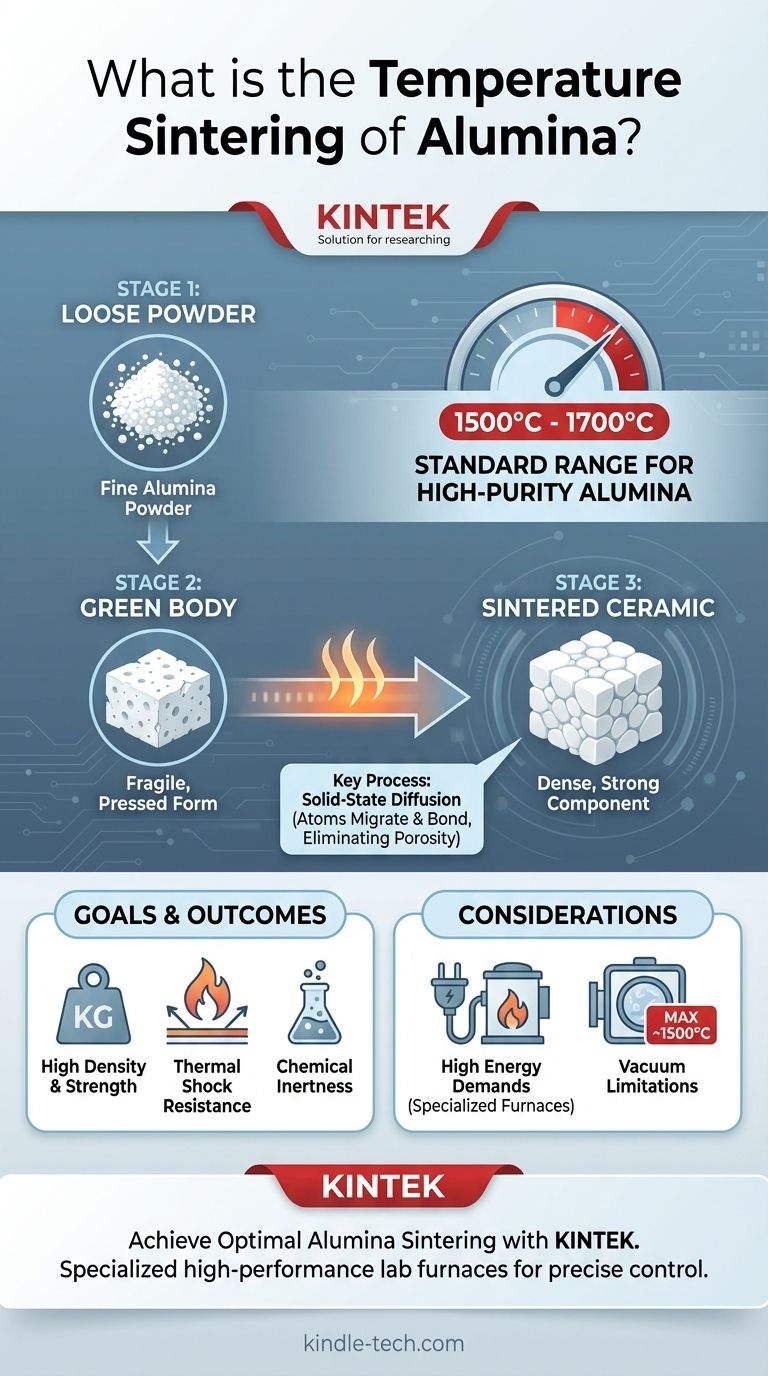

In standard practice, the sintering temperature for high-purity alumina typically falls within the range of 1500°C to 1700°C. This high-temperature process is essential for transforming loose alumina powder into a dense, strong ceramic component with the exceptional properties it is known for.

Sintering is not about melting; it's a thermal treatment that uses high heat to fuse ceramic particles together, eliminating porosity and creating a solid, durable material. For alumina, achieving this transformation requires extremely high temperatures, which directly dictates both its manufacturing complexity and its superior performance in demanding environments.

The Purpose of Sintering Alumina

Sintering is the fundamental process that gives alumina ceramics their strength and stability. Without it, you simply have a compressed powder with no structural integrity.

From Powder to Solid

The starting point for an alumina component is a fine powder. This powder is shaped, often by pressing, into a "green body" which is chalky and fragile. Sintering is the critical step that converts this green body into a hard, dense ceramic.

The Role of High Temperature

Heat provides the energy for atoms to migrate between the individual alumina particles. This process, known as solid-state diffusion, causes the particles to bond and grow together, gradually closing the gaps and pores between them.

The Goal: Full Densification

The primary objective of sintering is to achieve maximum density. A fully sintered alumina part has minimal internal porosity, which is what gives it high mechanical strength, chemical resistance, and thermal stability.

Defining the Sintering Temperature Range

The specific temperature required depends on several factors, but a well-established range exists for high-purity materials.

The Standard Range: 1500°C to 1700°C

For most high-purity alumina applications, holding the material within this temperature window is necessary to achieve full densification. This process occurs well below alumina's melting point of over 2000°C.

The Connection to Final Use

The high sintering temperature is directly related to the high service temperature of the final product. Components like alumina furnace tubes, which are sintered in this range, can then reliably operate at temperatures up to 1800°C.

Impact on Material Properties

Properly sintering alumina within this range is what unlocks its key characteristics:

- High Density and Strength: Minimizes weak points.

- Excellent Thermal Shock Resistance: Allows it to withstand rapid temperature changes.

- Acid and Alkali Resistance: Creates a non-porous surface that resists chemical attack.

Practical Considerations and Trade-offs

The high temperature required for sintering alumina has significant practical implications that must be considered.

Energy and Equipment Demands

Reaching and maintaining temperatures between 1500°C and 1700°C requires specialized, high-temperature furnaces. This makes the manufacturing process energy-intensive and costly compared to materials that can be processed at lower temperatures.

Vacuum Limitations

As noted in furnace specifications, the maximum operating temperature for alumina components is often lower under vacuum (around 1500°C). This is a critical consideration for applications involving vacuum furnaces, as it affects the usable life and integrity of the ceramic.

Applying This to Your Goal

Your approach depends on whether you are producing alumina parts or using them in a high-temperature application.

- If your primary focus is manufacturing alumina parts: You must use a furnace capable of precise control within the 1500°C to 1700°C range to ensure full densification and optimal material properties.

- If your primary focus is using alumina components: Recognize that their impressive service temperature (up to 1800°C) is a direct result of this demanding sintering process, which is why they are trusted for high-tech and industrial furnace applications.

Understanding the sintering process is key to appreciating both the challenges of producing alumina and the exceptional performance it delivers.

Summary Table:

| Key Factor | Details for Alumina Sintering |

|---|---|

| Standard Temperature Range | 1500°C to 1700°C |

| Primary Goal | Full densification via solid-state diffusion |

| Key Outcome | High mechanical strength, thermal shock resistance, chemical inertness |

| Critical Consideration | Requires specialized high-temperature furnaces; lower max temp (~1500°C) under vacuum. |

Achieve optimal alumina sintering results with KINTEK.

Whether you are manufacturing robust alumina components or require reliable alumina parts for your high-temperature applications, the right equipment is critical. KINTEK specializes in high-performance lab furnaces and consumables, providing the precise temperature control needed for sintering success.

Contact our experts today to discuss how our solutions can enhance your lab's capabilities and ensure the superior material properties you demand.

Visual Guide

Related Products

- Mesh belt controlled atmosphere furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

People Also Ask

- What is heat treatment used for casting? Enhance Strength, Durability, and Performance

- What are the process advantages of using a vacuum oven for RGO/PMMA nanocomposites? Enhance Density and Integrity

- What is the heat transfer of a vacuum oven? Mastering Radiation-Based Heating for Sensitive Materials

- Under what circumstances is Molybdenum-Lanthanum alloy used in hot zones? Enhance Durability & Resist Brittleness

- What is the sintering process of powder metallurgy? Transform Powder into Durable Metal Parts

- What are high temp furnaces made of? Graphite, Tungsten & Molybdenum Explained

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals

- Which furnace removes most air to prevent decarburization? The Definitive Guide to Vacuum Furnaces