In essence, pyrolysis fuel is a versatile substitute for conventional industrial fuel oil. It is most commonly used for heating and power generation in stationary applications like industrial boilers, furnaces, and electrical generators. Industries such as steel, ceramics, and chemical production utilize it as an alternative energy source derived from waste materials.

While often seen as a direct fuel, pyrolysis oil is more accurately understood as one component of a larger waste-to-value system. Its practical application is currently limited by quality issues, making its potential as a refinery feedstock or part of a multi-product system (alongside biochar and syngas) its most promising future.

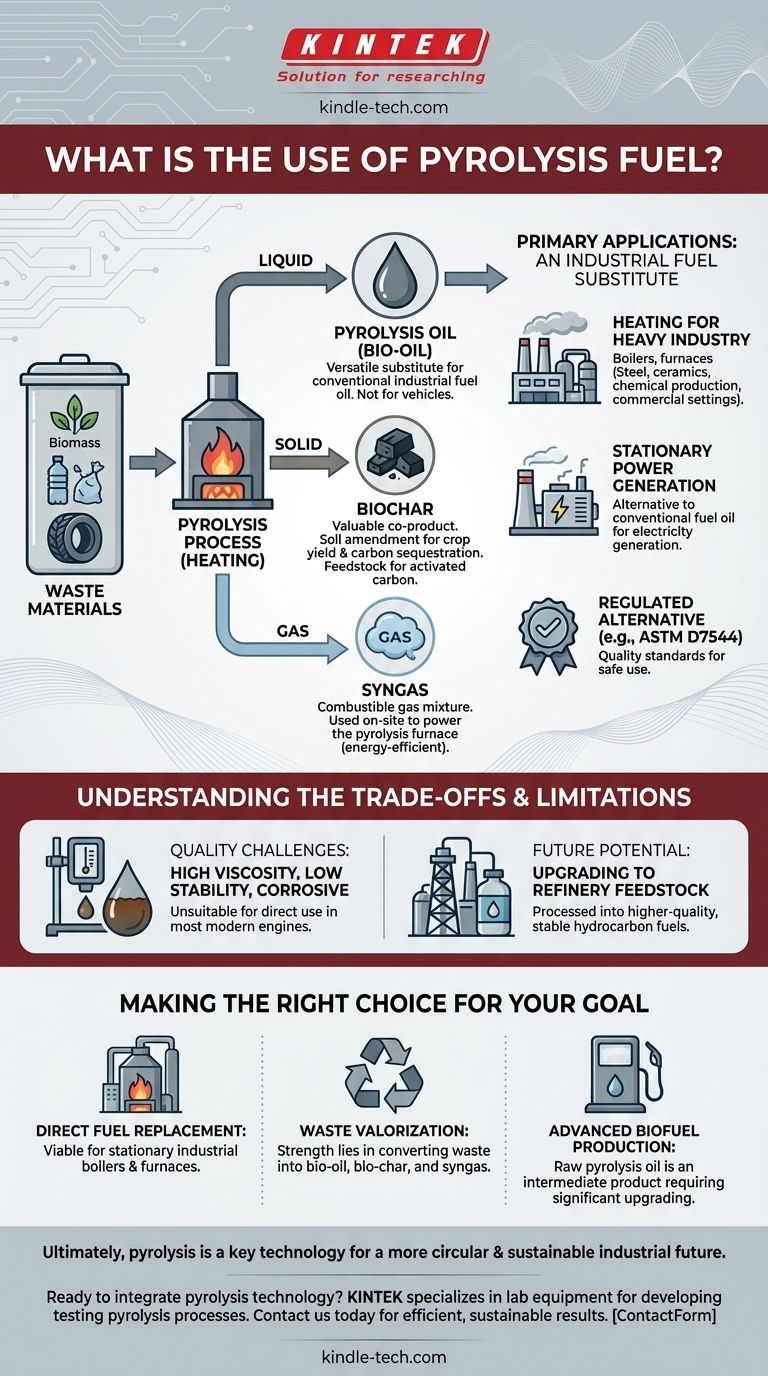

Primary Applications: An Industrial Fuel Substitute

Pyrolysis fuel, often called bio-oil or pyrolysis oil, fills a specific niche in the energy market. It is not a drop-in replacement for gasoline or diesel in consumer vehicles but serves as a substitute for heavier, less-refined fossil fuels.

Heating for Heavy Industry

The primary use for pyrolysis oil is as a combustion fuel in large-scale heating applications.

This includes furnaces and boilers in steel and iron factories, ceramic manufacturing, and various chemical industries. It can also be used in commercial settings like large hotels or restaurants with industrial boilers.

Stationary Power Generation

Another key application is the generation of electricity.

Pyrolysis oil can be used in certain types of generators and large power plants as an alternative to conventional fuel oil, helping to power industrial facilities or contribute to the electrical grid.

A Regulated Alternative

In stationary applications, the use of pyrolysis oil is governed by established standards, such as ASTM D7544. This regulation provides a framework for quality and ensures it can be used safely and effectively in compatible equipment.

Beyond Fuel Oil: The Full Value of Pyrolysis

Viewing pyrolysis as a process that creates only liquid fuel is an incomplete picture. The method inherently produces three distinct products from a single feedstock, each with its own value.

The Three Key Products

Pyrolysis breaks down source material (like biomass or plastic waste) into pyrolysis oil (the liquid fuel), biochar (a solid, charcoal-like substance), and syngas (a mixture of combustible gases).

Bio-char: A Valuable Co-Product

Bio-char is not waste; it is a valuable material used as a soil amendment to improve crop yields and for carbon sequestration. It can also serve as a feedstock to produce activated carbon for filtration systems.

Syngas: On-Site Energy

The syngas produced during the process is typically captured and used as fuel to power the pyrolysis furnace itself. This creates a more energy-efficient, self-sustaining operation and reduces reliance on external energy sources.

Understanding the Trade-offs and Limitations

While promising, pyrolysis oil has significant technical challenges that currently limit its widespread adoption as a direct fuel source.

The Challenge of Quality

Pyrolysis oil is fundamentally different from refined petroleum. It tends to have high viscosity, low stability (degrading over time), and can be corrosive to standard engine parts and fuel lines.

These properties make it unsuitable for direct use in most modern diesel engines without significant modification or pre-treatment of the fuel.

The Path of Upgrading

Because of these quality issues, a major potential application is not direct use, but as an intermediate feedstock. The crude pyrolysis oil can be sent to a refinery for upgrading, where it is processed further to create higher-quality, stable hydrocarbon fuels.

Feedstock and Sustainability

The viability and environmental impact of pyrolysis fuel depend heavily on the source material. Using agricultural waste or non-recyclable plastics supports a circular economy, while using crops grown specifically for fuel can raise sustainability concerns.

Making the Right Choice for Your Goal

The best use of pyrolysis depends entirely on your strategic objective.

- If your primary focus is direct fuel replacement: Pyrolysis oil is a viable option for stationary industrial boilers and furnaces designed to handle heavy fuel oils.

- If your primary focus is waste valorization: The true strength of pyrolysis lies in converting a waste stream into three valuable outputs: bio-oil, bio-char, and syngas.

- If your primary focus is advanced biofuel production: You should view raw pyrolysis oil as an intermediate product that requires significant upgrading and refining to create transportation-grade fuels.

Ultimately, pyrolysis offers a powerful method for converting low-value waste into energy and valuable materials, representing a key technology for a more circular and sustainable industrial future.

Summary Table:

| Application | Key Use | Key Consideration |

|---|---|---|

| Industrial Heating | Substitute for fuel oil in boilers and furnaces | Must meet standards like ASTM D7544 |

| Power Generation | Fuel for stationary electrical generators | Not suitable for standard engines without modification |

| Waste Valorization | Part of a system producing oil, biochar, and syngas | Quality and stability are current limitations |

Ready to integrate pyrolysis technology into your operations? KINTEK specializes in lab equipment and consumables for developing and testing pyrolysis processes. Whether you're exploring waste-to-energy solutions or need reliable equipment for your laboratory, our expertise can help you achieve efficient, sustainable results. Contact us today to discuss how we can support your specific laboratory needs!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

People Also Ask

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- How does precision temperature control impact TiAl alloy sintering? Master Microstructure Development

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What is the meaning of rotary furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding