The most critical safety features in ultra-low temperature (ULT) freezers are designed to prevent the catastrophic loss of valuable samples. This is accomplished through a combination of redundant cooling systems that act as a fail-safe, advanced alarm and monitoring networks that provide immediate alerts for any deviation, and robust physical construction that maintains temperature during power failures.

The core principle of ULT freezer safety is not a single feature, but an integrated system. It combines hardware redundancy to prevent complete failure with intelligent monitoring to provide early warnings, ensuring the integrity and preservation of critical materials is the absolute priority.

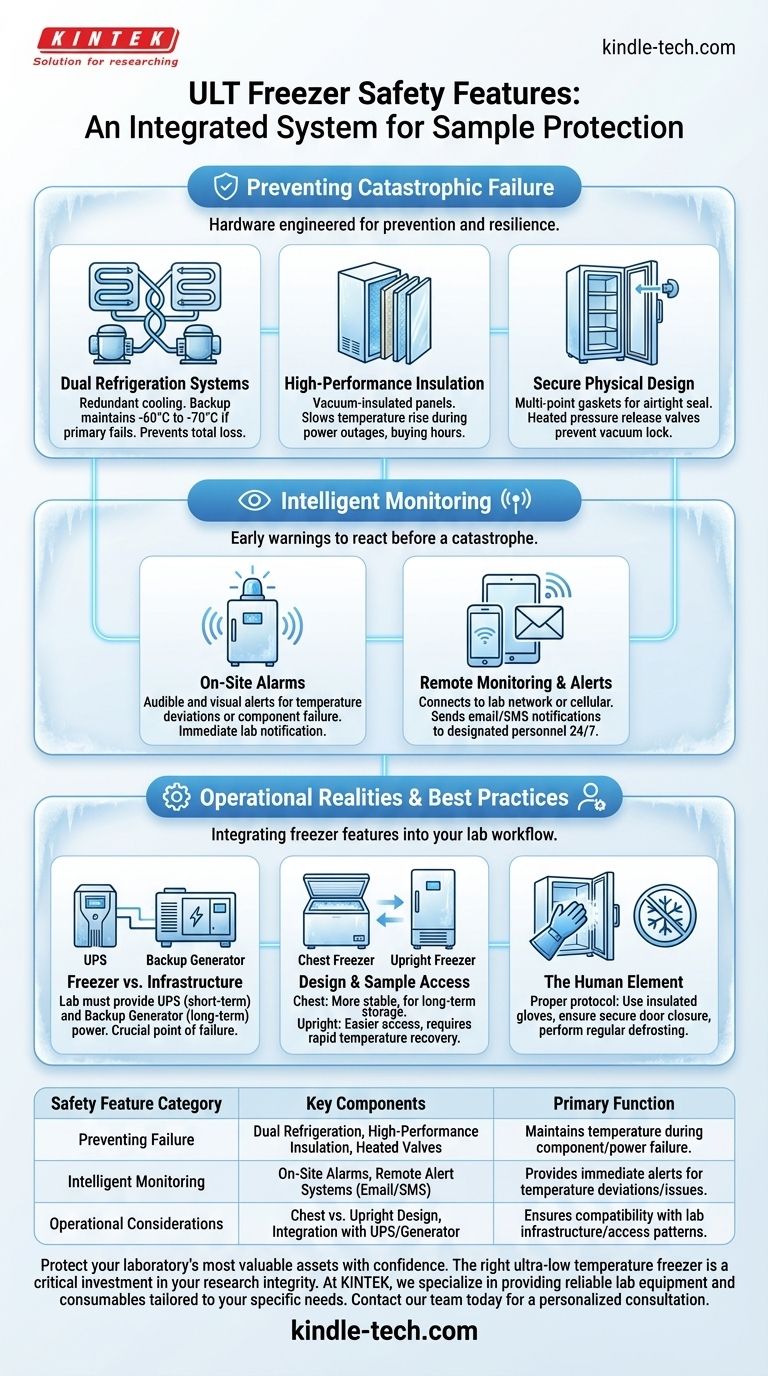

The Foundation: Preventing Catastrophic Failure

The first line of defense in a ULT freezer is the hardware engineered to maintain temperature no matter what. These features are designed for prevention and resilience.

Dual Refrigeration Systems

Most high-quality ULT freezers utilize a dual or cascade refrigeration system. These are two independent cooling circuits working in tandem.

If one compressor or system fails, the backup system can typically maintain a temperature around -60°C to -70°C. This prevents a total loss and provides a critical window of time to arrange for repairs or transfer samples.

High-Performance Insulation

The freezer's ability to hold its temperature during a power outage is a crucial passive safety feature. Modern units use advanced insulation, such as vacuum-insulated panels.

This robust construction dramatically slows the rate of temperature rise, buying several hours before samples are compromised.

Secure Physical Design

A freezer's physical integrity is key to its stability. This includes multi-point gaskets on the door to create an airtight seal, preventing ambient air from leaking in.

Many units also include heated pressure release valves. These prevent a vacuum from forming after the door is closed, ensuring staff can always access the samples when needed.

The Alert System: Intelligent Monitoring

While hardware prevents failure, monitoring systems provide the early warnings necessary to react to a problem before it becomes a catastrophe.

On-Site Alarms

Nearly all ULT freezers are equipped with audible and visual alarms. These will activate if the internal temperature moves outside a pre-set range or if there is a component failure.

This provides an immediate, on-site alert to any lab personnel who are present.

Remote Monitoring and Alerts

For events that occur after hours, remote alert systems are essential. These systems connect to the lab's network or a cellular service.

When an alarm condition is triggered, the freezer automatically sends a notification via email or text message to a designated list of personnel, ensuring a rapid response at any time of day.

Understanding the Operational Realities

The features built into a freezer are only part of a comprehensive sample safety strategy. How you integrate it into your lab's workflow is just as important.

Freezer Features vs. Lab Infrastructure

A key distinction to make is between the freezer's capabilities and the lab's infrastructure. A freezer cannot create its own backup power.

Your facility must provide an uninterruptible power supply (UPS) for short-term outages and have a backup generator for long-term power loss. This is the most common point of failure.

Design and Sample Access

The physical design of the freezer impacts safety. Chest freezers lose less cold air when opened, making them inherently more stable and better suited for long-term, infrequent-access storage.

Upright freezers are more common due to their smaller footprint and easier access to samples, but they experience greater temperature fluctuations when the door is opened. Rapid temperature recovery after a door opening is a critical feature for these models.

The Human Element

Proper user protocol is a final layer of safety. This includes using insulated gloves to prevent cold burns, ensuring the door is always closed securely, and performing regular maintenance like defrosting to prevent ice buildup that can compromise the door seal.

Making the Right Choice for Your Goal

Selecting a freezer requires you to match its features with the value and use case of your samples.

- If your primary focus is irreplaceable, long-term samples: Prioritize a unit with a dual refrigeration system and consider a chest freezer design for maximum temperature stability.

- If your primary focus is frequently accessed materials: An upright freezer with robust door gaskets, frost-reduction features, and rapid temperature recovery is essential.

- If your primary focus is operational security and compliance: Ensure the freezer has advanced remote monitoring, comprehensive data logging, and secure, lockable handles.

Ultimately, selecting the right ULT freezer means evaluating how its integrated safety features align with your lab's specific operational needs and risk tolerance.

Summary Table:

| Safety Feature Category | Key Components | Primary Function |

|---|---|---|

| Preventing Failure | Dual Refrigeration Systems, High-Performance Insulation, Heated Pressure Release Valves | Maintains temperature during component failure or power loss. |

| Intelligent Monitoring | On-Site Alarms, Remote Alert Systems (Email/SMS) | Provides immediate alerts for temperature deviations or system issues. |

| Operational Considerations | Chest vs. Upright Design, Integration with Lab UPS/Generator | Ensures compatibility with lab infrastructure and sample access patterns. |

Protect your laboratory's most valuable assets with confidence. The right ultra-low temperature freezer is a critical investment in your research integrity. At KINTEK, we specialize in providing reliable lab equipment and consumables tailored to your specific needs. Our experts can help you select a ULT freezer with the perfect combination of safety features—from redundant cooling systems to advanced remote monitoring—to match your lab's workflow and risk tolerance. Don't leave your samples to chance. Contact our team today for a personalized consultation and ensure your materials are preserved with maximum security.

Visual Guide

Related Products

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage