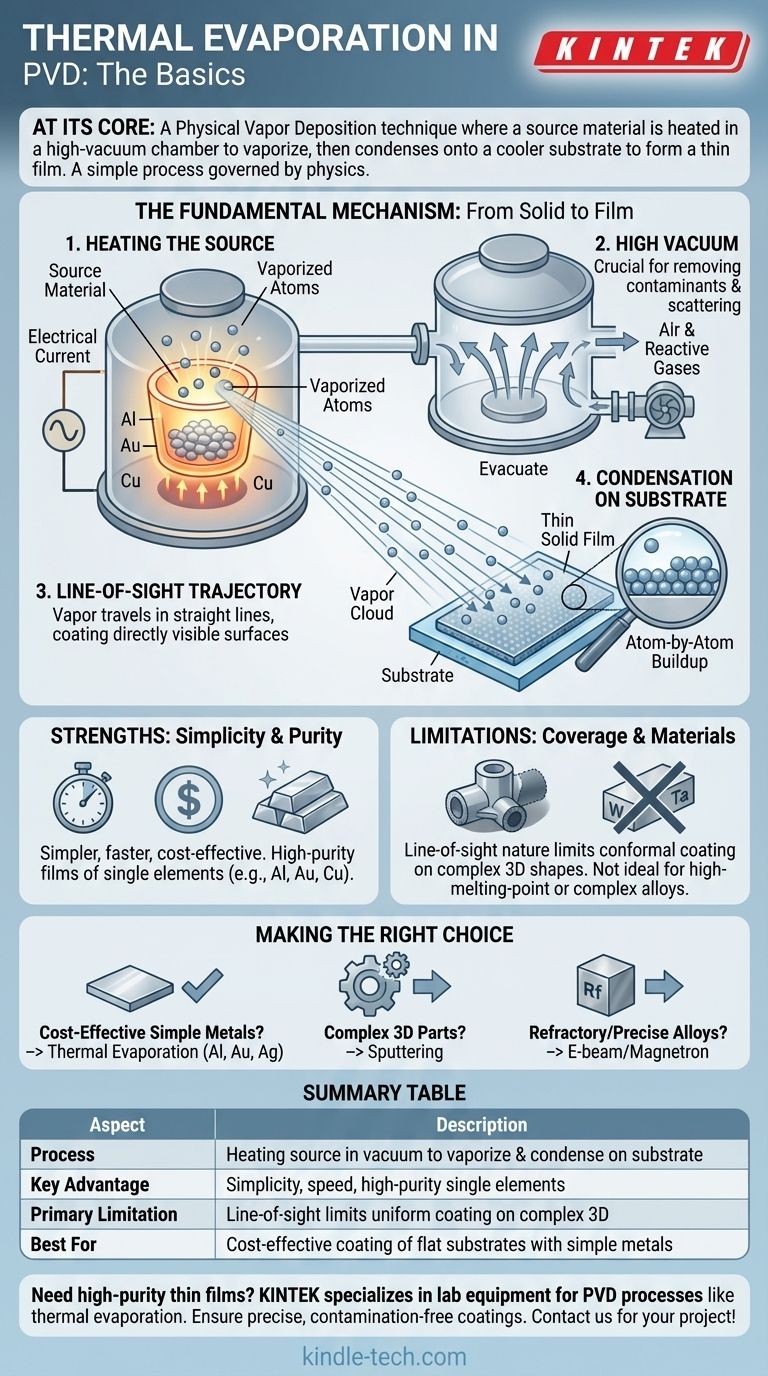

At its core, thermal evaporation is a Physical Vapor Deposition (PVD) technique used to create a thin film of material onto a surface. The process involves heating a source material inside a high-vacuum chamber until it vaporizes. These vaporized atoms then travel through the vacuum and condense onto a cooler target object, known as the substrate, forming a solid, uniform coating.

Thermal evaporation is a fundamentally straightforward process governed by physics: heating a material in a vacuum causes it to vaporize, and this vapor will condense on the first cool surface it encounters. The simplicity of this principle makes it a widely used technique, but its effectiveness depends entirely on controlling the relationship between heat, vacuum, and geometry.

The Fundamental Mechanism: From Solid to Film

To understand thermal evaporation, it's best to break it down into its four essential stages. Each stage is critical for achieving a high-quality thin film.

The Source Material and Heat

The process begins with the material you wish to deposit, known as the source material. This solid material, often in the form of pellets, wire, or powder, is placed into a heat-resistant crucible (like a small boat made of tungsten or ceramic).

An electrical current is then passed through the crucible or a nearby filament, causing it to heat up dramatically. This thermal energy is transferred to the source material, raising its temperature until it either melts and boils or sublimates (goes directly from a solid to a gas). This creates a cloud of vaporized atoms.

The Necessity of a Vacuum

This entire process is performed inside a high-vacuum chamber. The vacuum is not a minor detail; it is absolutely crucial for two reasons.

First, it removes air molecules that would otherwise collide with the vaporized source atoms, scattering them and preventing them from reaching the substrate. Second, it eliminates reactive gases like oxygen and water vapor, which could contaminate the source material and the final film, leading to poor quality and adhesion.

Line-of-Sight Deposition

Once vaporized in the vacuum, the atoms travel in straight lines away from the source. This is referred to as a line-of-sight trajectory.

The vapor cloud expands and coats everything it can "see" directly from the source's vantage point.

Condensation on the Substrate

The final step occurs when the vaporized atoms strike the substrate—the object being coated. Because the substrate is kept at a significantly lower temperature than the source, the atoms rapidly lose their thermal energy upon impact.

This energy loss causes them to condense back into a solid state, adhering to the surface and gradually building up, atom by atom, to form a thin, solid film.

Understanding the Trade-offs

Like any technical process, thermal evaporation has distinct advantages and limitations that make it suitable for some applications but not others.

Strength: Simplicity and Purity

Thermal evaporation is generally simpler, faster, and more cost-effective than other PVD methods like sputtering. The equipment can be less complex, and it's an excellent method for depositing high-purity films of many single elements, particularly metals with lower melting points like aluminum, gold, copper, and chromium.

Limitation: Line-of-Sight Coverage

The line-of-sight nature of the process is its primary drawback. It cannot uniformly coat complex, three-dimensional shapes with undercuts or hidden surfaces. Areas not directly in the path of the vapor will receive little to no coating, resulting in a non-uniform film.

Limitation: Material Constraints

This technique is not ideal for all materials. High-melting-point materials (like tungsten or tantalum) require specialized and more energetic heating methods (like electron-beam evaporation). Furthermore, depositing complex alloys is difficult because the individual elements in the alloy will often evaporate at different rates, changing the composition of the final film.

Making the Right Choice for Your Goal

Selecting the right deposition method requires aligning the process capabilities with your desired outcome.

- If your primary focus is cost-effective deposition of simple metals: Thermal evaporation is an excellent, straightforward choice for applying films like aluminum, gold, or silver onto relatively flat substrates.

- If your primary focus is coating complex 3D parts uniformly: You should consider alternative PVD methods like sputtering, which does not rely on line-of-sight and provides much better conformal coverage.

- If your primary focus is depositing refractory metals or precise alloys: Look to more energetic processes like electron-beam evaporation or magnetron sputtering, which offer the control needed to handle these challenging materials.

By understanding its core principles and inherent limitations, you can effectively leverage thermal evaporation as a powerful tool for creating high-quality thin films.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Heating a source material in a high-vacuum chamber until it vaporizes, then condensing it onto a substrate. |

| Key Advantage | Simplicity, speed, and ability to deposit high-purity films of single elements (e.g., Al, Au, Cu). |

| Primary Limitation | Line-of-sight deposition limits uniform coating on complex 3D shapes. |

| Best For | Cost-effective coating of relatively flat substrates with simple metals. |

Need high-purity thin films for your lab? KINTEK specializes in lab equipment and consumables for PVD processes like thermal evaporation. Whether you're depositing metals for research or production, our expertise ensures you get the right solution for precise, contamination-free coatings. Contact us today to discuss your project and enhance your laboratory's capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process