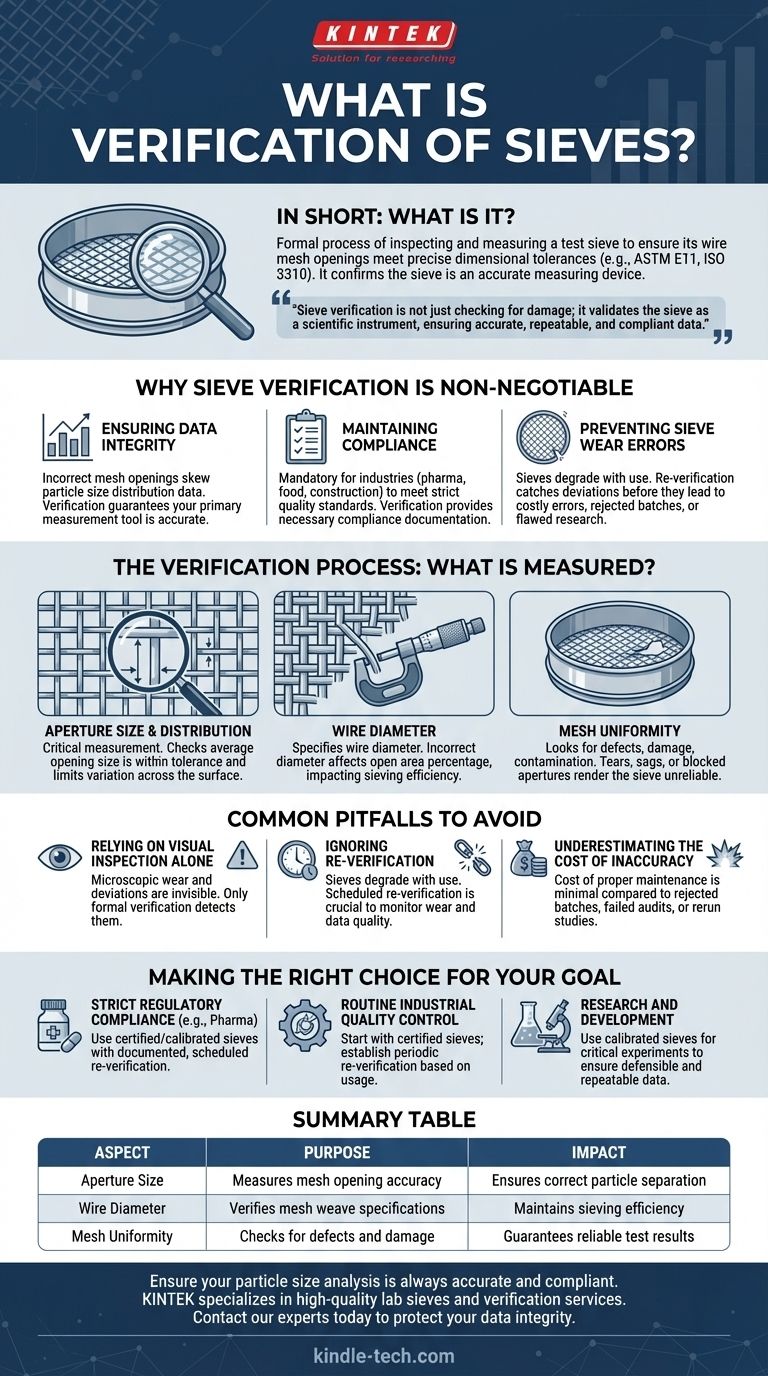

In short, sieve verification is the formal process of inspecting and measuring a test sieve to ensure its wire mesh openings meet the precise dimensional tolerances required by standards like ASTM E11 or ISO 3310. It confirms that the sieve is an accurate measuring device, suitable for reliable particle size analysis. This applies to both brand-new sieves and used sieves as part of an ongoing quality control program.

Sieve verification is not just about checking for damage; it is a critical quality assurance step that validates the sieve as a scientific instrument, ensuring that the data you collect is accurate, repeatable, and compliant with industry standards.

Why Sieve Verification is Non-Negotiable

A test sieve might look like a simple piece of wire mesh, but in a technical setting, it's a precision measurement tool. Its performance directly impacts the integrity of your results.

Ensuring Data Integrity

The fundamental purpose of a sieve is to separate particles by size. If the openings in the mesh (the apertures) are incorrect—even by a few micrometers—your entire particle size distribution data will be skewed. Verification guarantees that your primary measurement tool is accurate.

Maintaining Compliance

Many industries, especially pharmaceuticals, food, and construction materials, must adhere to strict quality standards. These standards often mandate that the test sieves used for quality control are compliant with specifications like ASTM E11. Verification provides the necessary documentation to prove this compliance.

Preventing Sieve Wear from Causing Errors

Sieves are not immune to wear and tear. Over time, abrasive materials can stretch the mesh, and improper handling can cause damage. A process of re-verification checks the performance of used sieves to catch these deviations before they lead to costly errors like rejected product batches or flawed research conclusions.

The Verification Process: What is Actually Measured?

Verification goes far beyond a simple visual check. It involves using sophisticated optical equipment to measure key aspects of the sieve mesh against its required specification.

Aperture Size and Distribution

This is the most critical measurement. The process checks that the average size of the mesh openings is within the specified tolerance. It also ensures that there isn't excessive variation in opening sizes across the sieve surface.

Wire Diameter

The standard also specifies the diameter of the wire used to weave the mesh. Incorrect wire diameter affects the percentage of open area on the sieve, which can impact sieving efficiency and the accuracy of the results.

Mesh Uniformity

The inspection looks for manufacturing defects, damage, or contamination. Any tears, sags in the mesh, or blocked apertures would render the sieve non-compliant and unreliable for testing.

Common Pitfalls to Avoid

Understanding the limitations and common mistakes associated with sieve use is crucial for maintaining a high-quality process.

Mistake 1: Relying on Visual Inspection Alone

A common error is assuming a sieve is "good enough" if it looks clean and undamaged to the naked eye. Microscopic wear, stretching of the wires, or slight deviations in aperture size are invisible but can significantly impact results. Only a formal verification process can detect them.

Mistake 2: Ignoring Re-verification

Purchasing a certified new sieve is a great start, but it's not the end of the story. Sieves degrade with use. Without a scheduled re-verification program, you have no way of knowing when a sieve has worn out of its specification, putting your data quality at risk.

Mistake 3: Underestimating the Cost of Inaccuracy

The cost of verifying a sieve is minimal compared to the potential cost of using a non-compliant one. A single rejected product batch, a failed regulatory audit, or the need to rerun an entire research study due to bad data will far outweigh the expense of proper equipment maintenance.

Making the Right Choice for Your Goal

Your approach to sieve verification should align with your operational needs and quality standards.

- If your primary focus is strict regulatory compliance (e.g., pharmaceuticals): You must use certified or calibrated sieves and implement a documented, scheduled re-verification program.

- If your primary focus is routine industrial quality control: Start with certified sieves and establish a periodic re-verification schedule based on usage frequency and the abrasiveness of your material.

- If your primary focus is research and development: Using calibrated sieves for critical experiments is essential to ensure your data is defensible and repeatable.

Ultimately, a consistent verification program elevates a simple sieve from a tool to a trusted instrument for measurement.

Summary Table:

| Aspect | Purpose | Impact |

|---|---|---|

| Aperture Size | Measures mesh opening accuracy | Ensures correct particle separation |

| Wire Diameter | Verifies mesh weave specifications | Maintains sieving efficiency |

| Mesh Uniformity | Checks for defects and damage | Guarantees reliable test results |

Ensure your particle size analysis is always accurate and compliant. KINTEK specializes in high-quality lab sieves and verification services. Our certified sieves and recalibration programs help laboratories in pharmaceuticals, construction, and food industries maintain strict quality standards. Contact our experts today to discuss your sieve verification needs and protect the integrity of your data.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy