By definition, Cold Isostatic Pressing (CIP) is performed at or near ambient room temperature. The term "cold" is used to sharply contrast it with processes like Hot Isostatic Pressing (HIP), which operate at extremely high temperatures. The transformative work in CIP is achieved not through thermal energy, but through the immense and uniform application of pressure.

The name "Cold Isostatic Pressing" can be misleading. It does not imply cryogenic conditions, but rather signifies that the entire compaction process occurs at room temperature, relying solely on extreme hydrostatic pressure to form a preliminary part.

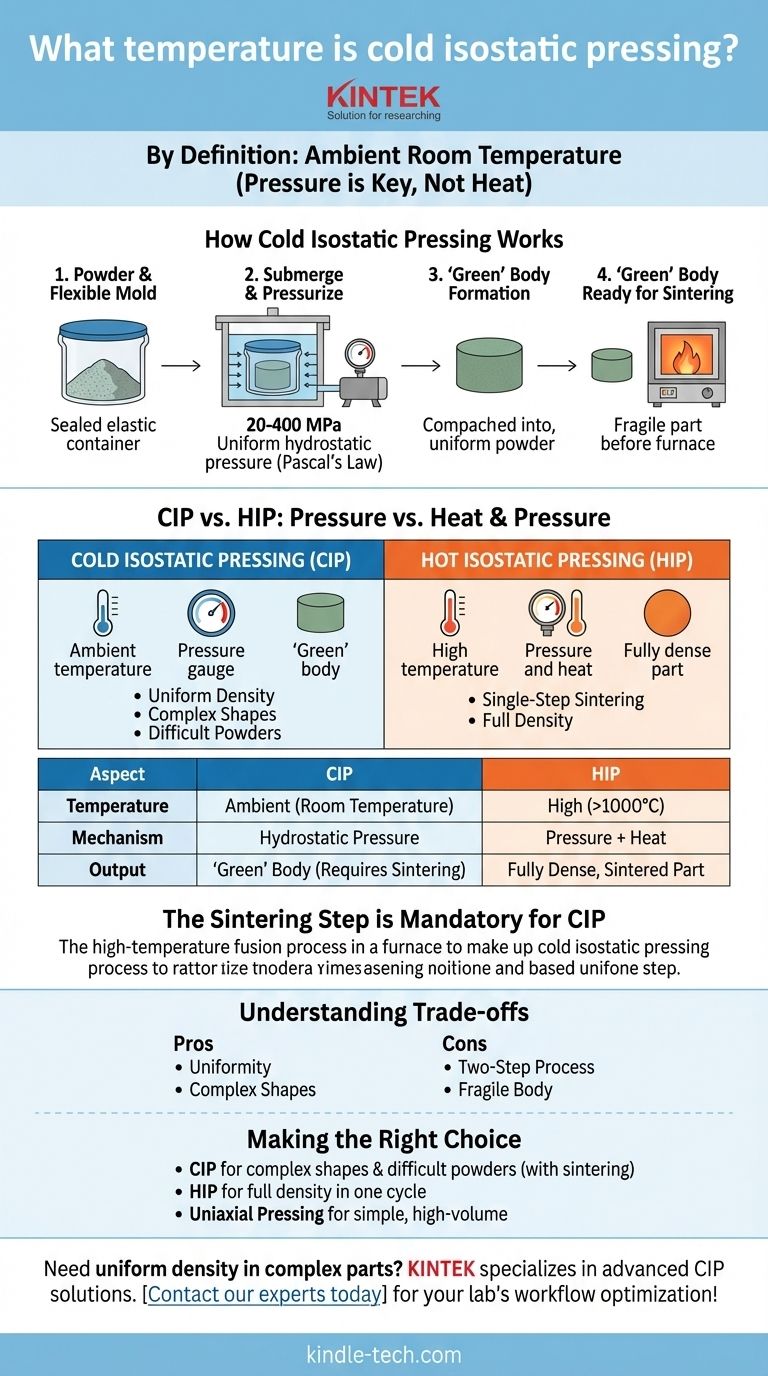

How Cold Isostatic Pressing Works

To understand why temperature is not a factor, you must first understand the mechanism. CIP is a method of compacting powders into a solid mass before they undergo final heat treatment.

The Core Principle: Pascal's Law

The process functions on Pascal's law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

This means the powder is squeezed equally from all directions, which is why the process is called "isostatic," meaning uniform pressure.

The Process Step-by-Step

First, a powder is placed into a flexible, elastomeric mold, which is then sealed, often under vacuum.

This sealed mold is submerged in a pressure chamber filled with a liquid, typically water mixed with a corrosion inhibitor. An external pump then pressurizes this fluid to immense levels, often between 20 and 400 MPa.

The extreme hydrostatic pressure collapses the mold, compacting the powder inside it uniformly.

The Result: The "Green" Body

The output of the CIP process is a compacted powder form known as a "green" body.

This part has a uniform density and the shape of the mold, but the individual powder particles have only been mechanically interlocked, not metallurgically bonded. It has some integrity but is relatively fragile.

The Critical Distinction: Pressure vs. Heat

The fundamental difference between CIP and other methods is its reliance on mechanical force alone. This has significant implications for the overall manufacturing workflow.

"Cold" Simply Means No Added Heat

CIP is a purely mechanical compaction process. The entire cycle of loading, pressurizing, and depressurizing occurs at the ambient temperature of the workshop.

Contrasting with Hot Isostatic Pressing (HIP)

This is in direct opposition to Hot Isostatic Pressing (HIP). HIP combines extreme pressure with very high temperatures, often over 1,000°C.

In HIP, the heat and pressure are applied simultaneously, allowing for both powder consolidation and sintering (the fusing of particles) to occur in a single step.

The Mandatory Next Step: Sintering

Because CIP does not use heat, the resulting "green" body must undergo a separate, subsequent high-temperature process called sintering.

During sintering, the green part is heated in a furnace, causing the powder particles to fuse together and form a strong, dense, final component. CIP and sintering are two distinct steps of a complete process.

Understanding the Trade-offs

CIP is a powerful technique, but it is not the solution for every scenario. Its advantages are directly tied to its limitations.

Advantage: Uniform Density and Complex Shapes

The primary benefit of CIP is its ability to produce parts with exceptionally uniform green density, even with complex geometries. This is very difficult to achieve with methods like uniaxial pressing, which compacts from one direction.

Advantage: Application with Difficult Powders

CIP is highly effective for compacting materials that are very hard and resist other forms of pressing, such as hard metals or ceramics.

Limitation: A Two-Step Process

The biggest trade-off is the requirement for a separate sintering step. This makes the total manufacturing cycle longer and more complex compared to an integrated process like HIP.

Limitation: Green Body Handling

The resulting "green" bodies are not at their final strength and can be fragile. They require careful handling between the CIP unit and the sintering furnace to prevent damage.

Making the Right Choice for Your Goal

Selecting the correct powder consolidation method depends entirely on your material, part complexity, and production requirements.

- If your primary focus is creating complex shapes with uniform density from difficult-to-press powders: CIP is an excellent choice, as long as you account for the subsequent sintering step.

- If your primary focus is achieving full density and final material properties in a single cycle: Hot Isostatic Pressing (HIP) is the more direct and appropriate technology.

- If your primary focus is high-volume production of simple, robust shapes: Traditional uniaxial die pressing may be a more cost-effective and faster alternative.

Understanding this distinction between pressure-driven compaction and thermal fusion is the key to leveraging advanced materials processing effectively.

Summary Table:

| Aspect | Cold Isostatic Pressing (CIP) | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Temperature | Ambient (Room Temperature) | High (Often > 1000°C) |

| Primary Mechanism | Hydrostatic Pressure | Pressure + Heat |

| Output | 'Green' Body (Requires Sintering) | Fully Dense, Sintered Part |

| Key Advantage | Uniform Density in Complex Shapes | Single-Step Consolidation & Sintering |

Need to achieve uniform density in complex ceramic or metal parts? KINTEK specializes in advanced laboratory equipment, including Cold Isostatic Pressing solutions. Our expertise ensures you get the right technology for your specific powder compaction and sintering needs, helping you produce high-integrity components efficiently. Contact our experts today to discuss how CIP can optimize your lab's workflow!

Visual Guide

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the dry bag process? A Guide to High-Speed Isostatic Pressing

- How big is the isostatic pressing market? A Deep Dive into the $1.2B+ Advanced Manufacturing Enabler

- What is CIP in powder metallurgy? Unlock Uniform Density for Complex Parts

- What is HIP and CIP in powder metallurgy? Choose the Right Process for Your Materials

- What is the difference between wet bag and dry bag isostatic pressing? Flexibility vs. High-Volume Production

- What is an isostatic press used for? Achieve Uniform Density & Eliminate Defects

- What is cold sintering? A Low-Energy Path to Novel Composite Materials

- What is the cold isostatic press process? Create Uniform, High-Integrity Parts