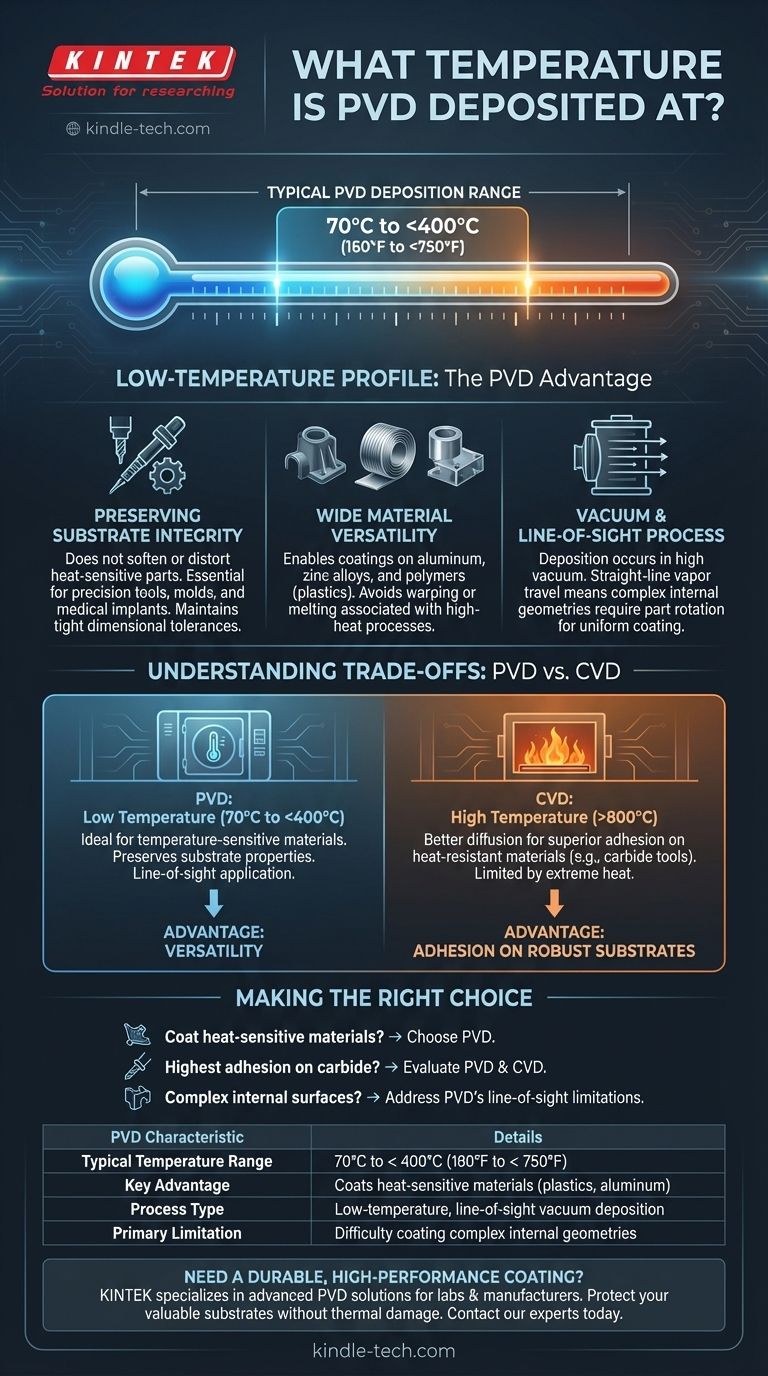

The deposition temperature for Physical Vapor Deposition (PVD) typically falls within a range of 70°C to just under 400°C (approximately 160°F to 750°F). This relatively low-temperature profile is a defining characteristic of the PVD process, making it exceptionally versatile for a wide array of materials.

PVD is fundamentally a low-temperature, "line-of-sight" vacuum deposition process. Its key advantage is the ability to apply high-performance coatings to heat-sensitive materials, such as plastics and certain metal alloys, without altering their fundamental properties.

Why PVD's Temperature Range is a Critical Advantage

The operating temperature of a coating process is not just a technical detail; it is a primary factor that determines what materials can be successfully coated. PVD's low-temperature nature unlocks several key benefits.

Preserving Substrate Integrity

Because PVD operates well below the tempering or annealing temperatures of most metals, it does not soften, distort, or change the microstructure of the underlying part. This is critical for components with tight dimensional tolerances, such as precision tools, molds, and medical implants.

Enabling a Wide Range of Materials

The process is not limited to high-strength steels. PVD's gentle temperature profile makes it the go-to solution for applying durable or decorative coatings onto materials that would be damaged by higher heat.

This includes common engineering materials like aluminum, zinc alloys, and even polymers (plastics), which would warp or melt in other high-temperature processes.

Understanding the Process Environment

PVD takes place in a high-vacuum chamber. The material to be deposited is turned into a vapor through a physical method (like sputtering with ions or evaporation with heat) and travels in a straight line to coat the target part.

The chamber temperature is precisely controlled not to cause a chemical reaction, but to influence the coating's final structure, density, and adhesion. This is a fundamental difference from high-temperature processes like Chemical Vapor Deposition (CVD).

Understanding the Trade-offs

No single process is perfect for every application. Understanding the limitations of PVD in the context of its temperature provides a complete picture.

PVD vs. High-Temperature CVD

While PVD's low temperature is a significant advantage for versatility, a process like CVD operates at much higher temperatures (often >800°C). This extreme heat can promote better diffusion of the coating into the substrate, sometimes resulting in superior adhesion for very specific applications, like coatings on carbide cutting tools.

However, this benefit comes at the cost of being restricted to materials that can withstand such extreme heat.

The "Line-of-Sight" Limitation

PVD is a "line-of-sight" process. The coating vapor travels in a straight path from the source to the substrate. This means that complex internal geometries or deep, narrow holes can be difficult to coat uniformly without complex part rotation and fixturing.

This is a physical limitation of the process, distinct from temperature, but is a critical consideration when selecting PVD for a component.

Making the Right Choice for Your Goal

Your decision to use PVD should be based on your substrate material and the functional requirements of the coating.

- If your primary focus is coating heat-sensitive materials: PVD is the definitive choice due to its low deposition temperature, which protects plastics, aluminum, and other alloys from damage.

- If your primary focus is achieving the highest possible adhesion on a robust material (like carbide): You should evaluate both PVD and high-temperature CVD, as CVD may offer specific adhesion benefits for your use case.

- If your part has complex, non-visible surfaces: You must engineer a solution to address PVD's line-of-sight nature, potentially involving specialized fixtures or considering an alternative, non-line-of-sight process.

By understanding the role of temperature, you can effectively select the right coating technology to meet your precise engineering requirements.

Summary Table:

| PVD Characteristic | Details |

|---|---|

| Typical Temperature Range | 70°C to < 400°C (160°F to < 750°F) |

| Key Advantage | Coats heat-sensitive materials (plastics, aluminum) |

| Process Type | Low-temperature, line-of-sight vacuum deposition |

| Primary Limitation | Difficulty coating complex internal geometries |

Need a durable, high-performance coating for your heat-sensitive components? KINTEK specializes in advanced PVD solutions for laboratories and manufacturers. Our expertise ensures your plastics, aluminum alloys, and precision parts receive superior coatings without thermal damage. Contact our experts today to discuss how our lab equipment and consumables can enhance your coating processes and protect your valuable substrates.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition