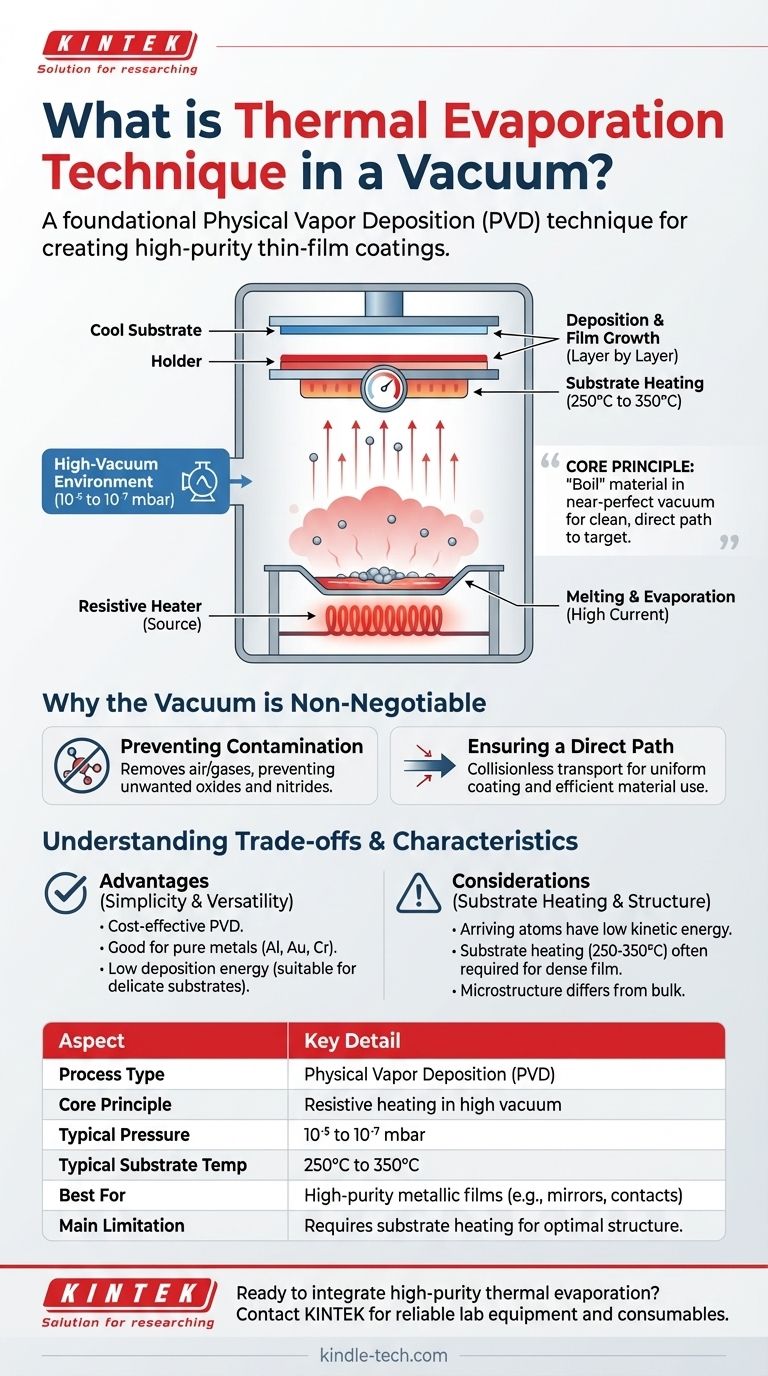

Thermal evaporation is a foundational thin-film deposition technique used to create highly pure coatings on a surface. It is a type of Physical Vapor Deposition (PVD) where a source material is heated within a high-vacuum chamber until it evaporates. This vapor then travels unimpeded through the vacuum and condenses onto a cooler substrate, forming a uniform, thin layer.

The core principle of thermal evaporation is to "boil" a material in a near-perfect vacuum. This vacuum is not just an environmental condition; it is a critical component that ensures the vaporized atoms have a clean, direct path to the target, preventing contamination and ensuring the quality of the final film.

The Core Mechanism: From Solid to Thin Film

Thermal evaporation, also known as resistive evaporation, follows a straightforward and highly controlled physical process. Each step is essential for building a high-quality film.

The Source Material and Heater

The process begins by placing the material to be deposited—often in the form of pellets, wire, or powder—into a container known as a source. This source can be a small ceramic crucible or a "boat" or "basket" made from a refractory metal like tungsten or molybdenum.

The Role of Electrical Resistance

This source is designed to have high electrical resistance. A high electrical current is passed directly through it, causing it to heat up rapidly, much like the filament in an incandescent light bulb. This is why the technique is often called resistive evaporation.

Melting and Evaporation

The intense heat from the source is transferred to the deposition material. As the temperature rises, the material first melts into a liquid and then begins to evaporate, releasing a stream of atoms or molecules into the chamber. This happens when the material's vapor pressure becomes significant.

Deposition onto the Substrate

These vaporized atoms travel in straight, line-of-sight trajectories through the vacuum chamber. They eventually strike a cooler substrate (the object being coated) that is strategically placed above or near the source. Upon contact, the atoms lose their thermal energy, condense back into a solid state, and build up layer by layer to form a thin film.

Why the Vacuum is Non-Negotiable

The entire process must occur in a high-vacuum environment. The quality of this vacuum is directly linked to the quality of the resulting film.

Preventing Contamination

A vacuum chamber is pumped down to extremely low pressures (typically 10⁻⁵ to 10⁻⁷ mbar) to remove virtually all air and other gaseous contaminants. Without this, the hot, reactive vapor stream would immediately collide with oxygen and nitrogen, forming unwanted oxides and nitrides within the film.

Ensuring a Direct Path

The vacuum creates an environment of collisionless transport. By removing air molecules, it provides a clear, unobstructed path for the vaporized atoms to travel from the source to the substrate. This ensures a uniform coating and efficient use of the source material.

Understanding the Trade-offs and Characteristics

While effective, thermal evaporation is a technique with specific strengths and limitations that make it suitable for certain applications over others.

Simplicity and Versatility

One of the primary advantages of thermal evaporation is its relative simplicity and cost-effectiveness compared to other PVD methods. It is highly effective for depositing a wide range of materials, particularly pure metals and simple alloys, achieving films with good purity and adhesion.

Low Deposition Energy

The atoms in thermal evaporation travel with only their thermal energy, which is quite low. This means they arrive at the substrate with less kinetic energy compared to atoms in a process like sputtering. This can be an advantage for coating delicate substrates.

The Need for Substrate Heating

A consequence of low deposition energy is that the arriving atoms may not have enough energy to form a dense, well-structured film on their own. To overcome this, the substrate is often heated to between 250°C and 350°C. This added energy allows the atoms to move around on the surface and settle into a more stable structure.

Microstructure Differences

It is critical to understand that the deposited film's microstructure can be widely different from the bulk material that was evaporated. The low energy and vacuum conditions create a unique growth environment, which must be accounted for when specific material properties are required.

When to Choose Thermal Evaporation

Selecting the right deposition technique depends entirely on your project's goals, materials, and budget.

- If your primary focus is cost-effectiveness for pure metals: Thermal evaporation is an excellent choice for depositing high-purity metallic films like aluminum, gold, or chrome for applications such as mirrors and electrical contacts.

- If you are working with heat-sensitive substrates: The low-energy nature of the vapor stream can be beneficial, but you must consider if the substrate can tolerate the required heating to ensure good film quality.

- If achieving a specific crystalline structure is critical: Be prepared to carefully control process parameters like substrate temperature and deposition rate, and recognize that other PVD methods may offer more direct control over the film's final properties.

Ultimately, thermal evaporation is a powerful and accessible technique for creating high-quality thin films when its operational principles and limitations are correctly applied.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Principle | Resistive heating of a material in a high vacuum to create a vapor that condenses on a substrate. |

| Typical Pressure | 10⁻⁵ to 10⁻⁷ mbar |

| Typical Substrate Temp | 250°C to 350°C |

| Best For | Cost-effective deposition of pure metals (e.g., Al, Au) for mirrors, electrical contacts. |

| Main Limitation | Low deposition energy may require substrate heating for optimal film density and structure. |

Ready to integrate high-purity thermal evaporation into your lab workflow?

At KINTEK, we specialize in providing reliable lab equipment and consumables for all your thin-film deposition needs. Whether you are developing new electronic components, optical coatings, or advanced materials, our expertise and product range can help you achieve precise and consistent results.

Let's discuss your project. Contact our experts today to find the perfect thermal evaporation solution for your laboratory.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition