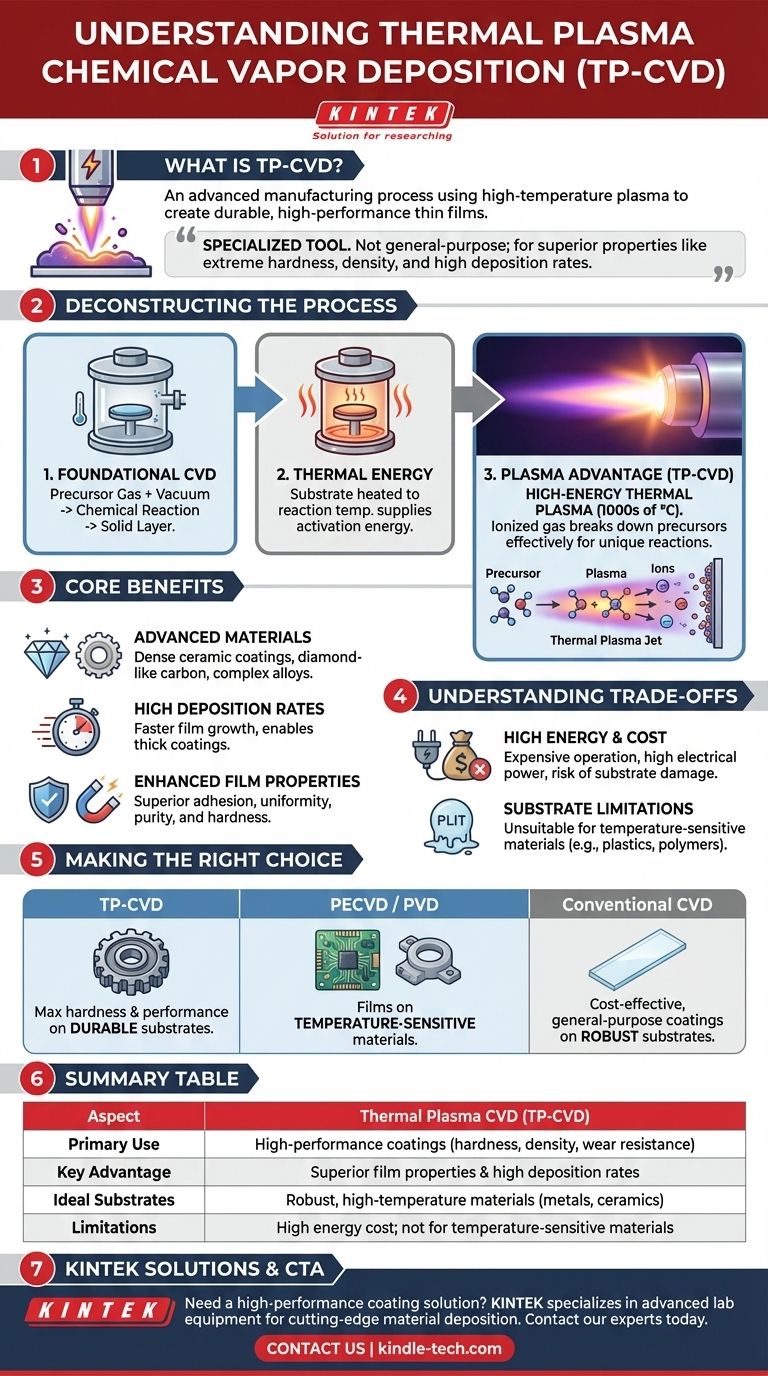

In essence, Thermal Plasma Chemical Vapor Deposition (TP-CVD) is an advanced manufacturing process that uses a high-temperature, electrically charged gas (a plasma) to deposit exceptionally durable and high-performance thin films onto a surface. It builds on the principles of standard Chemical Vapor Deposition (CVD) but leverages the intense energy of a thermal plasma to break down precursor chemicals more effectively, enabling the creation of materials that are otherwise difficult to produce.

The critical takeaway is that Thermal Plasma CVD is not a general-purpose tool; it is a specialized, high-energy process used when the primary goal is to create coatings with superior properties like extreme hardness, density, or unique chemical compositions, often at very high deposition rates.

Deconstructing the Process: How It Works

To understand Thermal Plasma CVD, we must first understand its three core components: the foundational CVD process, the role of thermal energy, and the critical addition of a high-temperature plasma.

The Foundation: Chemical Vapor Deposition (CVD)

At its core, any CVD process involves placing a component or substrate inside a reaction chamber.

A volatile precursor chemical, usually in gaseous form, is then introduced into the chamber, which is often under a vacuum.

This gas undergoes a chemical reaction at or near the substrate's surface, breaking down and depositing a solid material layer by layer, forming a thin, even film.

The "Thermal" Component: Supplying the Energy

For the precursor gas to react and deposit a film, it needs an input of energy.

In standard thermal CVD, this energy is supplied simply by heating the substrate to a specific reaction temperature. This heat gives the gas molecules the energy they need to break apart and bond to the surface.

The "Plasma" Advantage: Creating a High-Energy State

Thermal Plasma CVD introduces a powerful third element: a plasma. A plasma is an ionized gas—a state of matter where atoms are broken into electrons and positive ions, creating a highly energetic and reactive environment.

A thermal plasma is particularly intense, characterized by extremely high temperatures (thousands of degrees Celsius) where all particles are in thermal equilibrium.

This jet of intense energy is far more effective at breaking down precursor gases than heat alone, allowing for reactions that wouldn't otherwise be possible.

Why Use Thermal Plasma? The Core Benefits

Adding a thermal plasma to the CVD process is complex and energy-intensive, but it provides distinct advantages for specific applications.

Depositing Advanced and Unique Materials

The immense energy of the plasma can create highly durable materials like dense ceramic coatings, diamond-like carbon, or complex alloys.

These materials are often used for applications demanding extreme wear resistance and corrosion protection, such as on industrial cutting tools or aerospace components.

Achieving High Deposition Rates

Because the plasma accelerates the chemical reactions so dramatically, films can be grown much faster than with conventional CVD methods. This makes the process viable for applications requiring thick coatings.

Enhancing Film Properties

The resulting films often exhibit superior qualities. The high energy of the process typically leads to denser, more uniform, and purer coatings with stronger adhesion to the substrate.

Understanding the Trade-offs

While powerful, Thermal Plasma CVD is not a universally applicable solution. Its high-energy nature brings significant limitations.

High Temperatures and Energy Costs

Generating and sustaining a thermal plasma requires a tremendous amount of electrical power, making the process expensive to operate.

The extreme temperatures involved can easily damage the material being coated if it is not sufficiently robust.

Substrate Limitations

This process is generally unsuitable for temperature-sensitive substrates like plastics, polymers, or many common semiconductor materials. The intense heat would simply destroy them.

Equipment and Process Complexity

Controlling a thermal plasma jet requires highly sophisticated and expensive equipment. Managing the interplay between gas flow, pressure, and power to achieve a stable and uniform coating is a significant engineering challenge.

Making the Right Choice for Your Goal

Selecting the right deposition technology depends entirely on the material requirements and the substrate being used.

- If your primary focus is maximum hardness and performance on a durable substrate: TP-CVD is an excellent candidate for creating superior wear-resistant or protective coatings.

- If your primary focus is depositing a film on a temperature-sensitive material: TP-CVD is entirely unsuitable; you should consider lower-temperature processes like standard Plasma-Enhanced CVD (PECVD) or Physical Vapor Deposition (PVD).

- If your primary focus is cost-effective, general-purpose coatings on robust substrates: Conventional thermal CVD may provide the necessary quality without the complexity and expense of a plasma system.

Ultimately, Thermal Plasma CVD is a powerful but highly specialized tool for engineering materials at the atomic level to meet the most demanding performance requirements.

Summary Table:

| Aspect | Thermal Plasma CVD (TP-CVD) |

|---|---|

| Primary Use | High-performance coatings (hardness, density, wear resistance) |

| Key Advantage | Superior film properties & high deposition rates |

| Ideal Substrates | Robust, high-temperature materials (e.g., metals, ceramics) |

| Limitations | High energy cost; not for temperature-sensitive materials |

Need a high-performance coating solution for your toughest industrial challenges?

Thermal Plasma CVD is a specialized process for creating ultra-durable, high-purity coatings that stand up to extreme conditions. At KINTEK, we specialize in advanced lab equipment and consumables, providing the precise thermal and plasma systems needed for cutting-edge material deposition.

Our expertise helps you achieve:

- Exceptional Coating Hardness & Density for maximum wear and corrosion resistance.

- High Deposition Rates to efficiently build thick, uniform films.

- Solutions for Robust Substrates used in aerospace, tooling, and industrial manufacturing.

Let's engineer the perfect coating solution for your specific material and performance goals. Contact our experts today to discuss how KINTEK can enhance your R&D or production process.

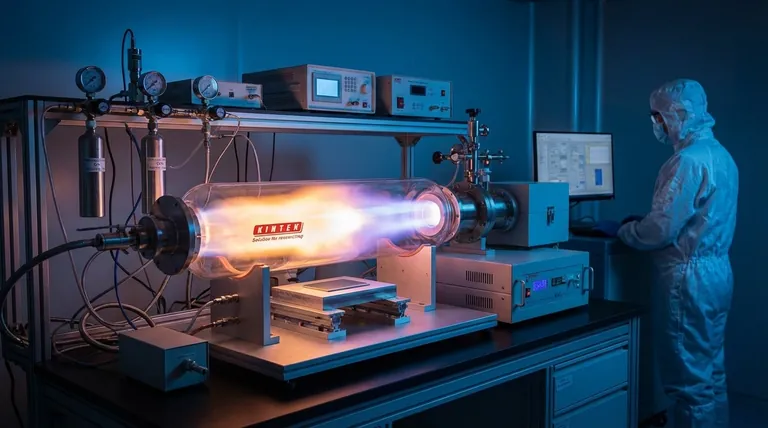

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings