The short answer is that sintering is a remarkably versatile process compatible with a vast range of materials, primarily metals, ceramics, and their composites. The key requirement is that the material can be produced in a powdered form, which is then heated to bond the particles together without melting the primary constituent. This enables the creation of unique alloys and complex parts from materials that are otherwise difficult to work with.

Sintering's true power lies not just in the materials it can use, but in its ability to combine them. By starting with powders, you can create custom alloys and composite materials with precisely engineered properties that are often impossible to achieve through traditional melting and casting.

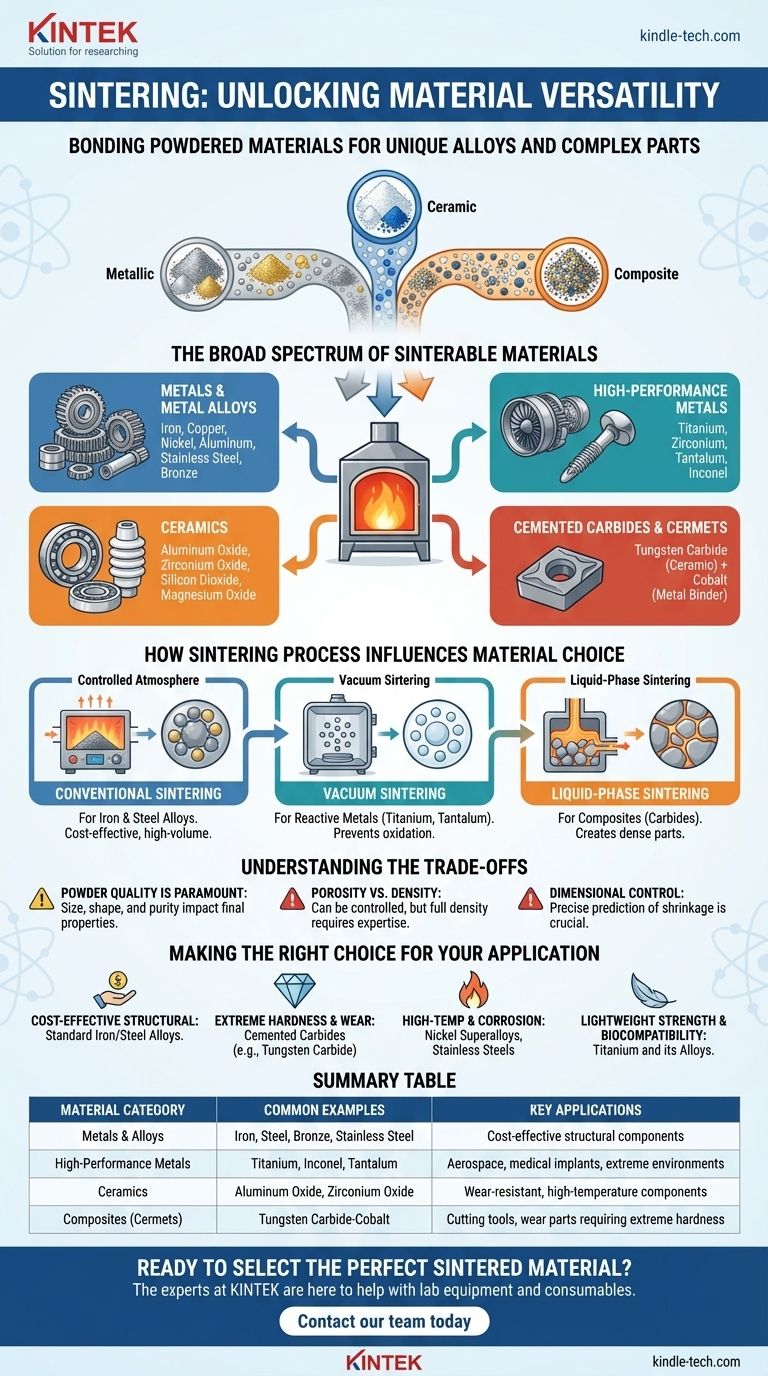

The Broad Spectrum of Sinterable Materials

Sintering is fundamentally about diffusion and bonding between particles. This principle applies across several major material families, each chosen for specific performance characteristics.

Metals and Metal Alloys

This is the most common category for sintered parts, valued for creating strong, net-shape components efficiently.

Common base metals include iron, copper, nickel, and aluminum. These are often blended to create alloys with specific properties directly from the powder stage.

Popular alloys include carbon steels, stainless steels (like 316L and 17-4PH), bronze, and various iron-copper or iron-nickel steels.

High-Performance and Refractory Metals

Sintering is particularly valuable for metals with extremely high melting points or high reactivity, which makes them difficult to melt and cast.

This group includes titanium, zirconium, tantalum, and beryllium. It also includes superalloys designed for extreme environments, such as Inconel 718.

Ceramics

Ceramic sintering is used to produce hard, wear-resistant, and heat-resistant components for technical and industrial applications.

Examples include aluminum oxide, zirconium oxide, silicon dioxide, and magnesium oxide. Even materials like glass and iron oxide can be processed through sintering.

Cemented Carbides and Cermets

This special class of composites combines the hardness of a ceramic with the toughness of a metal binder, creating materials ideal for cutting tools and wear parts.

The most prominent example is tungsten carbide (a ceramic), which is sintered with a cobalt (a metal) binder that melts and flows between the carbide grains.

How the Sintering Process Influences Material Choice

The specific sintering technique used is often dictated by the material's properties. Understanding this connection is key to successful manufacturing.

Conventional Sintering

This process, often performed in a controlled atmosphere furnace, is the workhorse for common materials like iron and steel alloys. It's a cost-effective method for high-volume production.

Vacuum Sintering

Reactive or refractory metals like titanium and tantalum are prone to oxidizing at high temperatures. Sintering them in a vacuum furnace prevents this contamination, preserving the material's integrity and performance.

Liquid-Phase Sintering

This technique is essential for composite materials where one constituent has a lower melting point than the other. It's the standard method for cemented carbides, where the cobalt binder melts to create a dense, strong part.

Understanding the Trade-offs

While powerful, sintering is not without its considerations. The final properties of a sintered part are directly tied to the process and the starting materials.

Powder Quality is Paramount

The size, shape, and purity of the initial powder particles have a significant impact on the final density, strength, and surface finish of the component. Inconsistent powder leads to inconsistent parts.

Porosity vs. Density

Sintering can be controlled to produce parts with a specific level of porosity, which is useful for applications like filters. However, achieving full density for maximum strength can be challenging and may require secondary operations.

Dimensional Control

Parts shrink during the sintering process as the particles bond and densify. This shrinkage must be precisely predicted and controlled to achieve accurate final dimensions, which requires significant expertise.

Making the Right Choice for Your Application

Selecting the right material is a function of your end goal. The versatility of sintering provides a solution for a wide range of engineering challenges.

- If your primary focus is cost-effective structural components: Standard iron and steel-based powder alloys offer an excellent balance of strength and manufacturability.

- If your primary focus is extreme hardness and wear resistance: Cemented carbides, like tungsten carbide with a cobalt binder, are the definitive choice for cutting tools and dies.

- If your primary focus is high-temperature performance or corrosion resistance: Nickel-based superalloys like Inconel or stainless steels are ideal.

- If your primary focus is lightweight strength and biocompatibility: Titanium and its alloys are the go-to materials, especially for aerospace and medical implants.

Ultimately, viewing sintering as a powder-based process unlocks a world of material possibilities far beyond what traditional manufacturing can offer.

Summary Table:

| Material Category | Common Examples | Key Applications |

|---|---|---|

| Metals & Alloys | Iron, Steel, Bronze, Stainless Steel | Cost-effective structural components |

| High-Performance Metals | Titanium, Inconel, Tantalum | Aerospace, medical implants, extreme environments |

| Ceramics | Aluminum Oxide, Zirconium Oxide | Wear-resistant, high-temperature components |

| Composites (Cermets) | Tungsten Carbide-Cobalt | Cutting tools, wear parts requiring extreme hardness |

Ready to select the perfect sintered material for your application? The experts at KINTEK are here to help. We specialize in providing the lab equipment and consumables necessary for successful sintering processes, from material selection to final part production.

Contact our team today to discuss your project's requirements and discover how our solutions can enhance your lab's capabilities and drive your innovation forward.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability