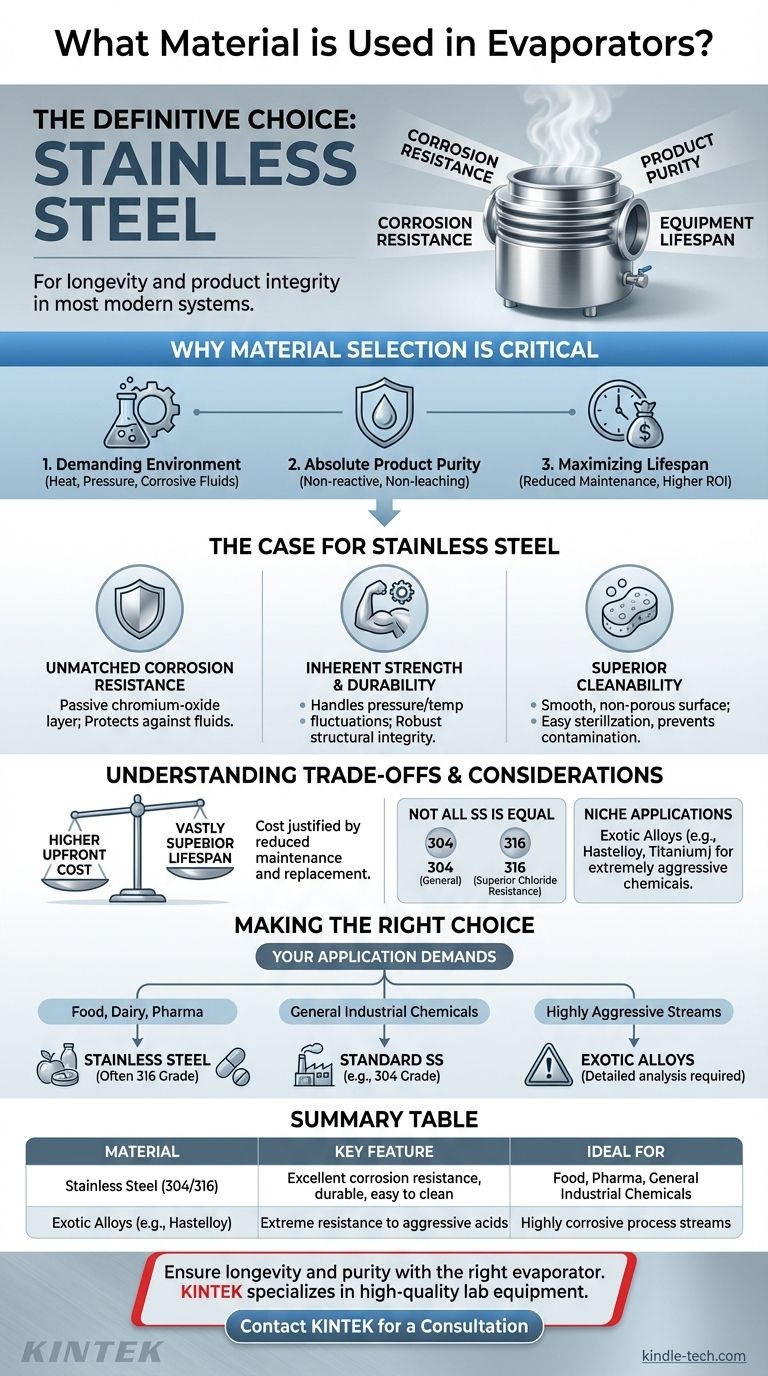

The definitive material used in most modern evaporator systems is stainless steel. This choice is not arbitrary; it is a direct result of stainless steel's excellent resistance to corrosion, which ensures both the longevity of the equipment and the purity of the product being processed.

The selection of an evaporator material is a critical engineering decision that balances chemical resistance, equipment lifespan, and product integrity. While other materials exist for niche applications, stainless steel provides the most reliable and cost-effective solution for a vast range of industries.

Why Material Selection is So Critical

An evaporator operates under demanding conditions that can quickly degrade substandard materials. Making the right choice is fundamental to ensuring a safe, efficient, and long-lasting operation.

The Demanding Internal Environment

Evaporators concentrate substances by boiling off a liquid, a process that involves constant exposure to heat, pressure changes, and often, corrosive process fluids. The material must be able to withstand these thermal and chemical stresses without failing.

Ensuring Absolute Product Purity

For industries like food, beverage, and pharmaceuticals, preventing any contamination of the product stream is non-negotiable. The evaporator's material must be non-reactive and non-leaching to guarantee the final product meets stringent quality and safety standards.

Maximizing Equipment Lifespan

The initial cost of an evaporator is significant. A material that resists corrosion and physical wear directly translates to a longer operational life, fewer maintenance cycles, and a much higher return on investment.

The Case for Stainless Steel

Stainless steel has become the industry standard for good reason. Its inherent properties make it uniquely suited to the challenges of evaporation systems.

Unmatched Corrosion Resistance

The key feature of stainless steel is its passive chromium-oxide layer. This invisible, self-healing film protects the underlying metal from attack by a wide variety of process fluids, preventing rust and degradation.

Inherent Strength and Durability

Beyond its chemical resistance, stainless steel is a robust material that can handle the pressures and temperature fluctuations common in evaporator systems. This structural integrity is vital for operational safety and reliability.

Superior Cleanability

The smooth, non-porous surface of stainless steel makes it easy to clean and sterilize. This is a crucial advantage for preventing microbial growth and cross-contamination between batches, especially in hygienic applications.

Understanding the Trade-offs and Considerations

While stainless steel is the dominant choice, a nuanced understanding of its properties and limitations is essential for proper application.

Not All Stainless Steel is Equal

Different grades of stainless steel exist for different applications. Austenitic grades like 304 and 316 are most common, with 316 offering superior resistance to chlorides (like saltwater), making it essential for marine or certain food processing applications.

The Upfront Cost Factor

Stainless steel carries a higher initial procurement cost compared to materials like carbon steel. However, this cost is almost always justified by its vastly superior lifespan and reduced need for maintenance and replacement.

When to Consider Other Materials

In rare cases involving extremely aggressive acids or other highly corrosive chemicals, even high-grade stainless steel may not be sufficient. For these niche applications, more exotic and expensive alloys like Hastelloy or titanium may be required.

Making the Right Choice for Your Application

Your final material decision should be guided by the specific demands of your process.

- If your primary focus is food, dairy, or pharmaceuticals: Stainless steel (often 316 grade) is the default choice due to its non-reactive surface and excellent cleanability.

- If your primary focus is general industrial chemicals: A standard grade of stainless steel (like 304) often provides the ideal balance of performance and cost-effectiveness.

- If your primary focus is managing highly aggressive process streams: You must conduct a detailed material compatibility analysis, as specialized alloys beyond stainless steel may be necessary to ensure safety and equipment life.

Ultimately, selecting the right evaporator material is a strategic investment in the long-term reliability and integrity of your process.

Summary Table:

| Material | Key Feature | Ideal For |

|---|---|---|

| Stainless Steel (304/316) | Excellent corrosion resistance, durable, easy to clean | Food, Pharma, General Industrial Chemicals |

| Exotic Alloys (e.g., Hastelloy) | Extreme resistance to aggressive acids | Highly corrosive process streams |

Ensure the longevity and purity of your processes with the right evaporator. The material is a critical investment in your lab's safety and efficiency. KINTEK specializes in high-quality lab equipment, including evaporators built with the optimal materials for your specific application.

Let our experts help you select the perfect equipment for your needs. Contact KINTEK today for a consultation and discover how our solutions can enhance your laboratory's performance.

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Performance Laboratory Stirrers for Diverse Applications

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- How do vacuum pumps enhance efficiency and performance? Boost Your System's Speed and Lower Costs

- What types of gases can a water circulating vacuum pump handle? Safely Manage Flammable, Condensable & Dirty Gases

- What can I use a vacuum pump for? Powering Industrial Processes from Packaging to Automation

- Why is a water circulating vacuum pump suitable for handling flammable or explosive gases? Inherent Safety Through Isothermal Compression

- What is the purpose of the compression chamber in a vacuum pump? The Heart of Vacuum Generation