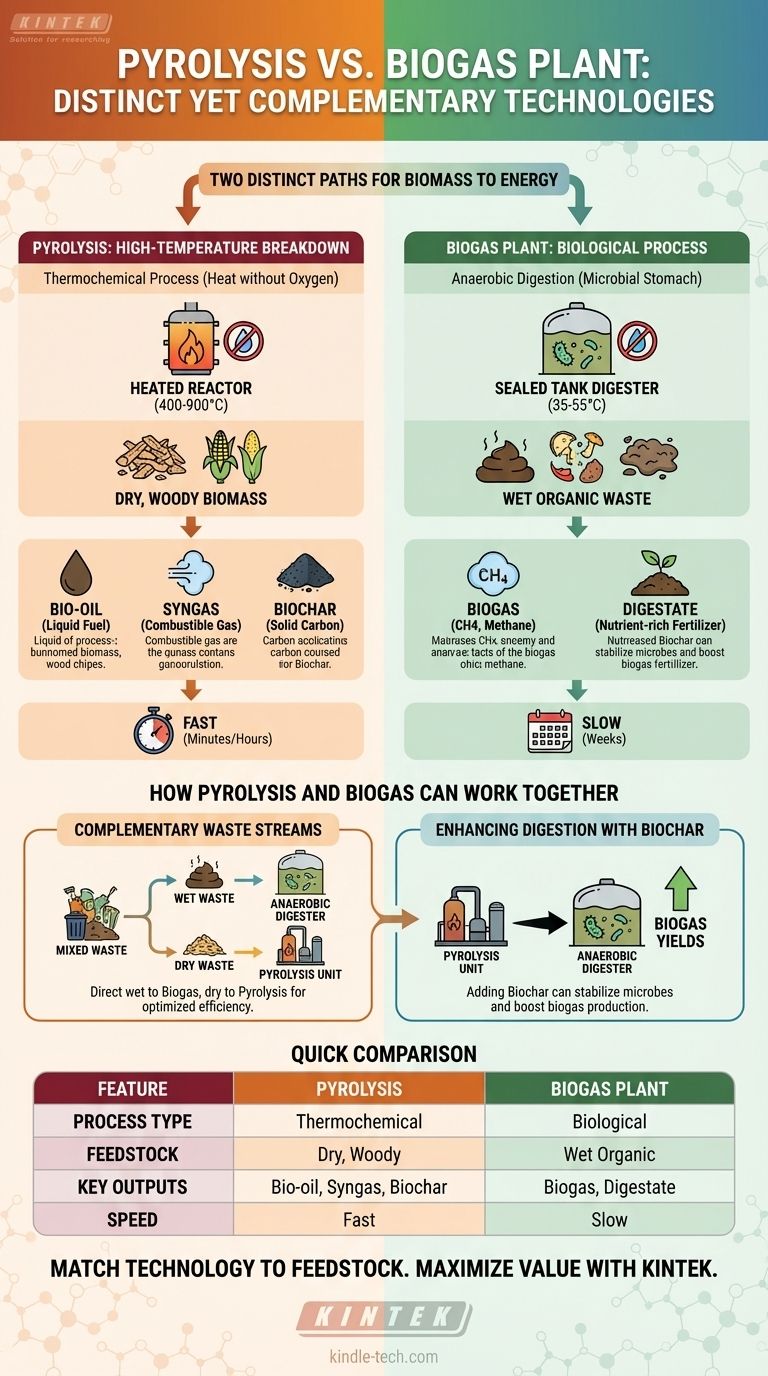

Critically, pyrolysis is not a standard process used in a biogas plant. Instead, they are two distinct technologies for converting biomass into energy. Pyrolysis is a high-temperature thermochemical process that breaks down material without oxygen, producing bio-oil, syngas, and biochar. A biogas plant, in contrast, uses a low-temperature biological process called anaerobic digestion to produce biogas.

While both technologies convert organic waste into energy, the fundamental difference is their method. Pyrolysis is a rapid, high-temperature thermal reaction, while biogas production is a slow, low-temperature biological fermentation. Understanding this distinction is key to choosing the right solution for a specific waste stream.

What is Pyrolysis? A High-Temperature Breakdown

The Core Principle: Heat Without Oxygen

Pyrolysis works by heating organic materials, such as wood chips, agricultural residue, or even plastics, to very high temperatures (400-900°C) inside a sealed reactor.

The crucial element is the absence of oxygen. This prevents the material from combusting and instead causes it to thermally decompose into different, more valuable components.

The Key Outputs: A Trio of Products

This decomposition process yields three primary products:

- Bio-oil: A liquid fuel, sometimes called pyrolysis oil, that can be used in boilers, furnaces, or upgraded into transportation fuels.

- Syngas: A mixture of combustible gases (primarily hydrogen and carbon monoxide) that can be burned to generate electricity or heat.

- Biochar: A stable, carbon-rich solid similar to charcoal. It is an excellent soil amendment and can be used for carbon sequestration.

Feedstocks for Pyrolysis

Pyrolysis is highly effective for dry, carbon-based materials. This includes agricultural waste like corn stalks and peanut shells, forest residues like wood chips and sawdust, and even industrial wastes like sewage sludge.

What is a Biogas Plant? A Biological Process

The Core Principle: Anaerobic Digestion

A biogas plant operates on a completely different principle. It uses a sealed tank called an anaerobic digester, which acts like a mechanical stomach.

Inside, microorganisms break down wet organic waste (like manure, food scraps, or wastewater sludge) in an oxygen-free environment. This biological process is much slower and occurs at much lower temperatures (typically 35-55°C).

The Key Outputs: Gas and Fertilizer

Anaerobic digestion produces two main outputs:

- Biogas: Primarily composed of methane (CH4), the main component of natural gas. It is a clean-burning fuel used for cooking, heating, and electricity generation.

- Digestate: A nutrient-rich liquid and solid byproduct that is an excellent organic fertilizer, returning valuable nutrients to the soil.

How Pyrolysis and Biogas Can Work Together

While they are separate processes, pyrolysis and anaerobic digestion can be used in a complementary fashion to maximize value from different waste streams.

Complementary Waste Streams

An integrated system might direct wet, easily digestible wastes like food scraps and manure to a biogas plant.

Simultaneously, dry, woody, and harder-to-digest biomass like wood waste or tough crop stalks (which are poor feedstocks for digestion) would be sent to a pyrolysis unit. This ensures each type of waste is processed by the most efficient technology.

Using Biochar to Enhance Digestion

A more direct integration involves using a byproduct of pyrolysis to improve the biogas process. Adding biochar to an anaerobic digester can increase the stability and efficiency of the microbial community, potentially leading to higher biogas yields.

Understanding the Trade-offs: Pyrolysis vs. Biogas

Feedstock Flexibility

Pyrolysis can handle a wider range of dry carbonaceous feedstocks, including some plastics and tires, which cannot be digested. Biogas plants excel at processing high-moisture organic waste that is unsuitable for pyrolysis.

Process Speed and Energy Input

Pyrolysis is a very fast process, converting biomass in minutes or hours. However, it requires a significant energy input to reach its high operating temperatures.

Anaerobic digestion is a much slower biological process that can take weeks, but it operates at low temperatures and has a lower energy requirement.

Output Products and Uses

Pyrolysis produces a storable liquid fuel (bio-oil) and a valuable solid (biochar). Biogas produces a gaseous fuel that must be used on-site or upgraded and compressed, along with a nutrient-rich fertilizer (digestate).

Making the Right Choice for Your Waste Stream

- If your primary feedstock is wet organic waste (manure, food scraps): A biogas plant offers the most direct and efficient technology for producing fuel and a valuable fertilizer.

- If your primary feedstock is dry, woody biomass (wood chips, crop residue): Pyrolysis provides a more effective route for conversion into a storable liquid fuel and valuable biochar.

- If you manage a mixed-waste stream: A hybrid approach, using both technologies for their ideal feedstocks, can maximize overall energy and value recovery.

By matching the technology to the specific characteristics of your feedstock, you can most effectively transform waste into a valuable resource.

Summary Table:

| Feature | Pyrolysis | Biogas Plant (Anaerobic Digestion) |

|---|---|---|

| Process Type | Thermochemical (Heat without oxygen) | Biological (Microbial digestion) |

| Primary Feedstock | Dry, woody biomass (e.g., wood chips, crop residue) | Wet organic waste (e.g., manure, food scraps) |

| Key Outputs | Bio-oil, Syngas, Biochar | Biogas (Methane), Digestate (Fertilizer) |

| Process Speed | Fast (minutes/hours) | Slow (weeks) |

Transform your biomass and waste streams into valuable energy and products with KINTEK.

Whether you are processing dry agricultural residue or wet organic waste, selecting the right technology is critical for maximizing efficiency and ROI. KINTEK specializes in advanced laboratory equipment and consumables for researching and optimizing both pyrolysis and anaerobic digestion processes.

Our experts can help you:

- Analyze your specific feedstock to determine the most effective conversion path.

- Source the precise lab-scale equipment needed for process development and testing.

- Scale your operations with reliable, high-performance solutions.

Ready to find the optimal solution for your biomass conversion needs? Contact our team today to discuss how KINTEK can support your laboratory and pilot-scale projects.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds