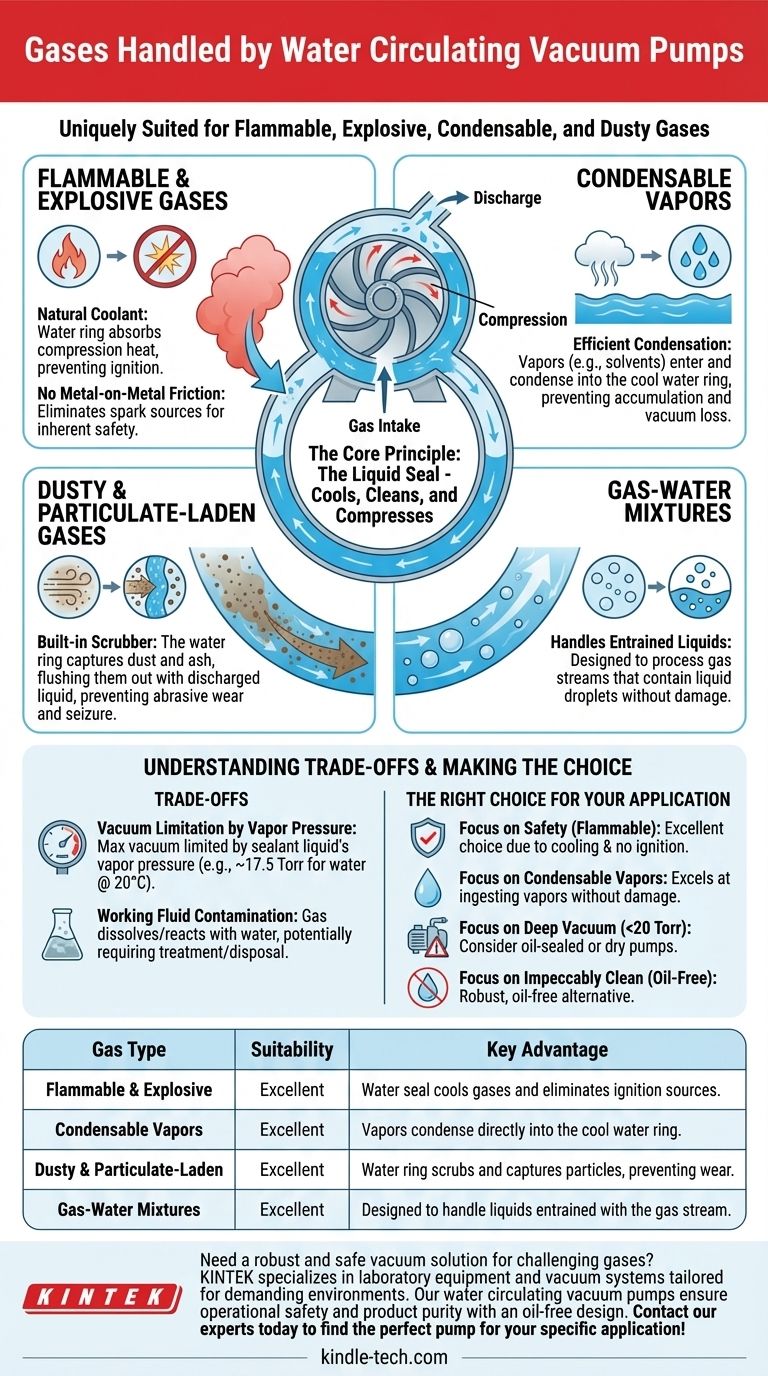

In short, a water circulating vacuum pump can handle a wide variety of challenging gases that would damage or pose a risk to other types of pumps. Its design makes it uniquely suited for flammable, explosive, condensable, and dusty gases, as well as gas-water mixtures, because its operation does not involve high temperatures or friction between internal metal surfaces.

The pump's versatility comes directly from its core design: using a rotating ring of water (or another compatible liquid) to create the vacuum. This liquid seal simultaneously cools, cleans, and compresses the process gas, but its presence also defines the pump's primary limitations.

How a Liquid Ring Enables Gas Versatility

The key is to move away from thinking of it as a traditional mechanical pump and instead see it as a system where liquid does the work. An impeller spins inside a casing, creating a centrifugal force that forms a stable, concentric ring of water against the housing wall.

The Core Principle: The Liquid Seal

Gas is drawn into the space between the impeller hub and the inner surface of the water ring. As the impeller rotates, the pockets of trapped gas are compressed and then discharged, creating the vacuum.

Handling Flammable & Explosive Gases

The constant presence of the water ring serves as a natural coolant. It absorbs the heat of compression, preventing the gas temperature from rising to its autoignition point. Crucially, there are no metal-on-metal friction surfaces that could create a spark, making this design inherently safer for volatile substances.

Managing Condensable Vapors

This is a primary strength. Vapors entering the pump, such as solvents or water vapor from a wet process, simply condense into the much cooler water ring. This prevents the vapor from accumulating and collapsing the vacuum, a common failure mode in dry-sealed pumps.

Pumping Dusty or Particulate-Laden Gases

The water ring acts as a built-in scrubber. Dust, ash, or other small solid particles drawn into the pump are captured by the water. They are then flushed out with the discharged liquid, preventing the abrasive wear and eventual seizure that would destroy pumps with tight mechanical tolerances.

Understanding the Trade-offs

While exceptionally robust, this pump design is not universally optimal. Its strengths come with clear limitations that you must consider for your application.

Vacuum Limitation by Vapor Pressure

The ultimate vacuum a water ring pump can achieve is physically limited by the vapor pressure of the sealing liquid. For water at 20°C (68°F), the vapor pressure is around 17.5 Torr (23.3 mbar). The pump can never achieve a vacuum deeper than this, and in practice, it will be slightly higher. Using colder water improves performance.

Working Fluid Contamination

The very feature that allows the pump to handle difficult gases—the liquid ring—is also a potential liability. The gas being pumped can dissolve into or react with the water. This can contaminate the sealant water, which may then require proper treatment and disposal, adding an operational step.

The "No Oil, No Pollution" Advantage

Unlike oil-sealed rotary vane pumps, water ring pumps present zero risk of oil backstreaming into the vacuum system. For processes in food, pharmaceutical, or semiconductor manufacturing where product purity is paramount, this is a decisive advantage that often outweighs the vacuum limitation.

Making the Right Choice for Your Application

Selecting a pump requires matching its inherent characteristics to your primary goal.

- If your primary focus is safety with flammable gases: A water ring pump is an excellent choice due to its inherent cooling and lack of ignition sources.

- If your primary focus is pumping high loads of condensable vapors: This pump type excels because it can ingest vapors without damage or significant performance loss.

- If your primary focus is achieving a deep vacuum (<20 Torr): You will need to consider other technologies like an oil-sealed rotary vane or a dry scroll pump.

- If your primary focus is an impeccably clean, oil-free process: The water ring pump offers a robust and often lower-cost alternative to dry pumps, completely eliminating oil contamination risk.

Ultimately, understanding the function of the liquid ring is the key to correctly applying this pump's unique strengths to your specific technical challenge.

Summary Table:

| Gas Type | Suitability | Key Advantage |

|---|---|---|

| Flammable & Explosive | Excellent | Water seal cools gases and eliminates ignition sources. |

| Condensable Vapors | Excellent | Vapors condense directly into the cool water ring. |

| Dusty & Particulate-Laden | Excellent | Water ring scrubs and captures particles, preventing wear. |

| Gas-Water Mixtures | Excellent | Designed to handle liquids entrained with the gas stream. |

Need a robust and safe vacuum solution for challenging gases?

KINTEK specializes in laboratory equipment, including vacuum systems tailored for demanding environments. Our water circulating vacuum pumps are ideal for safely handling flammable, condensable, or dirty gases in your lab processes, ensuring operational safety and product purity with an oil-free design.

Contact our experts today to find the perfect pump for your specific application!

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What is the purpose of an immersion chilling accessory? Expand Lab Flexibility and Thermal Range

- What is the importance of an automatic temperature control circulation device? Ensure Reliable Electrochemical Data

- What is the working temperature range of a high-temperature oil bath? Optimize Your High-Heat Lab Processes

- Why are heat exchangers and cooling circulation loops integrated into large-scale water electrolysis systems?

- Why is a high-precision ultra-low temperature cooling system necessary for FATT50? Ensure Precise Material Transition

- What function do thermal oil jackets and temperature control units perform in biomass reactors? Optimize Your Yield.

- Why is a cooling circulation system necessary when simulating SCWO? Protect Your Reactor and Data Integrity

- How does an ultra-low temperature freezer (ULT freezer) ensure data reliability? Preserve Your Research Integrity