The most common materials for dental crowns are ceramic (including porcelain), porcelain-fused-to-metal, and all-metal alloys. Other materials like stainless steel and all-resin are typically used for more temporary or specific applications, such as on children's primary teeth. The final choice depends on the tooth's location in your mouth, aesthetics, durability requirements, and budget.

While several materials are available, the fundamental decision often balances the superior, natural appearance of all-ceramic crowns with the brute-force durability of metal. Modern ceramics aim to bridge this gap, offering both strength and beauty.

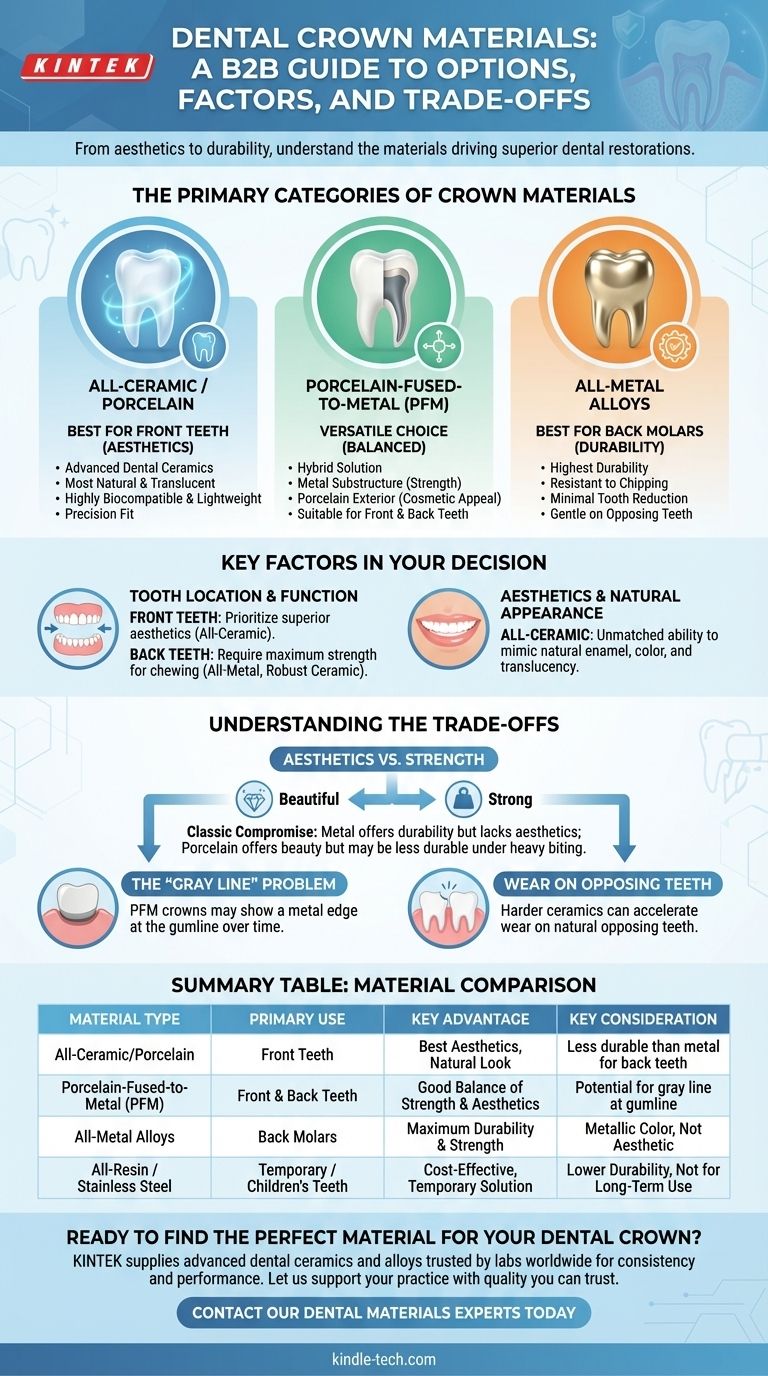

The Primary Categories of Crown Materials

Understanding the core options is the first step. Each material category serves a different primary purpose, from perfectly mimicking a natural tooth to providing maximum chewing strength.

All-Ceramic and All-Porcelain

These crowns are crafted from advanced dental ceramics, such as leucite-based or lithium disilicate-based materials, prized for their quality and longevity.

Porcelain is a specific type of ceramic that offers the most natural and translucent appearance, making it the premier choice for front teeth where aesthetics are paramount.

They are lightweight, biocompatible, and can be shaped with high precision to ensure a comfortable fit.

Porcelain-Fused-to-Metal (PFM)

This is a hybrid solution that combines the strength of a metal substructure with the cosmetic appeal of a porcelain exterior.

The underlying metal shell provides excellent durability, making PFM crowns strong enough for both front and back teeth. The porcelain is then bonded over this shell to match the color of your surrounding teeth.

All-Metal Alloys

All-metal crowns offer the highest durability and are the most resistant to chipping or breaking. They are typically made from gold alloys or other base-metal alloys.

Because of their metallic color, they are almost exclusively used for out-of-sight molars. They require less removal of the natural tooth structure than other crown types.

Key Factors in Your Decision

The "best" material is not a universal answer; it depends entirely on your specific clinical situation and personal priorities.

Tooth Location and Function

The location is the most significant factor. Front teeth are highly visible and require the superior aesthetics of an all-ceramic or porcelain crown.

Back teeth (molars) endure immense chewing forces and benefit from the superior strength of all-metal or robust ceramic crowns.

Aesthetics and Natural Appearance

If your primary goal is a crown that is indistinguishable from your natural teeth, all-ceramic is the clear winner. The material's ability to mimic the color, shine, and translucency of tooth enamel is unmatched.

Durability and Longevity

For pure, long-term strength, all-metal crowns are the gold standard. They wear down slowly and are exceptionally gentle on the opposing teeth they bite against. Modern ceramics have become incredibly strong, but they can be more abrasive to natural teeth.

Understanding the Trade-offs

Every material choice involves compromises. Being aware of these helps you set realistic expectations for your dental restoration.

Aesthetics vs. Strength

This is the classic trade-off. While an all-metal crown on a molar is incredibly durable, you sacrifice aesthetics. An all-porcelain crown on that same molar might look better but could be more susceptible to fracture under heavy biting forces.

The "Gray Line" Problem

Porcelain-fused-to-metal (PFM) crowns can sometimes show a dark or gray line at the gumline over time. This is the underlying metal edge becoming visible if your gums recede.

Wear on Opposing Teeth

Harder materials, particularly some types of porcelain, can cause accelerated wear on the natural teeth they bite against. This is a crucial consideration your dentist will evaluate to protect your overall bite.

Making the Right Choice for Your Goal

Consulting with your dentist is essential, but you can go into that conversation prepared by knowing your priorities.

- If your primary focus is aesthetics for a visible front tooth: An all-ceramic or all-porcelain crown is your best option for a seamless, natural look.

- If your primary focus is maximum durability for a back molar: An all-metal crown provides exceptional strength and longevity for heavy chewing.

- If your primary focus is a balance of good aesthetics and high strength: A porcelain-fused-to-metal (PFM) or a modern high-strength ceramic (like zirconia) crown is a reliable, versatile choice.

Ultimately, the goal is to choose a material that restores the tooth's function, looks natural, and provides lasting value for your specific needs.

Summary Table:

| Material Type | Primary Use | Key Advantage | Key Consideration |

|---|---|---|---|

| All-Ceramic/Porcelain | Front Teeth | Best Aesthetics, Natural Look | Less durable than metal for back teeth |

| Porcelain-Fused-to-Metal (PFM) | Front & Back Teeth | Good Balance of Strength & Aesthetics | Potential for gray line at gumline |

| All-Metal Alloys | Back Molars | Maximum Durability & Strength | Metallic Color, Not Aesthetic |

| All-Resin / Stainless Steel | Temporary / Children's Teeth | Cost-Effective, Temporary Solution | Lower Durability, Not for Long-Term Use |

Ready to Find the Perfect Material for Your Dental Crown?

Choosing the right crown material is crucial for the long-term health and appearance of your smile. At KINTEK, we understand that dental professionals need reliable, high-quality materials to provide the best patient outcomes.

We supply advanced dental ceramics and alloys trusted by labs worldwide for their consistency and performance. Whether you're crafting a highly aesthetic all-ceramic crown for a front tooth or a durable metal crown for a molar, KINTEK provides the materials you can depend on.

Let us support your practice with quality you can trust.

Contact our dental materials experts today to discuss your specific needs and learn how we can help you achieve superior results for your patients.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the factors affecting ceramic structure? From Atomic Charge to Final Properties

- What is the purpose of using ceramic fiber insulation in molten salt pipelines? Ensure Fluidity and Energy Efficiency

- What is ceramic powder used for? Unlocking High-Performance Materials for Your Industry

- What determines the strength of ceramics? The surprising role of microscopic flaws in brittle failure

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance

- What are the advantages of dental ceramics? Achieve a Natural, Durable Smile

- What are the advantages of microwave sintering? Faster, More Efficient, and Superior Material Properties

- What are the different types of ceramic styles? A Guide to Earthenware, Stoneware, Porcelain & Bone China