There is no single material that all crucibles must be made of. The correct material for a crucible is entirely dictated by its intended use, specifically the maximum temperature it must withstand and the chemical properties of the substance it will hold. Common materials range from graphite and silicon carbide for metal casting to high-purity ceramics and platinum for laboratory analysis.

A crucible's design is a calculated decision, not a default choice. The fundamental requirements are that it must have a melting point significantly higher than the material being heated and that it must remain chemically non-reactive with that material at peak temperature to prevent failure and contamination.

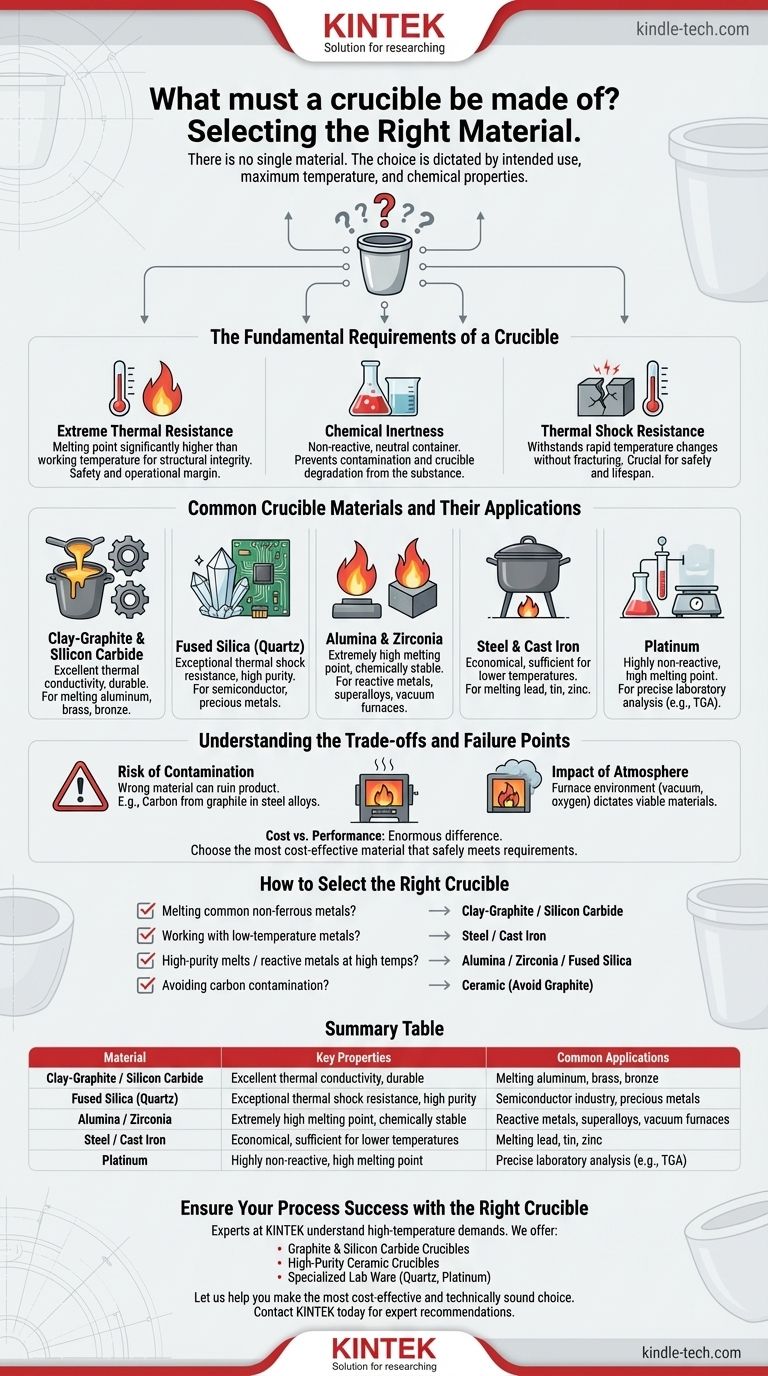

The Fundamental Requirements of a Crucible

Choosing a crucible material involves evaluating its ability to survive extreme conditions. Three core properties are non-negotiable for any successful high-temperature application.

Extreme Thermal Resistance

The most basic requirement is that the crucible does not melt or soften. The material's melting point must be substantially higher than the working temperature of the process.

This provides a critical safety and operational margin, ensuring the crucible maintains its structural integrity while holding molten contents.

Chemical Inertness

A crucible must act as a neutral container. It cannot react with, corrode, or dissolve into the substance being heated.

This chemical incompatibility, known as being chemically inert, is essential to prevent contamination of the melt and the rapid degradation of the crucible itself. For example, melting highly reactive titanium requires a crucible made of a very stable ceramic, not a material it can easily form an alloy with.

Thermal Shock Resistance

Materials expand when heated and contract when cooled. If this happens too quickly, or unevenly, internal stresses can cause the material to crack and fail catastrophically.

A crucible must have high thermal shock resistance to withstand rapid temperature changes without fracturing, which is crucial for both safety and the crucible's lifespan.

Common Crucible Materials and Their Applications

Different materials excel under different conditions, leading to a wide array of specialized crucibles.

Clay-Graphite and Silicon Carbide

These are the workhorses of foundries for melting non-ferrous metals like aluminum, brass, and bronze.

Graphite provides excellent thermal conductivity for efficient melting, while the clay or silicon carbide binder adds strength and durability. They offer a superb balance of performance and cost for general-purpose metal casting.

Fused Silica (Quartz)

Known for exceptional thermal shock resistance, fused silica crucibles are often used for high-purity applications, such as in the semiconductor industry or for melting precious metals.

They are chemically very pure but can become brittle (devitrify) if held at very high temperatures for extended periods.

Alumina and Zirconia

These advanced ceramic crucibles are chosen for their extremely high melting points and excellent chemical stability.

They are ideal for melting reactive metals, superalloys, or materials in vacuum furnace applications where contamination must be minimized and temperatures can exceed 1600°C (2900°F).

Steel and Cast Iron

For lower-temperature applications, simple metallic crucibles are effective and economical.

A steel or cast iron pot is perfectly suitable for melting metals with low melting points, such as lead, tin, or zinc, where the crucible's melting point is still far above the working temperature.

Platinum

For highly precise laboratory work, such as thermogravimetric analysis (TGA), platinum crucibles are the standard.

While expensive, platinum has a high melting point and is extremely non-reactive, ensuring that analytical results are not skewed by crucible contamination.

Understanding the Trade-offs and Failure Points

Selecting the wrong crucible is one of the most common points of failure in high-temperature work. Understanding the risks is key to making the right choice.

The Risk of Contamination

The wrong crucible can ruin your final product. A clay-graphite crucible, for example, can introduce small amounts of carbon into a melt, which may be unacceptable for certain steel alloys. A ceramic crucible that begins to break down can release inclusions into the melt, weakening the final cast part.

The Impact of Atmosphere

The environment inside the furnace is just as important as the temperature. A graphite crucible performs well in a vacuum or fuel-fired furnace but will rapidly oxidize and burn away in an oxygen-rich electric furnace. The furnace atmosphere dictates which materials are viable.

Cost vs. Performance

There is an enormous cost difference between materials. A small cast iron pot might cost a few dollars, while a similarly sized platinum crucible can cost thousands. The goal is not to buy the most advanced crucible but the most cost-effective material that safely meets all technical requirements of your specific process.

How to Select the Right Crucible

Your selection process should be a simple checklist based on your material, temperature, and desired outcome.

- If your primary focus is melting common non-ferrous metals (like aluminum or brass): Your best starting point is a clay-graphite or silicon carbide crucible.

- If your primary focus is working with low-temperature metals (like lead or zinc): A simple steel or cast iron crucible is sufficient and highly economical.

- If your primary focus is high-purity melts or reactive metals at very high temperatures: You must use an advanced ceramic like alumina, zirconia, or fused silica.

- If your primary focus is avoiding carbon contamination in a specific alloy: Do not use a graphite-based crucible; opt for a ceramic or other suitable material instead.

Choosing the correct crucible is the foundation for a successful, safe, and uncontaminated high-temperature process.

Summary Table:

| Material | Key Properties | Common Applications |

|---|---|---|

| Clay-Graphite / Silicon Carbide | Excellent thermal conductivity, durable | Melting aluminum, brass, bronze |

| Fused Silica (Quartz) | Exceptional thermal shock resistance, high purity | Semiconductor industry, precious metals |

| Alumina / Zirconia | Extremely high melting point, chemically stable | Reactive metals, superalloys, vacuum furnaces |

| Steel / Cast Iron | Economical, sufficient for lower temperatures | Melting lead, tin, zinc |

| Platinum | Highly non-reactive, high melting point | Precise laboratory analysis (e.g., TGA) |

Ensure Your Process Success with the Right Crucible

Selecting the correct crucible is critical for achieving uncontaminated results, ensuring operator safety, and protecting your equipment. The experts at KINTEK understand the precise demands of high-temperature applications, from metal casting to sophisticated laboratory analysis.

We provide a wide range of high-performance crucibles tailored to your specific needs:

- Graphite & Silicon Carbide Crucibles for efficient non-ferrous metal melting.

- High-Purity Ceramic Crucibles (Alumina, Zirconia) for reactive metals and extreme temperatures.

- Specialized Lab Ware including quartz and platinum crucibles for analytical precision.

Let us help you make the most cost-effective and technically sound choice. Our team can guide you to the perfect crucible material for your temperature, chemical, and purity requirements.

Contact KINTEK today to discuss your application and get expert recommendations for your laboratory or production needs.

Visual Guide

Related Products

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- High Purity Pure Graphite Crucible for Evaporation

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- Why are alumina crucibles or baskets essential for Boudouard reaction studies? Ensure Pure Data & Chemical Inertness

- What are crucibles used for in the laboratory? Essential Tools for High-Temperature Processing

- When should I replace my crucible? A Guide to Prevent Costly Failures

- How long will a crucible last? Maximize Its Lifespan from 15 to 100+ Heats

- Why must high-purity graphite crucibles be treated in a vacuum oven and pre-baked? Ensure Pure Molten Salt Experiments

- What is the classification of a crucible furnace? A Guide to Fuel-Fired, Electric & Induction Types

- Why are alumina crucibles and vertical electric furnaces used for lithium borate melting? Ensure Purity & Stability

- What metal is best for a crucible? Match Your Material to the Perfect Crucible for Superior Melts