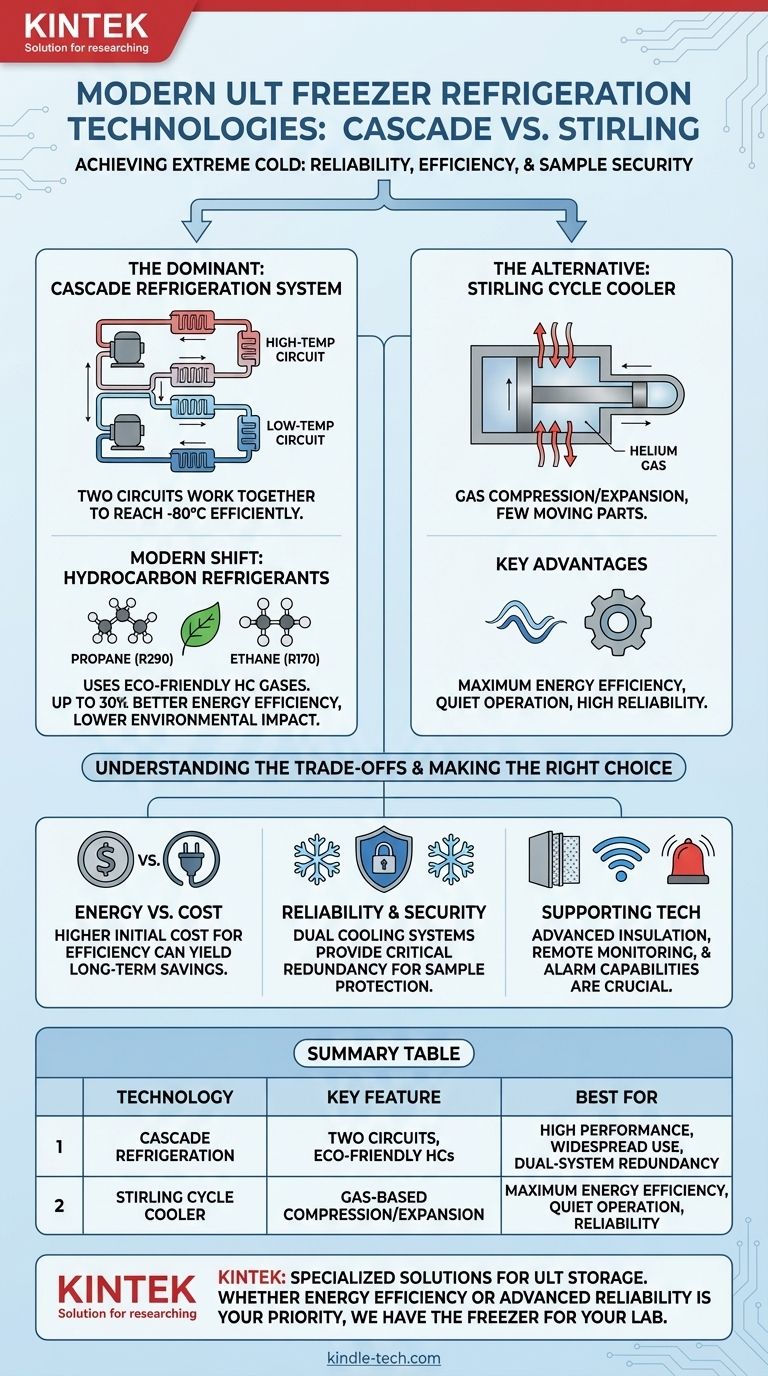

At the core of a modern Ultra-Low Temperature (ULT) freezer, you will find one of two primary refrigeration technologies: a highly refined cascade refrigeration system or a Stirling cycle cooler. The vast majority of units today rely on cascade systems, which have evolved to use efficient and environmentally friendly hydrocarbon refrigerants like propane and ethane, a significant improvement over older CFC/HFC-based fluids.

The central challenge in ULT freezer design is achieving extreme cold reliably and efficiently. Modern technologies have moved beyond simply reaching -80°C to focus on minimizing energy consumption, improving sample security, and reducing environmental impact.

The Dominant Technology: Cascade Refrigeration

Most ULT freezers on the market use a cascade refrigeration system. This proven technology uses two separate cooling circuits that work together to reach ultra-low temperatures.

How a Cascade System Works

Think of it as two freezers stacked on top of each other. The first, high-temperature circuit cools the condenser of the second, low-temperature circuit. This pre-cooling allows the second circuit to reach the target temperature of -80°C far more efficiently than a single system ever could.

The Modern Shift to Hydrocarbon Refrigerants

Historically, these systems used chlorofluorocarbon (CFC) or hydrofluorocarbon (HFC) refrigerants, which are potent greenhouse gases. Modern systems now use natural hydrocarbon (HC) refrigerants like propane and ethane.

These gases are chosen for their excellent thermodynamic properties, including their ability to be liquefied easily. Most importantly, they have a minimal impact on the environment compared to their predecessors.

Efficiency and Environmental Benefits

Switching to HC refrigerants can improve a freezer's energy efficiency by up to 30% over older CFC/HFC systems. This directly translates to lower operating costs and a smaller carbon footprint for the lab.

The Alternative: Stirling Cycle Coolers

A less common but highly effective alternative is the Stirling cycle cooler. This technology operates on a completely different principle from compressor-based systems.

A Fundamentally Different Approach

A Stirling cooler uses a fixed amount of a gas (like helium) that is continuously compressed and expanded within a sealed system to move heat from the inside of the freezer to the outside. It does not use liquid refrigerants or traditional compressors.

Key Advantages

The primary benefit of a Stirling cooler is its simplicity and reliability, as it has very few moving parts. This design often leads to greater energy efficiency and quieter operation compared to many cascade systems.

Understanding the Trade-offs

Choosing the right ULT freezer involves balancing performance, cost, and long-term reliability. Each technology presents a different set of considerations.

Energy Consumption vs. Initial Cost

While cascade systems are powerful, they can consume up to 20 times more energy than a standard household refrigerator. High-efficiency models, whether advanced cascade or Stirling-based, may have a higher purchase price but deliver significant savings in long-term energy costs.

Reliability and Sample Security

A standard cascade system has two compressors, creating two potential points of failure. To mitigate this risk, many modern freezers offer dual cooling systems, where two independent refrigeration systems can each maintain the target temperature, providing critical redundancy to protect invaluable samples.

Supporting Technologies Are Crucial

The refrigeration method is only part of the story. Modern freezers rely on a suite of supporting features to ensure performance and safety. These include advanced, high-performance insulation, sophisticated remote monitoring systems, and alarm capabilities that alert staff to any temperature deviations before samples are compromised.

Making the Right Choice for Your Lab

Your laboratory's specific priorities should guide your decision when evaluating ULT freezer technology.

- If your primary focus is maximum energy efficiency and sustainability: Look for models using natural hydrocarbon refrigerants or investigate the long-term cost benefits of a Stirling cycle cooler.

- If your primary focus is the absolute security of irreplaceable samples: Prioritize a freezer with a dual cooling system for redundancy, backed by a robust remote monitoring and alarm system.

- If your primary focus is minimizing long-term operating costs: Conduct a total cost of ownership analysis that weighs the higher initial price of an energy-efficient model against its lower electricity consumption over its lifespan.

Ultimately, understanding the core technology inside the freezer empowers you to select a unit that aligns perfectly with your lab's operational, financial, and scientific goals.

Summary Table:

| Technology | Key Feature | Best For |

|---|---|---|

| Cascade Refrigeration | Uses two circuits with eco-friendly hydrocarbon refrigerants (propane/ethane) | High performance, widespread use, dual-system redundancy |

| Stirling Cycle Cooler | Gas-based compression/expansion with few moving parts | Maximum energy efficiency, quiet operation, reliability |

Need a reliable ULT freezer tailored to your lab's priorities? Whether you require energy-efficient cascade systems with hydrocarbon refrigerants or the advanced reliability of Stirling coolers, KINTEK specializes in lab equipment to meet your ultra-low temperature storage needs. Contact us today to find the perfect solution for sample security, sustainability, and cost-efficiency.

Visual Guide

Related Products

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

- 108L Vertical Ultra Low Temperature ULT Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

People Also Ask

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity