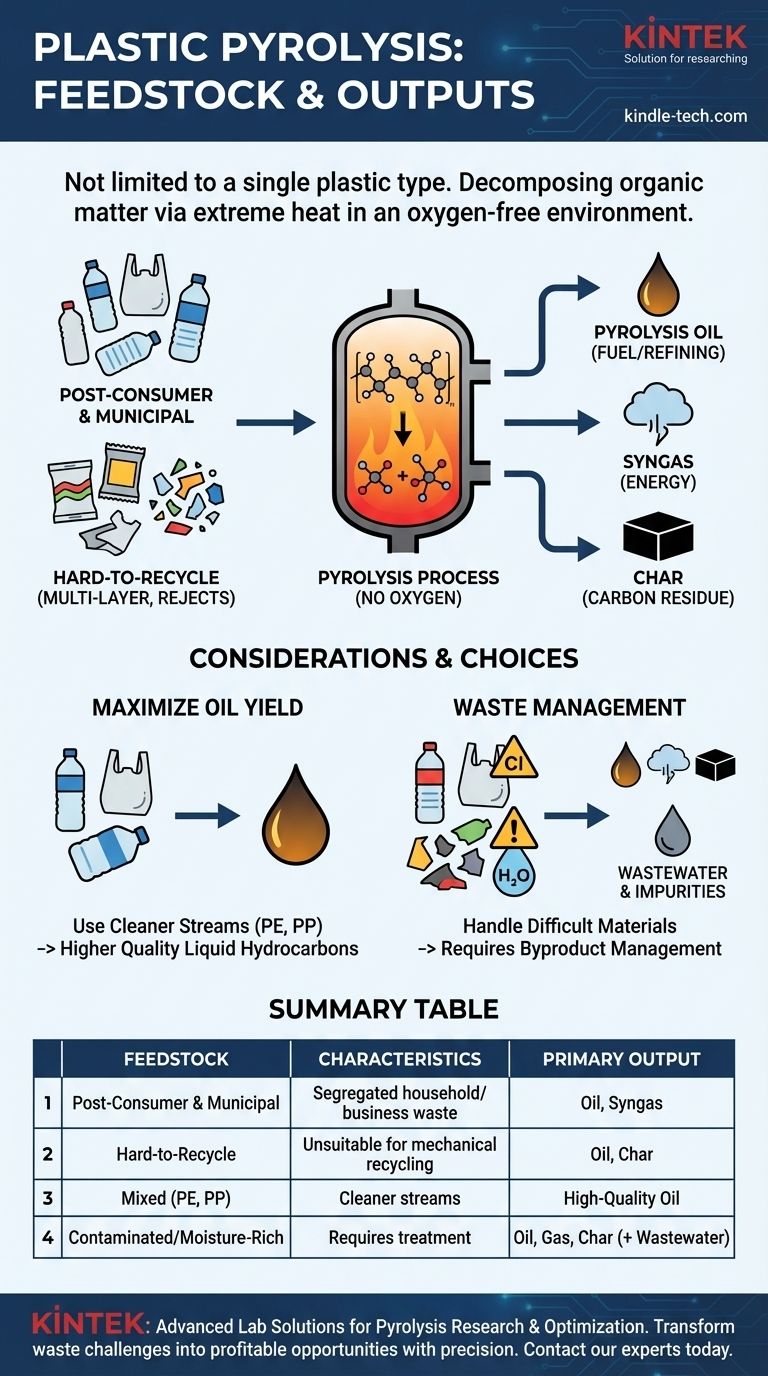

In essence, pyrolysis is not limited to a single type of plastic. The process is designed to handle a wide variety of plastic waste streams, including post-consumer plastics, segregated municipal solid waste, multi-layer packaging, and even mixed plastics that are difficult to recycle mechanically.

The critical factor is not the specific plastic polymer but its nature as an organic material. Pyrolysis works by breaking down these materials at high temperatures in an oxygen-free environment to recover valuable outputs like oil and gas.

The Core Principle: Decomposing Organic Matter

What is Pyrolysis?

Pyrolysis is a thermochemical process that decomposes organic materials using extreme heat in the complete absence of oxygen.

Because there is no oxygen, the material does not combust. Instead, its complex molecules break down into simpler, smaller ones, forming a mix of liquid, gas, and solid char.

Why Plastic is an Ideal Feedstock

Plastics are polymers derived from hydrocarbons, making them a rich source of organic material.

This organic composition is precisely what the pyrolysis process targets. It effectively reverses the production process, breaking down the complex plastic polymers back into valuable, simpler hydrocarbon products like pyrolysis oil.

Suitable Plastic Waste Streams for Pyrolysis

The technology's strength lies in its ability to process diverse and often problematic plastic waste sources.

Post-Consumer & Municipal Plastics

This is the most common feedstock and includes everyday plastic waste generated by households and businesses.

Pyrolysis can handle segregated plastic streams from municipal solid waste (MSW) collection programs, turning a widespread disposal problem into a resource.

Hard-to-Recycle Materials

The process is particularly effective for plastics that mechanical recycling cannot handle. This includes multi-layer packaging (like food pouches) and the reject waste from conventional recycling facilities.

By processing these materials, pyrolysis complements traditional recycling rather than competing with it.

Understanding the Outputs and Trade-offs

The type of plastic feedstock influences the final products and potential challenges. The process is not a perfect conversion and creates byproducts that must be managed.

Primary Outputs: Oil, Gas, and Char

The main goal of plastic pyrolysis is to create pyrolysis oil, a synthetic liquid hydrocarbon that can be used as fuel or further refined.

It also produces pyrolysis gas (syngas), which is often used to power the pyrolysis reactor itself, and a solid residue called char or carbon black.

Handling Contamination and Moisture

While versatile, the process must account for impurities. Feedstocks described as mixed PET/PVC contaminated plastics present challenges, as elements like chlorine in PVC can create corrosive compounds.

Furthermore, any moisture content within the plastic waste will turn into wastewater during the process, which requires proper treatment and handling. This is a critical operational consideration.

Making the Right Choice for Your Goal

Selecting a feedstock is about aligning the available plastic waste with your primary objective.

- If your primary focus is maximizing high-quality oil yield: Aim for cleaner, pre-sorted streams of plastics like Polyethylene (PE) and Polypropylene (PP), as these generally produce more desirable liquid hydrocarbons.

- If your primary focus is waste management for difficult materials: The system is ideal for handling mixed, multi-layer, or contaminated plastics that would otherwise end up in a landfill.

Ultimately, pyrolysis offers a powerful method for turning a wide range of challenging plastic waste into a valuable resource.

Summary Table:

| Suitable Plastic Feedstock | Key Characteristics | Primary Output |

|---|---|---|

| Post-Consumer & Municipal Plastics | Segregated plastic waste from households/businesses | Pyrolysis Oil, Syngas |

| Hard-to-Recycle Materials (e.g., multi-layer packaging, recycling rejects) | Plastics unsuitable for mechanical recycling | Pyrolysis Oil, Char |

| Mixed Plastics (PE, PP, etc.) | Cleaner streams for higher oil yield | High-Quality Pyrolysis Oil |

| Contaminated/Moisture-Rich Plastics | Requires handling of wastewater/impurities | Oil, Gas, Char (with byproduct management) |

Ready to transform your plastic waste challenges into profitable opportunities? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and optimization. Whether you're analyzing feedstock suitability, optimizing oil yields, or managing byproducts, our solutions help you achieve efficient, scalable results. Contact our experts today to explore how we can support your pyrolysis projects with precision and reliability.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is the advantage of pyrolysis? Transforming Waste into High-Value Biofuels and Biochar

- What is the rotary kiln process? A Guide to Efficient High-Temperature Material Processing

- Is pyrolysis the same as waste to energy? Unlocking Chemical Recycling vs. Energy Recovery

- What are the parameters affecting pyrolysis? Master the 4 Key Levers for Optimal Output

- How does pyrolysis machine work? Turn Waste into Valuable Resources with Thermal Decomposition

- How hot is an industrial kiln? The critical temperatures for cement, ceramics, and more.

- What are the temperature stages of pyrolysis? Control Your Output from Biochar to Syngas

- How do you choose calcination temperature? A Guide to Optimizing Material Properties