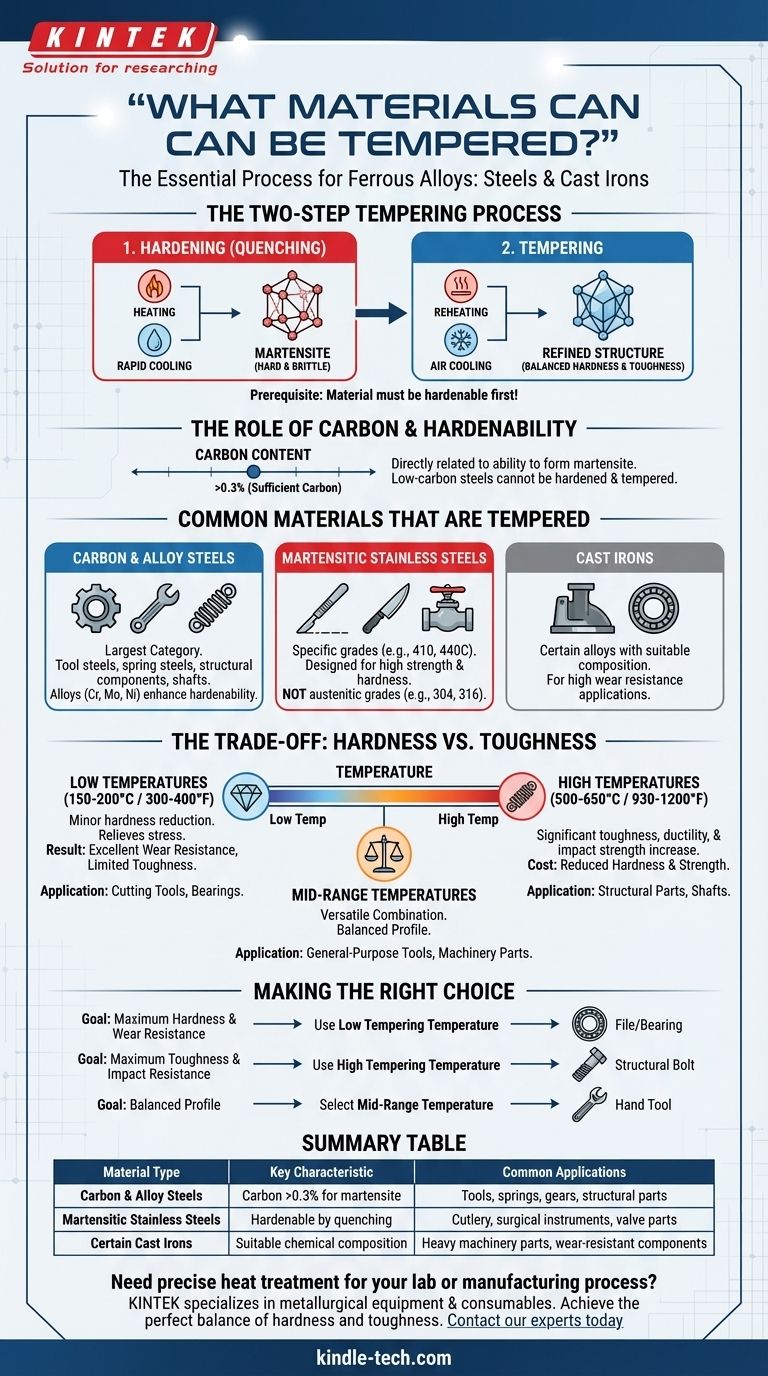

In metallurgy, the tempering process is applied almost exclusively to ferrous alloys—specifically, steels and cast irons that have first been hardened. While many materials undergo various heat treatments, the specific sequence of hardening followed by tempering is a defining characteristic of steel processing. It is this two-step combination that allows for the precise tailoring of mechanical properties.

The core principle is that tempering is not a standalone process. A material can only be tempered if it can first be hardened via quenching to create a very hard but brittle internal structure. Tempering then modifies this structure, sacrificing some hardness to gain essential toughness.

The Prerequisite for Tempering: Hardenability

Before a material can be tempered, it must be "hardenable" in a very specific way. This ability is the foundation of the entire process.

What is Hardening?

For steels, hardening involves heating the metal to a critical temperature where its internal crystal structure changes. It is then rapidly cooled, or quenched, in a medium like water, oil, or air.

This rapid cooling traps the carbon atoms in a highly stressed, needle-like crystal structure known as martensite.

Why Hardening Creates Brittleness

Martensite is extremely hard and wear-resistant, but it is also very brittle and contains significant internal stresses from its rapid formation.

In this state, the steel is often too brittle for most practical applications. An impact could cause it to shatter like glass rather than bend or deform. Tempering is the required solution to this problem.

The Role of Carbon

A steel's ability to form hard martensite—and thus its ability to be tempered—is directly related to its carbon content.

Generally, steels with sufficient carbon (typically above 0.3%) can be effectively hardened and subsequently tempered. Low-carbon steels lack the necessary carbon to form a fully martensitic structure and therefore do not benefit from this process.

Common Materials That Are Tempered

Based on the principle of hardenability, the list of temperable materials is almost entirely composed of specific steels and cast irons.

Carbon and Alloy Steels

This is the largest and most common category. The process is fundamental to creating a vast range of products.

Examples include tool steels, spring steels, cold-worked steels, and quenched and tempered (Q&T) steels used for structural components, gears, and shafts. The addition of alloys like chromium, molybdenum, and nickel enhances hardenability.

High-Alloy and Stainless Steels

Only certain grades of stainless steel can be tempered. Martensitic stainless steels (like 410 or 440C) are designed to be hardened and tempered to achieve high strength and hardness for applications like cutlery, surgical instruments, and valve parts.

In contrast, austenitic stainless steels (like 304 or 316) have a different crystal structure and cannot be hardened by quenching, so they are not tempered.

Cast Irons

Certain cast-iron alloys, particularly those with a suitable chemical composition and structure, can also be hardened and tempered.

This is common for components requiring high wear resistance, such as parts for heavy machinery or anti-friction bearings.

Understanding the Trade-off: Hardness vs. Toughness

Tempering is fundamentally a balancing act. The properties you achieve are a direct trade-off controlled by the tempering temperature.

The Effect of Tempering Temperature

After quenching, the steel is reheated to a temperature below its critical hardening temperature, held for a specific time, and then cooled.

- Low Temperatures (e.g., 150-200°C / 300-400°F): This relieves internal stresses with only a minor reduction in hardness. The result is a material with excellent wear resistance but limited toughness.

- High Temperatures (e.g., 500-650°C / 930-1200°F): This significantly increases toughness, ductility, and impact strength, but at the cost of reducing hardness and strength.

Dialing in the Final Properties

This relationship allows engineers and metallurgists to precisely "dial in" the desired mechanical properties for a specific application. A cutting tool needs to retain hardness, while a structural bolt needs toughness to handle impact loads.

By carefully selecting the tempering temperature, a single steel alloy can be adapted for dozens of different uses.

Making the Right Choice for Your Goal

The decision to temper and the temperature you choose should be driven entirely by the intended function of the final component.

- If your primary focus is maximum hardness and wear resistance: Use a low tempering temperature for materials intended for cutting tools, files, or bearing surfaces.

- If your primary focus is maximum toughness and impact resistance: Use a high tempering temperature for materials used in structural applications, shafts, or components that must endure shock loading.

- If your goal is a balanced profile: Select a mid-range tempering temperature to achieve a versatile combination of strength, hardness, and ductility for general-purpose hand tools or machinery parts.

Ultimately, tempering is the essential second step that transforms the raw, brittle strength of hardened steel into a refined and reliable engineering material.

Summary Table:

| Material Type | Key Characteristic | Common Applications |

|---|---|---|

| Carbon & Alloy Steels | Carbon content >0.3% for martensite formation | Tools, springs, gears, structural parts |

| Martensitic Stainless Steels | Can be hardened by quenching | Cutlery, surgical instruments, valve parts |

| Certain Cast Irons | Suitable chemical composition | Heavy machinery parts, wear-resistant components |

Need precise heat treatment for your lab or manufacturing process? KINTEK specializes in supplying the lab equipment and consumables necessary for metallurgical processes like tempering. Whether you're working with tool steels, stainless steels, or cast irons, we provide the reliable solutions you need to achieve the perfect balance of hardness and toughness. Contact our experts today to discuss how we can support your laboratory's specific material testing and processing requirements!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost