At its core, thermal evaporation is a physical vapor deposition (PVD) process used to create extremely thin films of material. The technique involves heating a source material, such as a pure metal, inside a high-vacuum chamber until it evaporates. This vapor then travels and condenses onto a cooler surface, called a substrate, forming a solid, ultra-thin film.

While thermal evaporation is one of the simplest and most direct methods for creating thin films, its success is not automatic. The quality and uniformity of the final layer depend critically on precise control over the vacuum environment, heating rate, and substrate conditions.

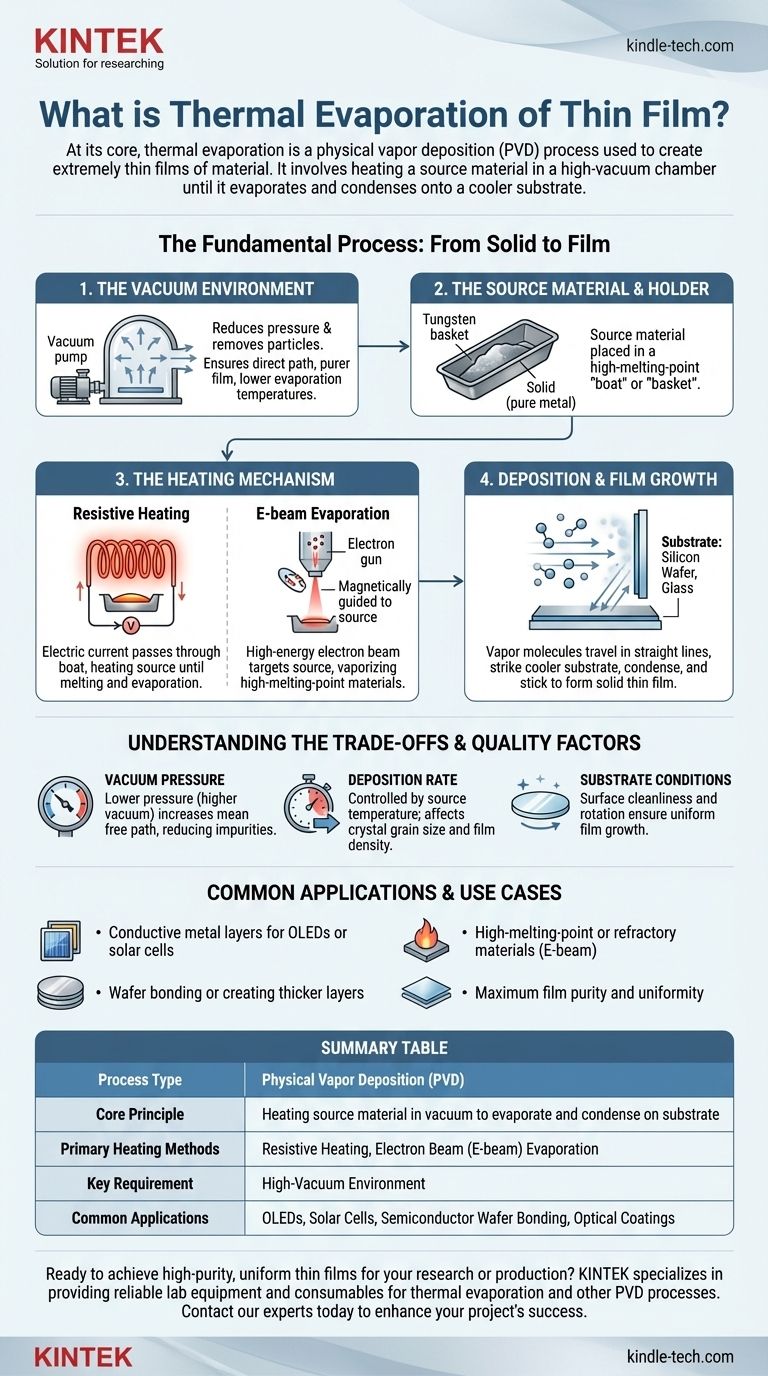

The Fundamental Process: From Solid to Film

To understand thermal evaporation, it's best to break it down into its core components and stages. The entire process occurs within a sealed chamber under high vacuum.

The Vacuum Environment

A high vacuum is the most critical element. It serves two purposes: it reduces the pressure so materials can evaporate at lower temperatures, and it removes air and other particles. This ensures the evaporated material can travel directly to the substrate without colliding with other molecules, preventing contamination and ensuring a purer film.

The Source Material and Holder

The material to be deposited, often called the source, is placed in a container. This holder is typically referred to as a "boat" or "basket" and is made from a material with a very high melting point, such as tungsten.

The Heating Mechanism

The source material is heated until it turns into a gas (vapor). This is accomplished in one of two primary ways, which defines the specific type of thermal evaporation being used.

Deposition and Film Growth

Once vaporized, molecules from the source material travel in a straight line through the vacuum. When they strike the cooler substrate (such as a silicon wafer, glass, or plastic), they rapidly cool, condense, and stick to the surface, building up layer by layer to form a solid thin film.

Key Types of Thermal Evaporation

While the principle is the same, the method of heating the source material creates an important distinction.

Resistive Heating

This is the most common and straightforward form of thermal evaporation. An electric current is passed through the resistive boat or coil holding the source material. The boat heats up, transferring that thermal energy to the source, causing it to melt and then evaporate.

Electron Beam (E-beam) Evaporation

For materials with very high melting points, resistive heating may not be sufficient. In E-beam evaporation, a high-energy beam of electrons is fired from an "electron gun" and magnetically guided to strike the source material. The intense, focused energy causes localized heating and evaporation.

Understanding the Trade-offs and Quality Factors

The simplicity of thermal evaporation is its greatest strength, but several factors can dramatically affect the outcome. Achieving a high-quality film requires careful management of the process variables.

The Critical Role of Vacuum Pressure

A lower pressure (a higher vacuum) is almost always better. It increases the mean free path—the average distance a vapor molecule can travel before hitting something else. This leads to a more direct path to the substrate and fewer impurities in the final film.

The Impact of Deposition Rate

The rate at which the source material evaporates influences the structure of the film. This rate is controlled by the temperature of the source. Different rates can affect crystal grain size and film density.

Substrate Conditions and Uniformity

The condition of the substrate is paramount. A rough or unclean surface can lead to non-uniform film growth. To ensure an even coating across a larger area, substrates are often rotated during the deposition process.

Common Applications and Use Cases

Thermal evaporation is a foundational technique in manufacturing advanced electronics and materials. Its applications are widespread and are chosen based on the need for specific material layers.

- If your primary focus is creating conductive metal layers for OLEDs or solar cells: Thermal evaporation is a standard, cost-effective method for depositing the thin metallic contacts these devices require.

- If your primary focus is depositing high-melting-point or refractory materials: E-beam evaporation is the superior choice, as its focused energy can vaporize materials that are impossible to heat with a resistive boat.

- If your primary focus is wafer bonding or creating thicker layers: This technique is well-suited for depositing thicker layers of materials like indium, which are used to bond semiconductor wafers together.

- If your primary focus is ensuring maximum film purity and uniformity: You must prioritize a high-vacuum system, a clean substrate, and a mechanism for substrate rotation during deposition.

Ultimately, mastering thermal evaporation is a matter of understanding and precisely controlling these fundamental physical principles to build materials one atomic layer at a time.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Principle | Heating a source material in a vacuum until it evaporates and condenses on a substrate. |

| Primary Heating Methods | Resistive Heating, Electron Beam (E-beam) Evaporation |

| Key Requirement | High-Vacuum Environment |

| Common Applications | OLEDs, Solar Cells, Semiconductor Wafer Bonding, Optical Coatings |

Ready to achieve high-purity, uniform thin films for your research or production? KINTEK specializes in providing reliable lab equipment and consumables for thermal evaporation and other PVD processes. Our expertise ensures you get the right solutions for depositing conductive metals, high-melting-point materials, and more. Contact our experts today to discuss how we can support your laboratory's thin film deposition needs and enhance your project's success.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods