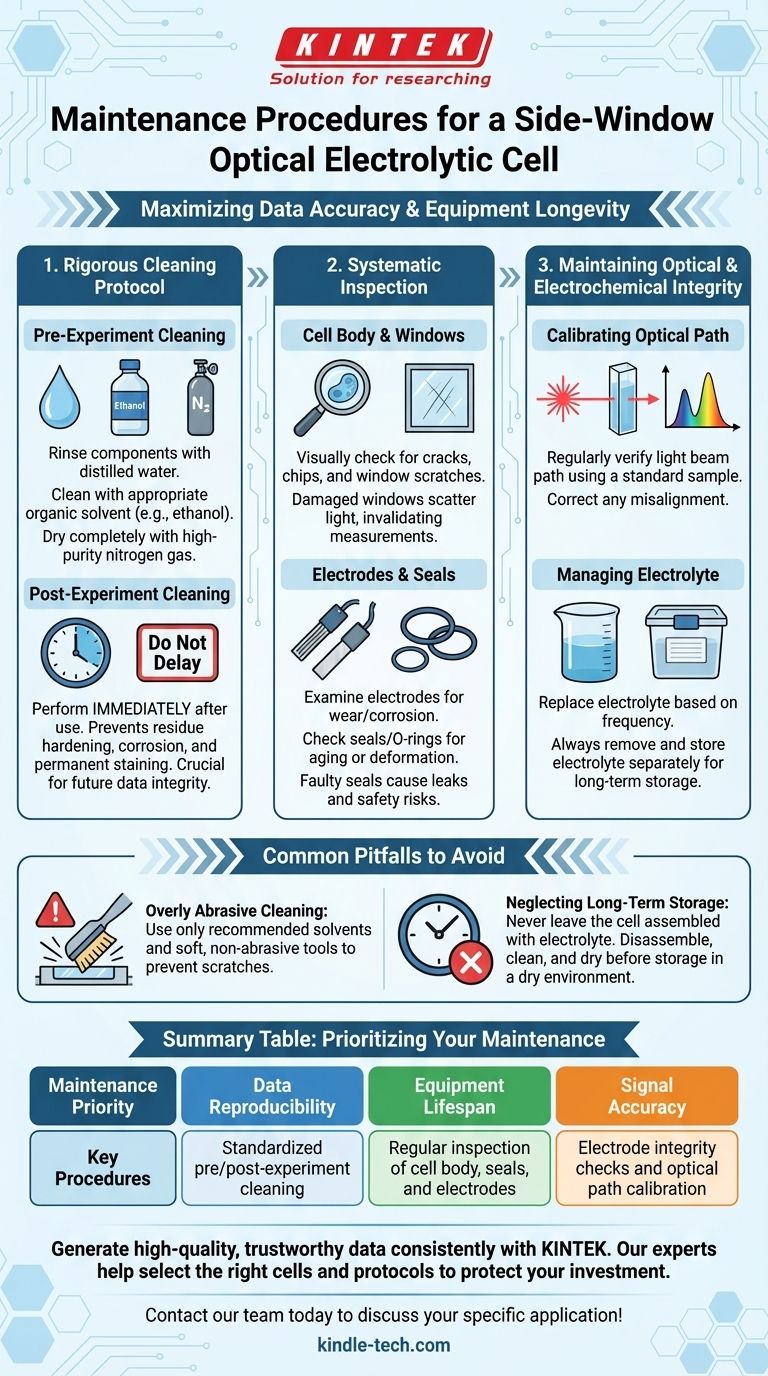

Proper maintenance of a side-window optical electrolytic cell centers on three core activities: a rigorous cleaning protocol before and after each use, systematic inspection of all components for wear and damage, and careful management of the optical and electrochemical systems. These procedures are not just for upkeep; they are fundamental to ensuring the accuracy and reproducibility of your experimental data.

The quality of your spectroelectrochemical data is a direct reflection of your cell's condition. Viewing maintenance not as a separate chore but as an integral part of the experimental protocol is the key to preventing data artifacts, extending equipment life, and achieving reliable results.

The Foundation: A Rigorous Cleaning Protocol

A pristine cell is the starting point for any valid experiment. Contaminants, whether from previous experiments or the environment, can introduce significant errors.

Pre-Experiment Cleaning

Before assembling the cell, perform a multi-step cleaning process to establish a clean baseline. First, rinse all components thoroughly with distilled or deionized water.

Next, soak and clean the cell with an appropriate organic solvent, such as ethanol, to remove organic residues. Finally, dry the components completely with a stream of high-purity nitrogen gas to avoid reintroducing moisture or contaminants.

Post-Experiment Cleaning

Cleaning must be performed immediately after each experiment. This prevents reaction byproducts and electrolyte salts from drying and hardening onto the cell body, windows, and electrodes.

Letting residues sit can lead to corrosion, permanent staining of the optical windows, and contamination that is difficult to remove later, compromising future experiments.

Systematic Inspection: The Key to Longevity

Regular physical inspection allows you to catch minor issues before they lead to catastrophic failure or skewed data.

The Cell Body and Windows

Visually inspect the cell body for any cracks or chips, particularly around the electrode ports and seals. Even a hairline crack can compromise the system's integrity.

Examine the optical windows for cleanliness, scratches, and transparency. Minor scratches on the cell body can sometimes be treated with a polishing agent, but any damage to the optical window surface will scatter light and invalidate optical measurements.

The Electrodes

Electrodes are consumable components. Check the working, counter, and reference electrodes for signs of physical wear, corrosion, or pitting. Degraded electrodes can lead to increased resistance and unstable signals.

When installing, ensure the electrodes are seated correctly and make good contact with their interfaces. A poor connection is a common source of unreliable electrochemical data.

Seals and Interfaces

Inspect all seals and O-rings for signs of aging, such as brittleness or deformation. A faulty seal is the primary cause of electrolyte leakage.

Leaking electrolyte not only compromises the experiment's controlled environment but also poses a safety risk to the operator and can damage the surrounding instrumentation.

Maintaining Optical and Electrochemical Integrity

Beyond physical cleanliness, you must ensure the cell is performing its specific functions correctly.

Calibrating the Optical Path

For a spectroelectrochemical cell, the optical path is critical. You must regularly verify that the light beam passes accurately through the sample in the cell.

This can be confirmed by measuring the optical signal of a standard sample with a known absorbance. Any deviation suggests a misalignment that needs to be corrected.

Managing the Electrolyte

The electrolyte should be replaced based on usage frequency. Over time, it can accumulate impurities from the electrodes or atmospheric exposure, which will influence the reaction and its optical properties.

For long-term storage, always remove the electrolyte from the cell. Store the electrolyte in a separate, sealed container if it is to be reused.

Common Pitfalls to Avoid

Even with the best intentions, improper maintenance can cause more harm than good.

Overly Abrasive Cleaning

While cleaning is critical, using harsh abrasives or incompatible cleaning agents can permanently scratch the optical windows or damage the cell material. Always use recommended solvents and soft, non-abrasive tools.

Neglecting Long-Term Storage

Leaving a cell assembled with electrolyte in it for extended periods is a common mistake. This can lead to severe corrosion of the electrodes and electrode mounts, and can cause the electrolyte to "creep" and damage seals.

Always disassemble, clean, and dry the cell before storing it. Store all components in a clean, dry, and non-humid environment to prevent degradation.

Making the Right Choice for Your Goal

Integrate these procedures into your standard experimental workflow based on your top priority.

- If your primary focus is data reproducibility: Your most critical step is a standardized pre- and post-experiment cleaning protocol used by everyone in the lab.

- If your primary focus is long-term equipment lifespan: Prioritize regular, documented inspections of the cell body, seals, and electrodes to catch and address wear early.

- If your primary focus is signal accuracy: Concentrate on maintaining electrode integrity and performing routine optical path calibrations to ensure your measurements are valid.

Consistent and methodical maintenance is your best insurance policy for generating high-quality, trustworthy data.

Summary Table:

| Maintenance Priority | Key Procedures |

|---|---|

| Data Reproducibility | Standardized pre/post-experiment cleaning |

| Equipment Lifespan | Regular inspection of cell body, seals, and electrodes |

| Signal Accuracy | Electrode integrity checks and optical path calibration |

Generate high-quality, trustworthy data consistently. Proper maintenance is key to the performance of your spectroelectrochemical equipment. KINTEK specializes in premium lab equipment and consumables, serving the precise needs of research laboratories. Our experts can help you select the right cells and establish best-practice protocols to protect your investment and ensure experimental success.

Contact our team today to discuss your specific application and maintenance needs!

Visual Guide

Related Products

- Side Window Optical Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- What are the advantages of electrodeposition for GQDs on TiO2? Enhance Adhesion and Precision in Your Research

- Why is an electrochemical workstation required for EQCMD? Unlock Conductivity and Crystallization Insights

- Why is a 3-electrode cell used for EIS testing of magnesium coatings? Ensuring Precise Electrochemical Data

- What is the role of an Anion Exchange Membrane (AEM)? Boost Safety and Efficiency in Photoelectrochemical Systems

- What are the key safety precautions for operating a super-sealed electrolytic cell? Essential Protocols for Laboratory Safety

- What are the steps for post-experiment procedures after using the cell with a conventional aqueous solution? Ensure Accuracy and Reproducibility

- How should the products and waste from the electrolytic cell be handled after an experiment? A Safety and Maintenance Guide

- What experimental conditions does a three-electrode electrolytic cell provide? Optimize Precise Corrosion Analysis