In short, the coefficient of thermal expansion (CTE) for Silicon Carbide (SiC) is approximately 4.0 x 10⁻⁶ per degree Celsius (°C). This value is significantly lower than that of most metals and many other ceramics, a critical factor that defines its behavior in high-temperature applications. This low expansion is a primary reason for SiC's exceptional performance and a key consideration in engineering design.

Understanding thermal expansion is not just about knowing a number; it's about predicting how a material will behave under thermal stress. SiC's low and stable expansion is its greatest asset for thermal shock resistance but also presents its biggest design challenge when joined with other materials.

A Deeper Look at Thermal Expansion in SiC

To properly design with Silicon Carbide, especially in the high-temperature environments where it excels, we must move beyond the single CTE value and understand its implications.

What the CTE Value Means

The coefficient of thermal expansion describes how much a material changes in size for every degree of temperature change. A low CTE, like that of SiC, means the material expands and contracts very little when heated or cooled.

This property stems directly from the strong covalent bonds between silicon and carbon atoms in its crystal lattice. These bonds are incredibly rigid and resist the increased atomic vibration that comes with higher temperatures, resulting in minimal dimensional change.

How SiC Compares to Other Materials

Context is everything. Placing SiC's expansion behavior alongside other common engineering materials reveals why it is both so useful and so challenging.

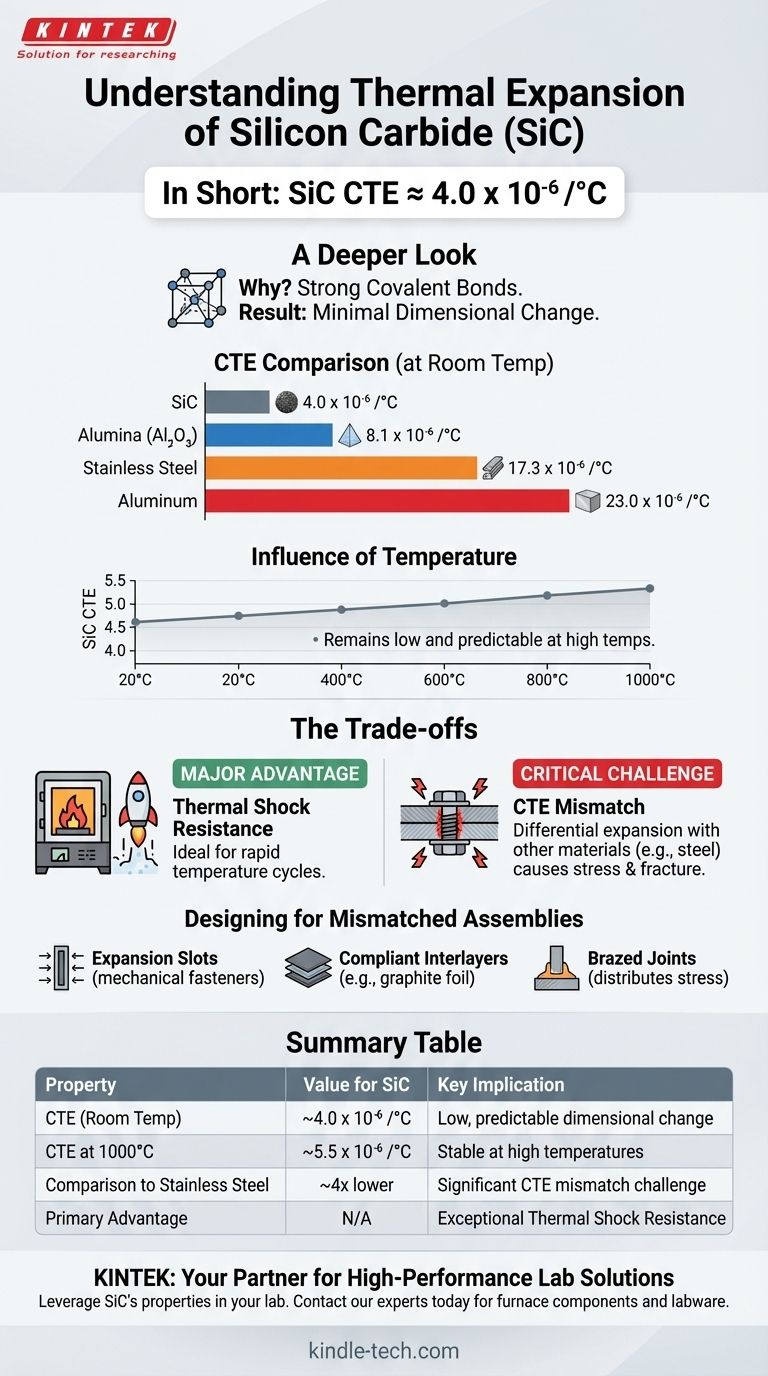

- Silicon Carbide (SiC): ~4.0 x 10⁻⁶ /°C

- Alumina (Al₂O₃): ~8.1 x 10⁻⁶ /°C

- Stainless Steel: ~17.3 x 10⁻⁶ /°C

- Aluminum: ~23.0 x 10⁻⁶ /°C

As you can see, stainless steel expands more than four times as much as SiC for the same temperature change. This difference is the root of most thermal-mechanical challenges.

The Influence of Temperature on Expansion

The CTE of SiC is not perfectly constant; it increases slightly as temperature rises. While its value is around 4.0 x 10⁻⁶ /°C at room temperature, it may increase to around 5.5 x 10⁻⁶ /°C at 1000°C.

Even at these elevated temperatures, its expansion remains remarkably low and predictable compared to metals, contributing to its dimensional stability in furnaces, heat exchangers, and other extreme environments.

Understanding the Trade-offs

The low CTE of Silicon Carbide is a double-edged sword. It creates significant advantages in some areas and requires careful engineering to manage in others.

The Major Advantage: Thermal Shock Resistance

Thermal shock occurs when a material is heated or cooled so rapidly that different parts of it expand or contract at different rates, creating internal stress that can cause it to crack.

Because SiC expands so little, the internal stresses generated during rapid temperature changes are much lower than in other materials. Combined with its high thermal conductivity, this gives SiC world-class thermal shock resistance, making it ideal for applications like kiln furniture and rocket nozzles.

The Critical Challenge: CTE Mismatch

The most common failure mode for SiC components is not from the material itself, but from the stress induced by other materials attached to it.

Imagine a SiC plate bolted to a steel frame. As the assembly heats up, the steel frame tries to expand four times more than the SiC. Since the SiC is rigid and brittle, this differential expansion places immense tensile or shear stress on the ceramic, which can easily lead to fracture.

Designing for Mismatched Assemblies

Successfully integrating SiC into a multi-material system requires designing specifically to accommodate this expansion difference. Strategies include using mechanical fasteners with expansion slots, incorporating compliant interlayers (like graphite foil), or designing brazed joints that distribute stress over a larger area.

Making the Right Choice for Your Goal

Your design approach should be dictated by your primary engineering objective.

- If your primary focus is high-temperature dimensional stability: Choose SiC for its low, predictable expansion, but ensure you design any interfaces with higher-expansion materials to prevent mechanical stress.

- If your primary focus is surviving rapid temperature cycles: Leverage SiC's low CTE and high thermal conductivity as a core advantage, as it vastly outperforms most other ceramics and metals in thermal shock resistance.

- If your primary focus is joining SiC to metal components: You must prioritize designs that accommodate differential expansion, such as using flexible joints, bellows, or graded interlayers to avoid catastrophic failure.

Mastering the implications of Silicon Carbide's thermal expansion is fundamental to unlocking its exceptional performance in the most demanding applications.

Summary Table:

| Property | Value for SiC | Key Implication |

|---|---|---|

| Coefficient of Thermal Expansion (CTE) | ~4.0 x 10⁻⁶ /°C | Low, predictable dimensional change with temperature |

| CTE at 1000°C | ~5.5 x 10⁻⁶ /°C | Remains low and stable at high temperatures |

| Comparison to Stainless Steel | ~4x lower | Creates significant CTE mismatch in assemblies |

| Primary Advantage | Exceptional Thermal Shock Resistance | Ideal for rapid temperature cycles |

Ready to leverage the exceptional thermal properties of Silicon Carbide in your lab?

At KINTEK, we specialize in high-performance lab equipment and consumables. Our expertise in materials like SiC ensures you get the right solutions for applications requiring superior thermal shock resistance and dimensional stability, from furnace components to specialized labware.

Let's discuss how SiC can solve your high-temperature challenges. Contact our experts today for a consultation!

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

People Also Ask

- What is the maximum temperature for a ceramic tube? Find the Right Material for Your High-Temp Needs

- What temperature is alumina fired at? Unlock the Key to Perfect Ceramic Sintering

- Why can high-porosity High-Entropy Ceramic insulation be synthesized via in-situ reaction? Efficient & Pure Solutions

- What is the maximum temperature for ceramics? Find the Right Material for Your High-Temp Application

- What are the useful applications of ceramics? Unlock High-Performance Solutions for Your Industry

- Why are Beta-Al2O3 pellets covered with powder during sintering? Master Volatility Control for Better Ceramics

- What is the primary function of porous ceramic supports? Ensuring Structural Integrity in Zeolite Membranes

- How do ceramic insulators contribute to SHS experimental safety? Enhance Your Lab’s Ignition Precision and Protection