Temperature | Up to 1500°C (2732°F) in air | Enables high-temperature processes |

| Thermal Stability | Maintains strength and form at high heat | Reliable performance under load |

| Thermal Expansion | Very low coefficient | Excellent resistance to thermal shock |

| Chemical Inertness | High resistance to acids and corrosion | Longevity in harsh environments |

Need a reliable partner for high-temperature solutions?

KINTEK specializes in advanced lab equipment and consumables, including silicon carbide components for demanding thermal applications. Our expertise ensures you get the right materials and systems for processes like heat treatment, ceramics firing, and semiconductor manufacturing.

Let us help you enhance your lab's capabilities and reliability. Contact our experts today to discuss your specific needs and discover how our solutions can benefit your operation.

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why are alumina ceramic discs used as sample supports? Optimize Cathodic Cage Deposition Efficiency

- Is ceramic a good material? A Guide to Its Extreme Strengths and Trade-offs

- What is a substitute for ceramic? Find the Right Material for Your Application's Needs

- What are other names for ceramic powder? Classify by Composition, Size & Application

- What are the thermal properties of silicon carbide? Master Extreme Heat Management

- What is special about ceramic? Unmatched Durability Against Heat, Wear, and Chemicals

- What are the different types of silicon carbide? A Guide to Polytypes, Manufacturing, and Applications

- What are the advantages of SiC technology? Achieve Higher Efficiency and Power Density